Ventless LP Fireplaces: A Comprehensive Guide

Ventless, or vent-free, liquid propane (LP) fireplaces offer a heating and aesthetic solution for spaces where traditional vented fireplaces are impractical or impossible to install. These appliances burn propane directly within the living space, converting nearly all of the fuel into heat. The design eliminates the need for a chimney or flue, providing flexibility in placement and installation. However, understanding the technology, safety features, and operational considerations is vital for homeowners considering this type of fireplace.

The functionality of a ventless LP fireplace relies on carefully controlled combustion. These fireplaces are designed to burn propane with a very high degree of efficiency, typically exceeding 99%. This efficient combustion minimizes the production of harmful byproducts, which include carbon monoxide, nitrogen dioxide, and water vapor. Because these byproducts are released directly into the room, stringent safety measures are incorporated into the design and operation.

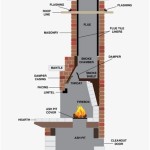

The primary distinction between ventless and vented fireplaces lies in the exhaust system. Vented fireplaces require a chimney or flue to expel combustion byproducts outside the home. Ventless models, conversely, use room air for combustion and release the byproducts directly into the living space. This difference significantly impacts installation complexity, cost, and energy efficiency.

Key Point 1: Understanding the Safety Features of Ventless LP Fireplaces

Safety is paramount when considering ventless LP fireplaces. These appliances are equipped with several crucial safety features designed to mitigate the risks associated with indoor combustion. The most important of these is the Oxygen Depletion Sensor (ODS).

The ODS is a critical component that continuously monitors the oxygen level in the room. As the fireplace burns, it consumes oxygen. If the oxygen level falls below a predetermined threshold, typically around 18%, the ODS automatically shuts off the gas supply to the fireplace. This prevents the fireplace from continuing to burn in an oxygen-depleted environment, which could lead to the production of dangerous levels of carbon monoxide.

The ODS functions by monitoring a pilot flame. As long as the oxygen concentration in the surrounding air is sufficient, the pilot flame remains stable and heats a thermocouple. The thermocouple generates a small electrical current that keeps the gas valve open. When the oxygen level drops, the pilot flame weakens, the thermocouple cools, and the electrical current decreases. This triggers the gas valve to close, shutting off the fuel supply to the fireplace.

In addition to the ODS, many ventless LP fireplaces incorporate additional safety features such as automatic shut-off timers and overheat sensors. Automatic shut-off timers are designed to turn off the fireplace after a predetermined period, typically several hours. This prevents the fireplace from being left on unattended for extended periods. Overheat sensors monitor the temperature of the fireplace and shut it off if it exceeds a safe operating limit.

Regular maintenance is essential for ensuring the continued proper functioning of these safety features. This includes cleaning the burner and pilot light assembly to prevent debris from interfering with the combustion process. It also involves periodically checking the ODS and other safety devices to ensure they are operating correctly. Homeowners should consult the manufacturer's instructions for specific maintenance recommendations.

It is also crucial to adhere to the manufacturer's recommendations regarding room size and ventilation. Ventless fireplaces are sized for specific room volumes, and operating a fireplace that is too large for the room can lead to oxygen depletion and an increase in humidity levels. Adequate ventilation is essential to help dissipate moisture and maintain air quality. This can be achieved by opening a window or using an exhaust fan.

Key Point 2: Proper Installation and Ventilation Considerations

The safe and efficient operation of a ventless LP fireplace hinges on proper installation and adequate ventilation. Installation should always be performed by a qualified professional who is familiar with local building codes and manufacturer’s specifications.

The installation process involves connecting the fireplace to a propane supply line. This requires careful attention to gas line integrity and leak testing. The gas line must be properly sized to provide adequate fuel flow to the fireplace. All connections must be made according to industry standards and local regulations.

The fireplace should be installed on a non-combustible surface, such as tile or concrete. Combustible materials, such as carpeting or wood flooring, should be kept a safe distance from the fireplace. The manufacturer's instructions will specify the minimum clearance requirements for combustible materials.

Ventilation is a critical aspect of ventless fireplace operation. While these fireplaces do not require a chimney or flue, they do require adequate room ventilation to ensure air quality and prevent moisture buildup. The amount of ventilation required depends on the size of the fireplace and the size of the room. As a general guideline, a ventless fireplace should not be used in a room that is smaller than the manufacturer's specified minimum size.

Proper ventilation can be achieved by opening a window or using an exhaust fan. The amount of window opening required will vary depending on the size of the fireplace and the room. The manufacturer's instructions may provide specific recommendations for ventilation. If using an exhaust fan, it should be located in the same room as the fireplace and should be capable of removing a sufficient volume of air.

The water vapor produced by the combustion process can increase humidity levels inside the home. High humidity can lead to mold growth and other moisture-related problems. Proper ventilation helps to dissipate moisture and maintain a comfortable indoor environment.

Local building codes may have specific requirements for the installation and operation of ventless LP fireplaces. Homeowners should consult with their local building department to ensure compliance with all applicable regulations. Failure to comply with building codes can result in fines and other penalties.

Key Point 3: Maintenance and Operational Best Practices

Regular maintenance and adherence to operational best practices are crucial for ensuring the longevity, safety, and efficiency of a ventless LP fireplace. Maintenance should include regular cleaning, inspections, and component replacements as needed.

The burner and pilot light assembly should be cleaned periodically to remove dust, debris, and carbon deposits. This can be done using a soft brush and a vacuum cleaner. Accumulated debris can interfere with the combustion process and reduce the efficiency of the fireplace. It can also pose a safety hazard.

The ODS should be inspected regularly to ensure it is functioning correctly. This can be done by testing the fireplace in a slightly oxygen-depleted environment. If the ODS fails to shut off the gas supply, it should be replaced immediately. A malfunctioning ODS can pose a serious safety risk.

The gas line should be inspected periodically for leaks. This can be done using a soapy water solution. If bubbles form on any of the gas line connections, it indicates a leak. The leak should be repaired immediately by a qualified professional.

The fireplace should be operated according to the manufacturer's instructions. Overloading the fireplace or using it in a manner that is not recommended can damage the unit and pose a safety hazard. Never use flammable liquids, such as gasoline or kerosene, to start or operate the fireplace.

The area around the fireplace should be kept clear of combustible materials. This includes furniture, curtains, and paper products. Combustible materials should be kept a safe distance from the fireplace to prevent fire hazards.

Carbon monoxide detectors should be installed in the home, especially near the fireplace. Carbon monoxide is a colorless, odorless gas that can be produced by incomplete combustion. High levels of carbon monoxide can be deadly. Carbon monoxide detectors provide an early warning of dangerous carbon monoxide levels, allowing occupants to evacuate the building safely.

Homeowners should be aware of the signs of carbon monoxide poisoning, which can include headache, dizziness, nausea, and shortness of breath. If anyone in the home experiences these symptoms, they should immediately evacuate the building and seek medical attention.

By following these maintenance and operational best practices, homeowners can ensure the safe and efficient operation of their ventless LP fireplace for many years to come. Always prioritize safety and consult with a qualified professional for any installation, maintenance, or repair work.

:max_bytes(150000):strip_icc()/ventless-gas-fireplaces-4160746-hero-f9d4bdcd9bd446eb84406de306f790ba.jpg?strip=all)

How To Pick Out A Ventless Gas Fireplace

Duluth Forge Dual Fuel Ventless Gas Fireplace 26 000 Btu Remote Control Antique White Finish 170105 The Home Depot

Ventless Gas Fireplace Propane

Radiance Vent Free Gas Stove The Place

Pleasant Hearth 27 500 Btu 42 In Convertible Ventless Propane Gas Fireplace Heritage Vff Ph26lp 2h2 The Home Depot

The Debate Continues Are Ventless Fireplaces Safe

Bluegrass Living 55 In Black Ventless Liquid Propane Gas Fireplace The Fireplaces Department At Com

Superior 42 Inch Vrt3500 Series Vent Free Gas Fireplace Firebox

Regal Flame 5 Piece 16 Inch Ceramic Wood Gas Fireplace Logs For All Types Of Indoor Inserts Ventless Vent Free Propane Gel Ethanol Electric Or Outdoor Fireplaces Fire Pits

Vent Free White Mountain Hearth

Related Posts