Understanding Wood Burning Fireplace Furnaces: A Comprehensive Guide

Wood burning fireplace furnaces represent an alternative heating solution for residential and commercial spaces. These systems aim to improve the efficiency of traditional fireplaces by capturing and distributing a greater percentage of the heat generated from burning wood. Unlike standard fireplaces that primarily radiate heat directly into the surrounding room, wood burning fireplace furnaces utilize a network of ducts or a central heating system to circulate warmed air throughout a building.

The fundamental principle behind a wood burning fireplace furnace is to maximize heat transfer from the wood combustion process. This is achieved through various design features, including enclosed fireboxes, heat exchangers, and forced-air circulation. These components work together to extract as much heat as possible from the burning wood and then distribute it evenly throughout the intended area.

The installation of a wood burning fireplace furnace often involves integrating it into an existing HVAC (Heating, Ventilation, and Air Conditioning) system. Alternatively, some models are designed as standalone units, requiring dedicated ductwork for heat distribution. The choice between these options depends on the specific heating requirements of the building and the existing infrastructure.

Key Point 1: Efficiency and Heat Output

One of the primary advantages of a wood burning fireplace furnace is its potential for increased efficiency compared to a traditional fireplace. Standard fireplaces often have relatively low efficiency ratings, with a significant portion of the heat escaping up the chimney. Wood burning fireplace furnaces, on the other hand, are designed to capture and utilize a greater proportion of the heat produced by combustion. This is accomplished by employing a more controlled burning environment and incorporating heat exchange technology.

The efficiency of a wood burning fireplace furnace is typically measured by its Heating Value (HV). This metric indicates the amount of heat energy released per unit of fuel burned. More efficient furnaces boast higher HV values, signifying more effective heat transfer. Several factors influence the efficiency, including the design of the firebox, the type of wood being burned, and the airflow management system. Seasoned hardwood, for example, generally provides a higher heat output and burns more cleanly than softwoods or unseasoned wood.

Heat output is usually measured in British Thermal Units (BTUs). The required BTU output of a wood burning fireplace furnace depends on the size of the area being heated and the climate. Properly sizing the furnace ensures that it can effectively maintain a comfortable temperature without consuming excessive amounts of wood. Over-sizing can lead to inefficient operation and potential overheating, while under-sizing may not provide adequate heating.

Modern wood burning fireplace furnaces may incorporate features such as catalytic converters or secondary combustion chambers to further enhance efficiency and reduce emissions. Catalytic converters help to burn off unburned gases and particulates, while secondary combustion chambers provide a space for these gases to ignite, further extracting heat and reducing pollutants.

Key Point 2: Types and Features

Wood burning fireplace furnaces come in various designs, each with its own set of features and benefits. One common distinction is between insert models and standalone models. Insert models are designed to be installed within an existing fireplace opening, effectively converting a traditional fireplace into a more efficient heating system. Standalone models, on the other hand, are self-contained units that can be installed in a variety of locations, provided that proper venting and ductwork are in place.

Another key differentiating factor is the type of heat distribution system employed. Some furnaces utilize a forced-air system, which involves a blower fan that circulates heated air through ductwork to different rooms. Others rely on a gravity-fed system, where heated air naturally rises and distributes throughout the space. Forced-air systems offer more precise temperature control and faster heating, while gravity-fed systems tend to be simpler and less reliant on electrical power.

Many wood burning fireplace furnaces feature thermostatic controls, which allow users to regulate the temperature and maintain a consistent level of warmth. Thermostats can be either manual or electronic, with electronic thermostats offering more precise control and potentially incorporating programmable settings. Some models also include safety features such as over-temperature shut-off devices and carbon monoxide detectors.

The materials used in the construction of a wood burning fireplace furnace also play a significant role in its performance and lifespan. Fireboxes are typically constructed from cast iron or steel, both of which offer excellent heat resistance and durability. The exterior panels may be made from a variety of materials, including steel, cast iron, or stone, depending on the desired aesthetic. The quality of the materials and the overall construction can significantly impact the furnace's longevity and overall performance.

The size and capacity of the firebox are also important considerations. A larger firebox allows for longer burn times and reduces the frequency of reloading wood. However, a larger firebox may also require more wood to achieve optimal heating. The optimal size depends on the heating needs of the space and the user's preferences.

Key Point 3: Installation and Maintenance

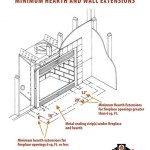

Proper installation is crucial for the safe and efficient operation of a wood burning fireplace furnace. Installation typically involves connecting the furnace to a chimney or flue system, as well as integrating it into the existing ductwork or installing dedicated ductwork. The installation process should be performed by a qualified professional to ensure that all safety codes and regulations are met. Improper installation can lead to serious hazards, including chimney fires and carbon monoxide poisoning.

Regular maintenance is also essential for maintaining the performance and extending the lifespan of a wood burning fireplace furnace. Maintenance tasks typically include cleaning the chimney, inspecting the firebox for cracks or damage, and checking the airflow system for obstructions. The frequency of maintenance depends on the usage of the furnace and the type of wood being burned. Burning unseasoned wood, for example, can lead to creosote buildup in the chimney, which increases the risk of chimney fires.

Chimney cleaning is particularly important for removing creosote, a flammable byproduct of wood combustion that can accumulate in the chimney over time. Creosote buildup can significantly increase the risk of chimney fires, which can be extremely dangerous and difficult to control. Chimney cleaning should be performed by a qualified professional at least once a year, or more frequently if the furnace is used extensively.

The firebox should also be inspected regularly for signs of damage, such as cracks or warping. Cracks in the firebox can compromise the furnace's efficiency and potentially lead to dangerous situations. Any damage should be repaired promptly by a qualified professional. The airflow system should also be checked to ensure that there are no obstructions that could restrict airflow and reduce efficiency.

Proper wood storage is another important aspect of maintenance. Wood should be stored in a dry, well-ventilated area to prevent it from becoming damp or infested with insects. Seasoned wood burns more efficiently and produces less smoke than unseasoned wood. In addition, only untreated wood should be burned in a wood burning fireplace furnace. Burning treated wood can release harmful chemicals into the air.

Adhering to the manufacturer's recommended maintenance schedule and utilizing appropriately seasoned wood are paramount for ensuring optimal performance, safety, and longevity of a wood burning fireplace furnace. Deviations from these guidelines can lead to reduced efficiency, increased risk of hazards, and premature failure of the system.

In summary, wood burning fireplace furnaces offer a potential alternative for heating homes. By understanding their efficiency, types, features, installation and maintenance, it is better to determine if this type of heating is suitable to your needs.

10 Wood Burning Stoves That Will Make You Want To Ditch Your Furnace Cottage Life

Temp Cast Indoor Masonry Fireplace And Oven Combo Patio Outdoor Furnishings

Plans How To Build A Wood Burning Outdoor Furnace Stove

Stoves Wood Gas Pellet Lopi

Freestanding Stove Thor 8 Wood Burning Furnace Kratki

Stoves Wood Gas Pellet Lopi

Temp Cast Masonry Heater Friendly Fires

A Tiny Wood Stove Is The Cozy Glow Heater Your Cabin Needs Sunset

4 Blade Fireplace Furnace Air Blower Heat Powered Wood Stove Fan China Eco Friendly Made In Com

Masonry Heaters Maine Wood Heat Co Inc