Ventless Natural Gas Fireplace Burner: A Comprehensive Overview

Ventless natural gas fireplace burners offer an attractive and convenient alternative to traditional wood-burning fireplaces or vented gas fireplace systems. They provide the ambiance and warmth of a fire without the need for a chimney or vent, making them a popular choice for homes where installing traditional venting systems is impractical or cost-prohibitive. Understanding the functionality, safety features, installation considerations, and maintenance requirements of ventless natural gas fireplace burners is crucial for anyone considering this type of heating appliance.

A ventless natural gas fireplace burner operates by burning natural gas cleanly and efficiently, converting the fuel into heat and minimal byproducts. Because there is no vent to exhaust combustion gases, the burner is designed to burn gas very cleanly, minimizing the production of carbon monoxide, nitrogen dioxide, and other potentially harmful substances. These systems incorporate oxygen depletion sensors (ODS) and other safety mechanisms to ensure safe operation. Understanding how these systems work and the regulations governing their use is key to enjoying their benefits without compromising safety.

Key Point 1: Functionality and Operational Principles

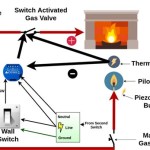

The core principle behind a ventless natural gas fireplace burner is complete combustion. These burners are meticulously engineered to ensure that the natural gas is burned as completely as possible, minimizing the production of unburned hydrocarbons and carbon monoxide. The burner typically consists of a burner pan, a gas valve, a pilot light assembly, and the ODS. The burner pan houses the flames and distributes the heat, while the gas valve regulates the flow of natural gas to the burner. The pilot light provides a continuous ignition source, and the ODS constantly monitors the oxygen levels in the room.

When the fireplace is turned on, the gas valve opens, allowing natural gas to flow to the burner. The pilot light ignites the gas, creating a flame that heats the surrounding air and radiant objects within the room. The design of the burner, including the size and shape of the burner ports, is critical for ensuring even and complete combustion. Manufacturers employ various techniques, such as optimizing the air-to-fuel mixture and using specialized burner materials, to maximize efficiency and minimize emissions.

A critical component is the oxygen depletion sensor (ODS). This safety device constantly monitors the oxygen levels in the room. If the oxygen level drops below a safe threshold, indicating incomplete combustion or inadequate ventilation, the ODS will automatically shut off the gas supply to the burner, preventing the buildup of carbon monoxide. The ODS is a crucial safety feature that distinguishes ventless natural gas fireplace burners from other types of gas appliances.

Modern ventless natural gas fireplace burners are often equipped with electronic ignition systems, eliminating the need for a continuous pilot light. These systems use an electronic spark to ignite the gas when the fireplace is turned on, further improving efficiency and minimizing gas consumption. Some models also include remote controls, allowing users to adjust the flame height and heat output from a distance. These advanced features enhance the convenience and usability of ventless natural gas fireplace burners.

Key Point 2: Safety Features and Regulations

While ventless natural gas fireplace burners are designed for safe operation, adherence to safety guidelines and regulations is paramount. These appliances are subject to stringent testing and certification standards, such as those set by the American National Standards Institute (ANSI) and the Canadian Standards Association (CSA). These standards outline the requirements for burner design, combustion efficiency, and safety features, ensuring that the appliances meet minimum safety requirements.

The ODS is just one of several safety features incorporated into ventless natural gas fireplace burners. Many models also include carbon monoxide detectors, which provide an additional layer of protection by alerting occupants to the presence of elevated carbon monoxide levels. It is highly recommended to install a separate, battery-operated carbon monoxide detector in the room where the fireplace is located, as a backup measure. Regular inspection and maintenance of the carbon monoxide detector are also essential.

Proper ventilation is crucial, even with ventless systems. Although they do not require a chimney, ventless natural gas fireplace burners still consume oxygen and produce combustion byproducts. The use of these appliances in confined spaces with inadequate ventilation can lead to a buildup of carbon monoxide and other harmful gases. Therefore, it is important to follow the manufacturer's recommendations regarding room size and ventilation requirements and to ensure that the room is properly ventilated when the fireplace is in use. Slightly opening a window or door can provide adequate ventilation in many cases.

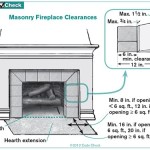

Local building codes and regulations often govern the installation and use of ventless natural gas fireplace burners. These codes may specify restrictions on the size of the fireplace, the location of the fireplace within the room, and the required ventilation. It is essential to consult with local building officials and obtain the necessary permits before installing a ventless natural gas fireplace burner to ensure compliance with all applicable regulations.

Key Point 3: Installation and Maintenance Considerations

Proper installation is critical for the safe and efficient operation of a ventless natural gas fireplace burner. It is highly recommended to have the fireplace installed by a qualified gas technician or HVAC professional who is familiar with the installation requirements and safety precautions. The installation typically involves connecting the burner to the natural gas supply, ensuring proper gas pressure and flow, and verifying the proper operation of the ODS and other safety features.

Before installation, the gas supply line must be inspected to ensure that it is in good condition and that it can provide an adequate supply of natural gas to the burner. The gas pressure must also be checked to ensure that it is within the manufacturer's specified range. Incorrect gas pressure can lead to incomplete combustion and the production of excessive carbon monoxide. The gas technician should perform a leak test after the installation to ensure that there are no gas leaks in the system.

Regular maintenance is essential for maintaining the safe and efficient operation of a ventless natural gas fireplace burner. The burner should be inspected annually by a qualified technician to ensure that it is functioning properly. The pilot light assembly, burner ports, and ODS should be cleaned to remove any debris or carbon buildup that could interfere with combustion. The gas valve and gas supply lines should also be inspected for leaks.

In addition to annual inspections, homeowners should perform regular visual inspections of the fireplace. Check for any signs of damage or corrosion, such as cracks in the burner pan or rust on the gas valve. If any problems are detected, the fireplace should be inspected and repaired by a qualified technician before it is used again. The area around the fireplace should be kept clear of combustible materials, such as furniture, curtains, and paper, to prevent fire hazards.

When cleaning the fireplace, use only mild soap and water. Avoid using abrasive cleaners or solvents, as these can damage the burner components. The glass doors, if present, should be cleaned with a glass cleaner specifically designed for fireplaces. The logs or decorative media should be arranged according to the manufacturer's instructions to ensure proper airflow and combustion. Always follow the manufacturer's instructions for cleaning and maintenance to ensure the longevity and safe operation of the fireplace.

Furthermore, understanding the specific BTU output of the burner is critical for selecting the appropriate size for the room. Over sizing the burner can lead to overheating and inefficient operation, while under sizing can result in inadequate heating. Consulting the manufacturer's recommendations and calculating the room's heating requirements before purchasing a ventless natural gas fireplace burner is essential.

:max_bytes(150000):strip_icc()/ventless-gas-fireplaces-4160746-hero-f9d4bdcd9bd446eb84406de306f790ba.jpg?strip=all)

How To Pick Out A Ventless Gas Fireplace

Radiance Vent Free Gas Stove The Place

24 Valley Oak Vent Free Log G8 Ansi Bedroom Approved Burner Peterson Real Fyre

Napoleon Gvfl30 Ventless Gas Log Set 30 Inch

Kingsman 24 Vent Free Gas Burner Glvf24 Us Fireplace

Ventless Gas Fireplace Vent Free Modern

Duluth Forge Dual Fuel Ventless Gas Fireplace 26 000 Btu Remote Control Auburn Cherry Finish 170106 The Home Depot

Monessen Nbst27 Natural Blaze See Through 27 Inch Vent Free Gas Log Set

Duluth Forge Dual Fuel Ventless Gas Fireplace 26 000 Btu T Stat Control Auburn Cherry Finish Com

Empire Vent Free Stove Bedroom Approved Fine S Gas

Related Posts