Replacing A Gas Fireplace With A Wood Burning Insert: A Comprehensive Guide

Many homeowners with existing gas fireplaces eventually consider the option of converting them to a wood-burning insert. This shift can be driven by a variety of factors, including a desire for the ambiance and heat of a traditional wood fire, a preference for a more sustainable fuel source, or simply a dissatisfaction with the performance of the gas fireplace. Replacing a gas fireplace with a wood-burning insert is a significant project that requires careful planning, adherence to safety regulations, and often, professional installation. This article provides a comprehensive overview of the process, covering key considerations and essential steps.

A wood-burning fireplace insert is essentially a self-contained wood stove designed to fit inside an existing masonry or factory-built fireplace. Unlike open fireplaces, which are notoriously inefficient, wood-burning inserts are designed to burn wood more completely and efficiently, producing more heat with less fuel and fewer emissions. This improved efficiency translates to cost savings on heating bills and a reduced environmental impact.

Before embarking on this project, it is crucial to understand the scope of the work involved, the costs associated with it, and the potential benefits and drawbacks compared to maintaining a gas fireplace.

Assessing the Existing Fireplace and Chimney

The first and arguably most important step is to thoroughly assess the existing fireplace and chimney. An unsuitable fireplace or chimney can pose serious safety hazards. This assessment should be performed by a qualified chimney sweep or heating appliance professional. This professional can identify any structural issues, code violations, or other problems that need to be addressed before installing the wood-burning insert.

The assessment will involve a visual inspection of the firebox, smoke chamber, and chimney flue. The professional will look for cracks, spalling, or other signs of damage. The chimney flue must be sized correctly to accommodate the wood-burning insert. An undersized flue can lead to poor draft, smoke back-up into the house, and increased risk of chimney fires. An oversized flue can lead to rapid heat loss up the chimney, reducing the efficiency of the insert.

In many cases, the existing chimney flue will need to be lined with a new stainless steel liner specifically sized for the wood-burning insert. This is a crucial safety measure that protects the masonry chimney from the corrosive byproducts of wood combustion and ensures proper draft. The liner should extend from the insert connection all the way to the top of the chimney.

For factory-built fireplaces, the assessment is even more critical. Many factory-built fireplaces are not designed to accommodate wood-burning inserts. Attempting to install an insert in an incompatible fireplace can create a significant fire hazard. It is imperative to consult the fireplace manufacturer's specifications or a qualified professional to determine if the fireplace is suitable for an insert. If it is not, the entire fireplace unit may need to be replaced with a model specifically designed for wood-burning inserts.

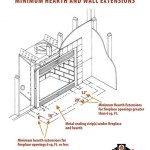

The hearth extension, the non-combustible surface in front of the fireplace opening, must also meet code requirements for wood-burning appliances. These requirements vary depending on the size and type of insert, but generally involve a certain distance of non-combustible material extending beyond the fireplace opening. If the existing hearth extension is insufficient, it will need to be enlarged.

Selecting the Right Wood-Burning Insert

Choosing the right wood-burning insert is essential for ensuring efficient heating, safe operation, and a visually appealing aesthetic. There are numerous models available on the market, each with different features, heating capacities, and efficiency ratings.

The first consideration is the heating capacity of the insert. This is typically measured in British Thermal Units (BTUs) per hour. The appropriate BTU rating will depend on the size of the area to be heated, the insulation levels of the house, and the climate. Consulting with a heating professional can help determine the optimal BTU rating for a specific application.

Efficiency is another critical factor. A more efficient insert will burn wood more completely, producing more heat with less fuel and fewer emissions. Look for inserts with high efficiency ratings, often expressed as a percentage. EPA-certified inserts are generally more efficient and produce fewer emissions than non-certified models.

The size and style of the insert should also be considered. The insert must fit properly into the existing fireplace opening. Take accurate measurements of the firebox dimensions to ensure a proper fit. The style of the insert should complement the existing décor of the room. Inserts are available in a variety of finishes and designs, from traditional to contemporary.

Other features to consider include the burn time, the size of the firebox, the presence of a blower fan, and the type of door. A longer burn time means less frequent refueling. A larger firebox allows for burning larger logs. A blower fan helps to circulate heat more effectively. The door can be either a single door or double doors, and can be made of cast iron or steel with a glass window.

It is also important to consider the type of wood that will be burned in the insert. Different types of wood have different heating values and burn characteristics. Hardwoods, such as oak and maple, generally produce more heat and burn longer than softwoods, such as pine and fir. Always burn seasoned (dried) wood to ensure efficient combustion and minimize creosote buildup in the chimney.

Installation Procedures and Safety Considerations

Installing a wood-burning insert is a complex and potentially dangerous task that should ideally be performed by a qualified professional. Incorrect installation can lead to serious safety hazards, including fires and carbon monoxide poisoning. However, some homeowners with sufficient experience and knowledge may choose to perform the installation themselves, provided they adhere to all applicable building codes and safety regulations.

Before beginning the installation, ensure that all necessary permits have been obtained from the local building department. These permits are typically required to ensure that the installation meets all applicable safety standards.

The first step in the installation process is to prepare the fireplace opening. This may involve cleaning the firebox, removing any debris, and repairing any damage to the masonry. The chimney flue must be thoroughly cleaned and inspected before installing the liner. As mentioned previously, installing a new stainless steel liner is typically required. The liner should be connected to the insert using a secure, airtight connection.

Once the liner is installed, the insert can be carefully slid into the fireplace opening. The insert should be securely positioned and leveled. Any gaps between the insert and the fireplace opening should be sealed with high-temperature sealant.

The final step is to connect the insert to the venting system. This typically involves connecting the insert to the chimney liner using a stove pipe connector. The connector should be securely fastened and sealed to prevent leaks. A carbon monoxide detector should be installed in the room where the insert is located to provide an early warning of any carbon monoxide leaks.

After the installation is complete, it is crucial to perform a test burn to ensure that the insert is operating properly and that there are no leaks or other problems. Monitor the draft to ensure that the smoke is being drawn up the chimney properly. Check for any signs of smoke back-up into the room. If any problems are detected, consult with a qualified professional to resolve them.

Regular maintenance is essential for ensuring the safe and efficient operation of the wood-burning insert. This includes regular chimney sweeping to remove creosote buildup, inspecting the liner for damage, and replacing any worn or damaged parts.

Replacing a gas fireplace with a wood-burning insert offers a host of benefits, including improved heating efficiency, a more traditional ambiance, and a potentially more sustainable fuel source. However, it is a significant undertaking that requires careful planning, professional expertise, and strict adherence to safety regulations. By understanding the key considerations and steps involved, homeowners can make an informed decision and ensure a safe and successful installation.

Converting A Wood Burning Fireplace Into Gas Heat Glo

Convert From Wood To Gas With A Insert The Kernel Burner

Can I Convert My Wood Burning Fireplace To Gas Woodlanddirect Com

Convert To Gas Installing Fireplace Inserts Doctor Flue

Want To Convert Gas Wood Fireplace Full Service Chimney

Should You Change Or Convert Your Wood Fireplace

Want To Convert Gas Wood Fireplace Full Service Chimney

Replacing A Gas Fireplace With Wood Burning Insert Chimney Sweeps Repairs And Installations

Replacing A Gas Fireplace With Real Wood Buringing One Hometalk

How To Install Gas Fireplace Insert Heat Glo