Vented Natural Gas Fireplace Heaters: An In-Depth Examination

Vented natural gas fireplace heaters represent a popular and efficient method for providing supplemental heating in residential and commercial spaces. Unlike ventless models, vented fireplaces necessitate a chimney or vent system to expel combustion byproducts safely to the outside environment. This fundamental difference significantly impacts the installation process, safety considerations, and overall performance of the unit. A thorough understanding of the operational principles, advantages, disadvantages, and maintenance requirements of vented natural gas fireplace heaters is crucial for informed decision-making when selecting and utilizing this type of heating appliance.

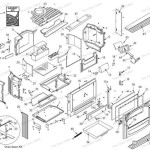

The core functionality of a vented natural gas fireplace heater centers on the combustion of natural gas to generate heat. Natural gas, primarily composed of methane, is supplied to the fireplace through a gas line. Within the firebox, a burner system mixes the gas with air, and an ignition system initiates combustion. The resulting flame heats the surrounding refractory materials, such as ceramic logs or decorative elements, which then radiate heat into the room. The combustion process produces exhaust gases, including carbon dioxide, water vapor, and trace amounts of other byproducts. The venting system, typically a chimney or specialized vent pipe, facilitates the safe and effective removal of these gases from the interior space.

Vented natural gas fireplaces offer a range of aesthetic options. They can mimic the appearance of traditional wood-burning fireplaces with realistic log sets and flickering flames. Alternatively, contemporary designs feature sleek glass fronts and modern burner configurations. The selection of a specific aesthetic style is often dependent on the homeowner's preferences and the overall décor of the room.

Enhanced Safety Features of Vented Systems

The primary advantage of vented natural gas fireplace heaters lies in their enhanced safety profile compared to ventless models. The presence of a venting system ensures that combustion byproducts are effectively removed from the living space, minimizing the risk of indoor air pollution. Carbon monoxide, a colorless and odorless gas produced by incomplete combustion, poses a significant health hazard. Vented systems significantly reduce the potential for carbon monoxide buildup within the home, contributing to a safer indoor environment. This is particularly important for individuals with respiratory sensitivities or pre-existing health conditions.

Furthermore, vented fireplaces typically incorporate safety features such as oxygen depletion sensors (ODS). These sensors monitor the oxygen levels within the firebox and automatically shut off the gas supply if oxygen levels drop below a predetermined threshold. This safety mechanism helps prevent incomplete combustion and the subsequent production of carbon monoxide. Regular inspection and maintenance of the ODS system are essential to ensure its proper functionality.

The design of vented fireplaces also addresses concerns related to moisture buildup. The venting process helps remove water vapor produced during combustion, preventing excessive humidity within the home. This is particularly beneficial in climates with high humidity levels, where excessive moisture can contribute to mold growth and other indoor air quality issues.

Installation and Venting Considerations

The installation of a vented natural gas fireplace heater is generally more complex and costly than the installation of a ventless model. The presence of a venting system necessitates careful planning and execution to ensure proper function and compliance with local building codes. The venting system must be appropriately sized and configured to effectively remove exhaust gases without creating backdrafting or other performance issues. Incorrect installation can lead to dangerous conditions, including carbon monoxide poisoning and fire hazards.

Several venting options are available for vented natural gas fireplaces, including traditional chimneys, B-vent systems, and direct-vent systems. Traditional chimneys are typically constructed of brick or masonry and require regular inspection and maintenance to ensure structural integrity. B-vent systems are double-walled metal pipes designed for venting appliances that produce relatively low exhaust temperatures. Direct-vent systems utilize sealed combustion chambers that draw air from outside the home and exhaust gases directly to the exterior. Direct-vent systems offer greater flexibility in terms of placement and are particularly well-suited for installations where a traditional chimney is not available or feasible.

Regardless of the venting system chosen, it is crucial to ensure that it is properly connected to the fireplace and that all joints are sealed tightly to prevent leaks. Regular inspection of the venting system is recommended to identify any signs of damage or deterioration. Obstructions within the venting system, such as bird nests or debris, can impede airflow and compromise the safety and efficiency of the fireplace. Professional installation by a qualified technician is strongly recommended to ensure that the venting system is installed correctly and in accordance with all applicable codes and regulations.

Efficiency and Operational Characteristics

The efficiency of a vented natural gas fireplace heater is generally lower than that of a ventless model. Because a portion of the heat generated by the fireplace is lost through the venting system, the overall heating efficiency is reduced. However, the enhanced safety features of vented systems often outweigh the lower efficiency for many homeowners. The amount of heat that escapes through the vent is dependent on the fireplace's design and the efficiency of the vent system itself. Some high-efficiency vented fireplaces use advanced technologies to minimize heat loss and maximize energy savings.

Vented fireplaces typically require a larger gas supply than ventless models due to the continuous venting of heated air. This can result in higher energy bills over time. However, the operating costs can be offset by the supplemental heating provided by the fireplace, allowing homeowners to reduce the reliance on central heating systems and potentially lower overall heating expenses. The energy efficiency of a vented natural gas fireplace can be influenced by factors such as the insulation of the room, the size of the fireplace, and the frequency of use.

The operational characteristics of vented natural gas fireplaces also include the potential for drafts. The venting system can create a negative pressure within the room, drawing cold air in from outside. To mitigate this effect, it is important to ensure that the room is properly insulated and that any gaps or cracks around windows and doors are sealed. Some vented fireplaces incorporate features such as dampers or adjustable vents to control airflow and minimize drafts.

Pilot lights are a common feature in many vented natural gas fireplaces. The pilot light is a small, continuous flame that ignites the main burner when the fireplace is turned on. While pilot lights consume a small amount of gas, they can contribute to energy waste over time. Some newer models feature electronic ignition systems that eliminate the need for a pilot light, resulting in greater energy efficiency. Alternatively, some fireplaces use standing pilots that can be turned off manually during periods of non-use to conserve energy.

The heat output of a vented natural gas fireplace is typically measured in British thermal units (BTUs). The appropriate BTU rating for a particular fireplace depends on the size of the room and the desired level of heating. A higher BTU rating indicates a greater heat output. It is important to select a fireplace with a BTU rating that is appropriate for the intended application to avoid overheating or underheating the space.

Maintenance and Care Requirements

Regular maintenance is essential to ensure the safe and efficient operation of a vented natural gas fireplace heater. The frequency of maintenance depends on the usage of the fireplace and the manufacturer's recommendations. Routine maintenance tasks include cleaning the burner system, inspecting the venting system, and ensuring that the safety features are functioning properly. Failure to perform regular maintenance can lead to performance issues, safety hazards, and reduced lifespan of the appliance.

Cleaning the burner system involves removing any debris or soot that may have accumulated on the burner ports. Clogged burner ports can impede airflow and result in incomplete combustion. A soft brush or vacuum cleaner can be used to remove debris from the burner system. It is important to follow the manufacturer's instructions carefully when cleaning the burner system to avoid damaging any components.

Inspecting the venting system involves visually examining the chimney or vent pipe for any signs of damage or deterioration. Cracks, leaks, or corrosion can compromise the integrity of the venting system and create a safety hazard. If any damage is detected, it should be repaired promptly by a qualified technician. Regular chimney sweeping is also recommended to remove any creosote or other buildup that may have accumulated within the chimney flue. Creosote is a highly flammable substance that can pose a fire hazard if allowed to accumulate in the chimney. The frequency of chimney sweeping depends on the usage of the fireplace and the type of fuel burned.

Testing the safety features, such as the oxygen depletion sensor (ODS), is an important part of regular maintenance. The ODS should be tested periodically to ensure that it is functioning properly. Instructions for testing the ODS can be found in the manufacturer's manual. If the ODS is not functioning properly, it should be replaced immediately.

In addition to routine maintenance, it is also important to schedule professional inspections of the fireplace and venting system periodically. A qualified technician can identify any potential problems that may not be readily apparent and perform any necessary repairs or adjustments. Professional inspections can help ensure the safe and efficient operation of the fireplace for many years to come.

Intrepid Direct Vent Gas Stove The Place

Gas Fireplaces Inserts Stoves And Heaters The Hearth

Oxford Direct Vent Gas Stove The Place

Heat N Glo Paloma Direct Vent Gas Stove

31 1 4 X 16 5 8 21 2 17000 To 26000 Btu Hr 36 7 54 Kw 40 Npt Natural Gas Fireplace Heater Direct Vent Insert Design Air

Napoleon Arlington Direct Vent Cast Iron Gas Stove

Freestanding High Efficiency Direct Vent Gas Fireplaces Inserts Stoves Godby Hearth And Home

Direct Vent Stoves Inserts Fireplaces Northern Va Winson S

Pleasant Hearth 30 000 Btu 32 In Intermediate Vent Free Gas Stove Fireplace Doors

23 500 Btu Vented Dual Fuel Cast Iron Gas Stove Heater Ag23 The Home Depot

Related Posts