Stone Fireplace Facade: A Do-It-Yourself Guide

A fireplace serves as a focal point in many homes, providing warmth and visual appeal. Over time, the existing facade may become outdated, damaged, or simply no longer align with the homeowner's aesthetic preferences. Instead of a complete fireplace overhaul, resurfacing with a stone facade offers a cost-effective and visually striking alternative. This article provides a comprehensive guide to installing a stone fireplace facade as a do-it-yourself project, outlining the necessary steps, tools, and considerations for successful implementation.

Planning and Preparation: Laying the Foundation for Success

Before commencing any physical work, meticulous planning is critical. This stage involves evaluating the existing fireplace structure, selecting the appropriate stone material, and preparing the workspace. A thorough approach at this juncture minimizes potential complications and ensures a professional-looking outcome.

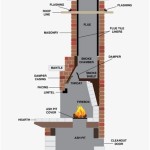

The initial step involves a comprehensive inspection of the existing fireplace. Assess the condition of the existing facade, noting any cracks, loose bricks, or structural weaknesses. If significant damage is present, professional consultation may be necessary to address underlying structural issues before proceeding with the stone facade installation. The existing facing material must be properly prepared to ensure proper adhesion of the new stone. This requires the removal of any loose debris, paint, or wallpaper. A wire brush can be used to scrub away surface contaminants. In some cases, it may be necessary to apply a bonding agent to the existing surface to promote adhesion.

Selecting the appropriate stone material is a critical decision. Options range from natural stone veneers to manufactured stone products. Natural stone offers unique textures and variations, but is often more expensive and heavier than manufactured alternatives. Manufactured stone, made from concrete or other composite materials, provides a more uniform appearance, lighter weight, and reduced cost. The choice depends on budget, aesthetic preferences, and the structural capacity of the existing fireplace. Consider the style, color, and texture of the stone to complement the surrounding decor. Obtain samples to visualize how the stone will appear in the room's lighting conditions.

Accurate measurements are essential for efficient material ordering and installation. Measure the height and width of the existing fireplace facade, and calculate the total surface area to be covered with stone. Add an extra 10-15% to this figure to account for cuts, waste, and potential errors. This overage will prevent material shortages during the installation process. When ordering materials, ensure the supplier provides detailed instructions on proper installation techniques specific to the chosen stone type. These instructions may include recommendations for mortar type, joint size, and sealing procedures. It is highly recommended to create a detailed layout plan. This plan outlines the placement of each stone, taking into account the desired aesthetic and minimizing the need for excessive cutting. A well-defined layout simplifies the installation process and reduces material waste.

Preparing the workspace involves gathering all necessary tools and materials, protecting surrounding areas, and ensuring adequate ventilation. Assemble tools such as a trowel, mixing bucket, level, chisel, hammer, wet saw (for cutting stone), safety glasses, gloves, and a dust mask. Cover floors and furniture with drop cloths to protect them from mortar splatters and dust. Ensure adequate ventilation by opening windows or using a fan, especially when mixing mortar or applying sealants. Proper ventilation minimizes exposure to harmful fumes and dust particles. Finally, review all product safety data sheets (SDS) for any materials being used. Understand potential hazards and take necessary precautions to protect yourself from harm.

Installation Procedure: Applying the Stone Facade

The installation process involves several key steps, including mortar preparation, stone application, and joint finishing. Each step requires careful attention to detail to ensure a durable and aesthetically pleasing result.

Mortar acts as the adhesive that binds the stone to the existing surface. Choosing the correct mortar is vital. Utilize a mortar specifically designed for stone veneer applications. These mortars typically offer improved adhesion and water resistance compared to standard mortars. Follow the manufacturer's instructions for mixing the mortar. Typically, this involves adding water to a dry mortar mix in the correct ratio. Use a mixing bucket and trowel to achieve a smooth, consistent consistency. Avoid adding too much water, as it can weaken the mortar's bonding strength. Apply a generous layer of mortar to the back of each stone using a trowel. The mortar layer should be thick enough to create a strong bond and compensate for any slight irregularities in the wall surface. However, avoid applying excessive mortar, as it can squeeze out between the stones and create a messy appearance.

Begin applying the stones, starting from the bottom and working upwards. Press each stone firmly against the prepared surface, ensuring good contact with the mortar. Use a level to ensure that the stones are aligned horizontally and vertically. Adjust the placement of the stones as needed while the mortar is still pliable. Maintain consistent joint spacing between the stones. The desired joint size depends on the aesthetic preference and the type of stone being used. Typically, joint widths range from ½ inch to 1 inch. Use spacers or pre-cut shims to maintain consistent joint spacing during the installation process. If cutting stones is necessary, use a wet saw equipped with a diamond blade. Wet saws minimize dust generation and provide clean, precise cuts. Always wear safety glasses and a dust mask when operating a wet saw. Once the stones have been placed, allow the mortar to cure for the recommended time period as specified by the manufacturer. Avoid disturbing the stones during the curing process to ensure a strong bond.

After the mortar has cured, the joints need to be finished. The method used depends on the desired look, and the type of stone. There are mainly two joint mortar types: grouted and dry-stacked. For grouted joints, apply mortar to the joints using a grout bag or a small trowel. Ensure that the mortar fills the joints completely and is flush with the surface of the stone. Use a jointing tool to create a smooth, consistent joint profile. Common joint profiles include concave, v-shaped, and flush. For dry-stacked joints, no grout is applied. A dry-stacked joint will require that stones fit tightly to one another. After the jointing process is complete, clean any excess mortar from the face of the stones using a damp sponge. Be careful not to disturb the mortar in the joints. Once the mortar has fully cured, apply a stone sealer to protect the stone from moisture damage and stains. Follow the manufacturer's instructions for applying the sealer. Perform all maintenance tasks and follow recommendations from the stone manufacturer.

Addressing Common Challenges: Troubleshooting the Installation Process

Even with careful planning and preparation, unexpected challenges can arise during the stone facade installation process. Addressing these challenges effectively minimizes delays and ensures a successful outcome.

Achieving proper adhesion is essential for a durable stone facade. If stones are not adhering properly, several factors could be at play. The existing surface may not have been adequately prepared, or the mortar may not have been mixed correctly. Ensure that the surface is clean, free of debris, and properly primed with a bonding agent. Remake the mortar, ensuring that it is mixed to the correct consistency and is compatible with the stone type. In some cases, the stone itself may be contaminated with dust or dirt. Clean the back of the stones thoroughly before applying mortar. To ensure a strong bond, it may be necessary to temporarily support the stones with shims or braces until the mortar has fully cured. Use clamps as needed.

Cutting stones accurately and efficiently is crucial for achieving a professional-looking result. If a wet saw is not available, alternative cutting methods may be necessary. A chisel and hammer can be used to cut smaller stones, but this method requires more patience and skill. Score the stone along the cut line using the chisel, then gently tap along the score line with the hammer until the stone breaks. Always wear safety glasses when using a chisel and hammer. For larger stones, consider renting a wet saw from a local tool rental store. Wet saws provide clean, precise cuts and minimize dust generation, making them the preferred method for cutting stone. Practice making cuts on scrap pieces of stone before cutting the actual facade material.

Maintaining consistent joint spacing is important for achieving a visually appealing facade. If joint spacing is inconsistent, the overall appearance of the facade can be compromised. Use spacers or pre-cut shims to maintain consistent joint spacing during the installation process. Adjust the placement of the stones as needed while the mortar is still pliable. If joints are too wide, fill them with additional mortar and retool them to create a uniform appearance. If joints are too narrow, carefully remove some of the mortar using a small chisel or screwdriver. Be careful not to damage the adjacent stones.

.jpg?strip=all)

Tips And Tools For Professional Stacked Stone Fireplaces

How To Build A Diy Stone Fireplace Boxwood Design Co

Thin Stone Veneers Make A Fireplace Update Easy Swenson Granite 100 Natural Stones

How To Install A Stone Veneer Fireplace Shoe Makes New

Stone Fireplace Makeover Taryn Whiteaker Designs

How To Build An Outdoor Stacked Stone Fireplace

How To Build And Hang A Mantel On Stone Fireplace Shanty 2 Chic

Diy Faux Plaster Fireplace Surround Chelsey Freng

Stone Fireplace Makeover Taryn Whiteaker Designs

Diy Faux Cast Stone Fireplace Part 2 Building The Mantel Top Shelf

Related Posts