Vent Pipe for Gas Fireplace: A Comprehensive Guide

Gas fireplaces offer a convenient and aesthetically pleasing alternative to traditional wood-burning fireplaces. Their ease of use and relatively clean operation have made them a popular choice for many homeowners. However, proper venting is crucial for the safe and efficient functioning of a gas fireplace. The vent pipe, often overlooked, plays a vital role in removing combustion byproducts from the living space and ensuring a healthy indoor environment. Understanding the various types, installation requirements, and maintenance needs of gas fireplace vent pipes is essential for both homeowners and professionals involved in their installation and upkeep.

The primary function of a gas fireplace vent pipe is to expel harmful gases like carbon monoxide, water vapor, and other combustion products generated during the burning of gas. Proper venting prevents these gases from accumulating inside the house, which can lead to serious health problems, including carbon monoxide poisoning. The design and installation of the vent pipe directly impact the fireplace's efficiency, combustion quality, and overall safety. A properly sized and installed vent pipe ensures that the fireplace operates as intended, providing warmth and ambiance without compromising the air quality within the home.

Types of Gas Fireplace Vent Pipes

The type of vent pipe required for a gas fireplace depends on the fireplace itself, its location within the home, and local building codes. There are mainly three types of gas fireplace vent systems: natural vent, direct vent, and vent-free (or ventless). While vent-free systems exist, their usage is subject to strict regulations and may not be permitted in all jurisdictions due to concerns about indoor air quality and oxygen depletion. Here we focus on the first two, which are the most common and safest options.

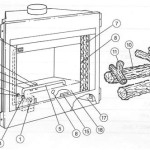

Natural Vent (B-Vent): Natural vent systems, also known as B-vents, rely on natural convection to exhaust flue gases. These systems typically consist of double-walled metal pipes that connect to the fireplace and extend vertically through the roof. The heat from the combustion process creates a draft that pulls the exhaust gases upwards and out of the house. B-vents are typically used with natural gas fireplaces and are suitable for installations where a vertical vent run is possible. The height and diameter of the vent pipe are crucial for creating sufficient draft. Building codes specify the minimum and maximum height requirements for B-vents to ensure proper performance.

B-vents are characterized by their relatively simple design and lower cost compared to direct vent systems. However, they are less energy-efficient because they draw air from the room for combustion, which then goes up the vent. This can result in heat loss, increasing overall heating costs. Furthermore, B-vents are susceptible to backdrafting if the chimney is not properly sized or if there are obstructions in the vent pipe. Backdrafting occurs when the flue gases flow back into the house instead of being exhausted outside, posing a significant safety hazard.

Direct Vent: Direct vent systems are sealed combustion systems that draw air from outside the house for combustion and exhaust flue gases directly to the outside. This type of system uses two concentric pipes: one pipe draws in fresh air, and the other expels exhaust gases. Direct vent fireplaces are more versatile than natural vent fireplaces because they can be vented horizontally through a wall or vertically through the roof. This allows for greater flexibility in fireplace placement, as they do not require an existing chimney.

Direct vent systems are more energy-efficient than natural vent systems because they do not use air from inside the house for combustion. This prevents heat loss and reduces drafts. Direct vent fireplaces are also safer because the combustion process is sealed off from the interior of the home, minimizing the risk of carbon monoxide poisoning. The sealed design also prevents outside air from entering the house, improving indoor air quality. The vent pipes used in direct vent systems are typically constructed of aluminum or stainless steel and are designed to withstand high temperatures and corrosive flue gases. The installation of direct vent systems requires careful attention to detail to ensure a proper seal and prevent leaks.

Choosing between a natural vent and a direct vent system depends on several factors, including the type of fireplace, the location of the fireplace, the available venting options, and local building codes. Direct vent systems are generally preferred for their safety and energy efficiency, but natural vent systems may be a viable option in certain situations where a vertical vent run is possible and energy efficiency is less of a concern.

Installation Requirements for Gas Fireplace Vent Pipes

Proper installation of gas fireplace vent pipes is critical for safe and efficient operation. Incorrect installation can lead to dangerous conditions, including carbon monoxide poisoning, fire hazards, and reduced fireplace performance. Installation should always be performed by a qualified professional who is familiar with local building codes and manufacturer's instructions. This section outlines some of the key installation requirements for gas fireplace vent pipes.

Proper Sizing: The diameter and length of the vent pipe must be properly sized according to the manufacturer's specifications and local building codes. Undersized vent pipes can restrict airflow and lead to incomplete combustion, resulting in carbon monoxide production. Oversized vent pipes can cause excessive cooling of the flue gases, leading to condensation and corrosion. The sizing requirements depend on several factors, including the fireplace's BTU input, the height of the vent pipe, and the number of elbows in the vent run.

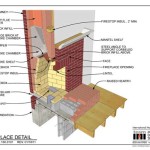

Adequate Clearance: Vent pipes must maintain adequate clearance from combustible materials, such as wood framing, insulation, and drywall. The minimum clearance requirements are specified in building codes and manufacturer's instructions. Insufficient clearance can lead to overheating and potentially cause a fire. Non-combustible materials, such as metal shields or air gaps, can be used to reduce the clearance requirements in certain situations.

Proper Sealing: Vent pipes must be properly sealed to prevent leaks. Leaks can allow flue gases to escape into the house, posing a health hazard. All joints and connections should be sealed with high-temperature sealant or tape specifically designed for use with gas fireplace vent pipes. The sealant must be resistant to the corrosive effects of flue gases and be able to withstand high temperatures.

Correct Slope and Support: Vent pipes should be installed with the correct slope to allow condensation to drain back into the fireplace. The recommended slope is typically ¼ inch per foot. The vent pipe must also be properly supported to prevent sagging or damage. Supports should be spaced according to the manufacturer's instructions and should be securely attached to the building structure.

Termination Requirements: The vent pipe must terminate in a location that meets building code requirements. The termination point should be located away from windows, doors, and air intakes to prevent flue gases from entering the house. The vent pipe should also be protected from the elements, such as rain and snow. Termination caps or rain caps are often used to prevent water from entering the vent pipe.

Inspection and Testing: After installation, the vent pipe should be inspected and tested to ensure that it is functioning properly. A visual inspection can identify any obvious defects or leaks. A draft test can verify that the vent pipe is drawing flue gases properly. A carbon monoxide detector should be installed in the home to provide an early warning of any potential problems. An annual professional inspection is also recommended to ensure the vent pipe remains in good condition.

Maintenance and Troubleshooting of Gas Fireplace Vent Pipes

Regular maintenance of gas fireplace vent pipes is essential for ensuring their safe and efficient operation. Neglecting maintenance can lead to problems such as blockages, corrosion, and leaks, which can compromise the performance of the fireplace and create safety hazards. This section outlines some of the key maintenance tasks and troubleshooting tips for gas fireplace vent pipes.

Regular Inspection: Inspect the vent pipe regularly for signs of damage, such as cracks, corrosion, or sagging. Check the joints and connections for leaks. Look for any debris or obstructions that may be blocking the vent pipe. Early detection of problems can prevent them from escalating into more serious issues.

Cleaning: Clean the vent pipe periodically to remove any buildup of soot, dust, or other debris. A soft brush or vacuum cleaner can be used to clean the interior of the vent pipe. Be careful not to damage the vent pipe during the cleaning process. A professional chimney sweep can provide a more thorough cleaning if necessary.

Obstruction Removal: Remove any obstructions that may be blocking the vent pipe. Common obstructions include bird nests, leaves, and other debris. A blockage can restrict airflow and lead to incomplete combustion and carbon monoxide production. A chimney cap can help prevent birds and other animals from nesting in the vent pipe.

Leak Repair: Repair any leaks in the vent pipe immediately. Leaks can allow flue gases to escape into the house, posing a health hazard. Use high-temperature sealant or tape specifically designed for use with gas fireplace vent pipes to seal any leaks. If the leak is severe, the vent pipe may need to be replaced.

Draft Problems: If the fireplace is not drafting properly, it may be due to a problem with the vent pipe. Check for obstructions in the vent pipe. Ensure that the vent pipe is properly sized and installed. Consider adding a chimney extension to increase the height of the vent pipe and improve the draft. A professional inspection can help identify the cause of the draft problem and recommend the appropriate solution.

Condensation Issues: Excessive condensation in the vent pipe can lead to corrosion and damage. Ensure that the vent pipe is properly insulated to prevent cooling of the flue gases. Check for leaks in the vent pipe that may be allowing water to enter. Consider installing a condensation drain to remove excess moisture from the vent pipe.

Carbon Monoxide Detection: Install a carbon monoxide detector in the home to provide an early warning of any potential problems. Test the detector regularly to ensure that it is functioning properly. If the detector alarms, evacuate the house immediately and call the fire department. Do not use the fireplace until the source of the carbon monoxide leak has been identified and repaired.

By following these maintenance and troubleshooting tips, homeowners can ensure that their gas fireplace vent pipes are functioning safely and efficiently. Regular maintenance can prevent problems from escalating into more serious issues and prolong the life of the vent pipe. If any problems are detected, it is important to consult a qualified professional for assistance.

Gas Fireplace Venting Explained Heatilator

Gas Fireplace Venting Explained Heat Glo

What Are The Best Ways To Vent A Gas Fireplace Zoroast

Benefits Of Direct Vent Fireplaces

Gas Fireplace Venting Explained Heat Glo

Vented Vs B Vent Direct Free Dixie S

What Is A Direct Vent Fireplace Fireplaces Learning Center

How To Guide Using Fireplace Flex Vent North Country Fire

Direct Vent B Gas Free S Mazzeo Stoves Fireplaces

Napoleon 4 X 7 Venting 16 Nap 4x7 Chimney S Hvacdirect Com