Refractory Panels for Wood Burning Fireplaces: A Comprehensive Guide

Refractory panels are a critical component of wood-burning fireplaces, serving as a protective barrier against intense heat and contributing significantly to the fireplace's overall efficiency and longevity. These panels are designed to withstand the extreme temperatures generated by burning wood, preserving the structural integrity of the fireplace and enhancing its performance. This article provides an in-depth examination of refractory panels, covering their composition, function, types, selection criteria, installation, maintenance, and troubleshooting.

Understanding the Function of Refractory Panels

The primary purpose of refractory panels is to protect the firebox of a wood-burning fireplace from the destructive effects of high temperatures. Fireboxes are typically constructed from materials like brick or concrete, which, while durable, are susceptible to cracking, spalling, and degradation when exposed to prolonged and intense heat. Refractory panels act as a sacrificial layer, absorbing and reflecting heat, thereby mitigating the thermal stress on the firebox structure. By insulating the firebox, these panels help to maintain a higher combustion temperature, leading to more efficient burning and reduced creosote buildup within the chimney.

Furthermore, refractory panels play a role in radiating heat into the room. The heat absorbed by the panels during the burning process is gradually released, contributing to the overall warmth and comfort of the space. This radiant heat is more efficient than convective heat, which relies on the circulation of air, as it directly warms objects and people in the room.

In summary, refractory panels serve a multifaceted purpose: protecting the firebox structure, enhancing combustion efficiency, and radiating heat into the room. Their presence is essential for the safe and effective operation of a wood-burning fireplace.

Types of Refractory Panels and Their Properties

Refractory panels are available in a variety of materials, each possessing unique properties that influence their performance and suitability for different fireplace applications. Common types of refractory panels include:

*Firebrick:

Firebrick is a traditional refractory material made from a blend of clay and other ceramic materials. It is known for its excellent heat resistance, thermal stability, and durability. Firebrick is typically dense and heavy, capable of withstanding prolonged exposure to high temperatures without significant degradation. However, it can be susceptible to thermal shock if rapidly heated or cooled. Firebrick is relatively inexpensive compared to other refractory materials, making it a popular choice for many fireplace installations. *Castable Refractory Cement:

This type of material is supplied as a dry powder which requires mixing with water to make a slurry. The mixture is then poured into a mold or applied to the firebox walls. After setting and curing, the resulting material forms a seamless, heat-resistant lining. Castable refractory cement offers good thermal resistance and can be shaped to fit complex firebox designs. It is often used to repair damaged fireboxes or to create custom refractory liners. *Refractory Concrete:

Similar to castable refractory cement, refractory concrete is a mixture of cement, aggregates, and other additives that is designed to withstand high temperatures. It is typically stronger and more durable than castable cement, making it suitable for applications where greater structural integrity is required. Refractory concrete is often used in industrial settings, but it can also be used in residential fireplaces. *Ceramic Fiber Boards:

These are lightweight panels made from ceramic fibers that are bonded together. They offer excellent insulation properties and are resistant to thermal shock. Ceramic fiber boards are easier to cut and install than firebrick, making them a popular choice for DIY projects. However, they are less durable than firebrick and may not be suitable for high-wear areas in the firebox. They are also more prone to physical damage from logs being tossed into the firebox. *Vermiculite Panels:

Vermiculite is a naturally occurring mineral that expands when heated. Vermiculite panels are lightweight and offer good insulation properties. They are often used in prefabricated fireplaces and stoves. Vermiculite panels are less durable than firebrick and are more susceptible to damage from impact.The selection of the appropriate type of refractory panel depends on several factors, including the design of the fireplace, the expected frequency of use, and the desired level of performance. Firebrick remains a popular choice for traditional fireplaces, while ceramic fiber boards and vermiculite panels are often used in prefabricated units. Castable refractory cements and refractory concretes are valuable for repairs and custom applications.

Selecting the Right Refractory Panels for Your Fireplace

Choosing the correct refractory panels is crucial for ensuring the safety, efficiency, and longevity of a wood-burning fireplace. The selection process should consider several key factors:

*Fireplace Type and Dimensions:

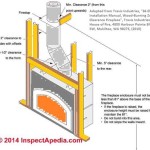

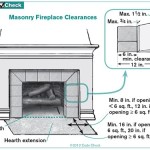

The type of fireplace – whether it is a traditional masonry fireplace or a prefabricated unit – will influence the type and size of refractory panels required. Masonry fireplaces typically use standard-sized firebrick, while prefabricated fireplaces often require specific panels that are designed to fit the firebox dimensions. Accurately measuring the firebox is essential for ensuring a proper fit and optimal performance. *Desired Performance:

Different refractory materials offer varying levels of heat resistance, insulation, and durability. Selecting a material that meets the specific performance requirements of the fireplace is crucial. For example, a fireplace that is used frequently and exposed to high temperatures will require a more durable material like firebrick or refractory concrete, while a fireplace that is used infrequently may be adequately protected by ceramic fiber boards. *Ease of Installation:

Some refractory materials are easier to install than others. Firebrick, for instance, requires mortar and careful placement, while ceramic fiber boards can be cut and fitted more easily. Consider the level of experience and available tools when selecting a material. For DIY installations, materials that are easier to work with may be preferred. *Cost:

Refractory materials vary in price, with firebrick generally being the most affordable option and specialized materials like refractory concrete being more expensive. It's important to balance the cost of the material with its performance characteristics and durability. Investing in high-quality refractory panels can save money in the long run by reducing the need for frequent repairs and replacements. *Building Codes and Regulations:

Local building codes and regulations may specify the types of refractory materials that are approved for use in fireplaces. It's essential to check with the local building department to ensure that the selected material complies with all applicable requirements.By carefully considering these factors, it is possible to select the right refractory panels for a wood-burning fireplace, ensuring its safe and efficient operation for years to come.

Installation and Maintenance of Refractory Panels

Proper installation and regular maintenance are essential for maximizing the lifespan and performance of refractory panels. The installation process will vary depending on the type of material being used, but some general guidelines apply.

When installing firebrick, it is crucial to use a refractory mortar that is specifically designed for high-temperature applications. The mortar should be mixed according to the manufacturer's instructions and applied evenly between the bricks to create a strong and heat-resistant bond. The bricks should be laid in a staggered pattern to increase the structural integrity of the firebox lining. Care should be taken to ensure that the bricks are properly aligned and that the mortar joints are flush with the surface.

When installing ceramic fiber boards or vermiculite panels, it is important to cut the panels to the correct size and shape using a utility knife or saw. The panels should be fitted snugly against the firebox walls without gaps or overlaps. Some panels may require the use of adhesive or fasteners to hold them in place. Ensure that the adhesive or fasteners are rated for high-temperature applications.

For castable refractory cement or refractory concrete, follow the manufacturer's instructions for mixing, pouring, and curing. Proper curing is essential for developing the material's full strength and heat resistance. This typically involves keeping the material moist for several days to prevent it from drying out too quickly.

Regular maintenance of refractory panels involves inspecting them periodically for cracks, spalling, or other signs of damage. Small cracks can often be repaired with refractory mortar, but more extensive damage may require replacing the affected panels. It is also important to clean the panels regularly to remove soot and creosote buildup. This can be done with a wire brush or scraper. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the panels.

Proper installation and regular maintenance will help to extend the lifespan of refractory panels and ensure that the wood-burning fireplace operates safely and efficiently.

Superior Wre4536 36 Fireplace White Stacked Refractory Panels Wr Fireplaces Usa

Hargrove 28 Inch Replacement Fireplace Refractory Panel Single Pack

Superior Vre4550 50 Fireplace White Herringbone Refractory Panels Fireplaces Usa

Hargrove 40 Inch Replacement Fireplace Refractory Panel Double Pack

Fireplace Refractory Panels Woodstoves Fireplaces

Superior Wrt3543 43 Fireplace Grey Herringbone Refractory Panels Fireplaces Usa

Superior 42 Traditional Vent Free Outdoor Firebox Vre4242 Us Fireplace

Superior 43 Wood Burning Fireplace Grey Herringbone Refractory Panels

Outdoor Wood Burning Fireplaces Superior 42 Fireplace Red Stacked Refractory Panels Wre3042rs

Wrt4536 36 Fireplace White Herringbone Refractory Panels Wrt4536wh Fire Pits Usa

Related Posts