Refractory Panels for Heatilator Fireplace: A Comprehensive Guide

Heatilator fireplaces are a popular choice for homeowners seeking an efficient and aesthetically pleasing heating solution. A key component within these fireplaces, significantly contributing to their performance and longevity, is the refractory panel. These panels, also known as firebox panels or firebrick, line the interior of the firebox and play a crucial role in reflecting heat, protecting the fireplace structure, and promoting efficient combustion. Understanding the function, materials, maintenance, and replacement of refractory panels is essential for Heatilator fireplace owners.

This article provides an in-depth exploration of refractory panels specifically designed for Heatilator fireplaces. It will cover the purpose of these panels, the materials used in their construction, common issues that may arise, how to identify when replacement is necessary, and a general overview of the replacement process. This information aims to equip homeowners with the knowledge needed to maintain their Heatilator fireplace and ensure its safe and efficient operation for years to come.

The Essential Role of Refractory Panels

The primary function of refractory panels is to withstand and reflect the intense heat generated within the fireplace firebox. This is critical for several reasons. Firstly, the panels protect the metal firebox walls from direct exposure to extreme temperatures, preventing warping, cracking, and premature deterioration. Without these panels, the lifespan of the fireplace would be significantly reduced.

Secondly, refractory panels contribute significantly to the fireplace’s heating efficiency. By reflecting heat back into the firebox, they help to maintain higher combustion temperatures. This leads to more complete burning of the wood, reducing creosote buildup in the chimney and maximizing the amount of heat radiated into the room. In essence, they act as a thermal barrier and reflector, improving the overall heating performance of the fireplace.

Thirdly, the panels often contribute to the aesthetic appeal of the fireplace. They are available in various textures, patterns, and colors, allowing homeowners to customize the look of their firebox. Some panels mimic the appearance of traditional brick, while others offer more contemporary designs. This allows for integration with various home decor styles.

Materials Used in Refractory Panel Construction

Refractory panels are typically manufactured from high-temperature resistant materials that can withstand the harsh conditions within a fireplace. Several materials are commonly used, each with its own properties and benefits. Understanding these materials can aid in selecting the appropriate replacement panels for a Heatilator fireplace.

One common material is fireclay brick, a type of ceramic material composed primarily of silica and alumina. Fireclay bricks are known for their excellent heat resistance and ability to withstand thermal shock, the rapid temperature changes that occur during fireplace use. They are relatively inexpensive and widely available, making them a popular choice for refractory panels.

Another material used is castable refractory cement. This material is often used to create custom-shaped panels or to repair existing panels. It consists of a mixture of refractory aggregates and hydraulic cement, which hardens when mixed with water. Castable refractory cement offers good heat resistance and can be molded to fit complex firebox designs.

Some manufacturers also use vermiculite-based panels. Vermiculite is a naturally occurring mineral that expands when heated, creating a lightweight and insulating material. Vermiculite panels offer excellent insulation properties, helping to retain heat within the firebox and improve heating efficiency. However, they may be more susceptible to physical damage than fireclay bricks.

The specific material used in refractory panels can vary depending on the Heatilator fireplace model and the manufacturer's design specifications. It's always best to consult the fireplace owner's manual or contact a qualified fireplace technician to determine the correct type of replacement panels.

Common Issues and Identifying the Need for Replacement

Despite their durability, refractory panels are subject to wear and tear over time due to the extreme temperatures and physical stresses they endure. Several common issues can arise, indicating that replacement may be necessary. Recognizing these issues early can prevent further damage to the fireplace and ensure safe operation.

Cracking is one of the most common problems affecting refractory panels. Small hairline cracks are generally not a cause for concern and may be a natural result of thermal expansion and contraction. However, large or expanding cracks can compromise the structural integrity of the panels and reduce their effectiveness in protecting the firebox. If cracks become wide enough to expose the metal firebox behind them, replacement is recommended.

Spalling, the flaking or crumbling of the surface of the panels, is another common issue. Spalling is often caused by moisture absorption and repeated freeze-thaw cycles, especially in fireplaces that are not properly maintained or protected from the elements. Spalling can weaken the panels and reduce their ability to reflect heat effectively.

Warping or distortion of the panels can also occur due to prolonged exposure to high temperatures. This can lead to gaps between the panels, allowing heat to escape and potentially damaging the firebox. Warped panels may also become unstable and pose a safety hazard.

Discoloration and soot buildup on the panels are normal occurrences, but excessive buildup can indicate poor combustion or a chimney obstruction. Addressing these issues can improve the fireplace's efficiency and reduce creosote accumulation.

Regular inspections of the refractory panels are crucial for identifying these issues early. Ideally, inspections should be performed before each heating season and periodically throughout the winter. Look for any signs of cracking, spalling, warping, or significant damage. If any of these issues are present, it is advisable to consult with a qualified fireplace technician to determine the appropriate course of action.

Refractory Panel Replacement: A General Overview

Replacing refractory panels is a task that many homeowners can undertake themselves, although professional assistance is recommended for those who are not comfortable with DIY projects or if the damage is extensive. Before starting the replacement process, it is essential to gather the necessary tools and materials. This typically includes the new refractory panels, a putty knife or scraper, a wire brush, safety glasses, gloves, and a dust mask.

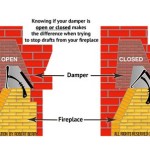

First, the fireplace should be completely cool before attempting any work. Remove any ash and debris from the firebox to provide a clean working surface. Carefully inspect the old panels to determine how they are installed. Some panels are held in place by clips, while others are simply fitted into place. Note the orientation and placement of the existing panels to ensure proper installation of the new ones.

Using a putty knife or scraper, gently loosen and remove the old panels. Be careful not to damage the firebox walls during this process. If the panels are heavily adhered, a hammer and chisel may be necessary, but use caution to avoid damaging the surrounding structure.

Once the old panels are removed, clean the firebox walls with a wire brush to remove any remaining debris or adhesive. Ensure that the surfaces are clean and dry before installing the new panels. Place the new panels into position, following the original orientation. If the panels are held in place by clips, ensure that they are securely fastened. If the panels are fitted into place, ensure they sit flush against the firebox walls.

After installing the new panels, allow any adhesive or sealant to cure completely before using the fireplace. Refer to the manufacturer's instructions for specific curing times. Once the curing process is complete, the fireplace is ready for use.

It is important to emphasize that this is a general overview of the replacement process. Specific instructions may vary depending on the Heatilator fireplace model and the type of refractory panels being used. Always consult the fireplace owner's manual or seek professional assistance for detailed instructions and safety precautions.

Selecting the Correct Replacement Panels

Choosing the correct replacement refractory panels for a Heatilator fireplace is paramount to ensure proper fit, performance, and safety. Several factors must be considered during the selection process. Using the wrong panels can compromise the fireplace’s efficiency, damage the firebox, and potentially create a fire hazard.

The first and most crucial step is to identify the correct part number for the replacement panels. This information can usually be found in the fireplace owner's manual or on a label affixed to the fireplace itself. If the part number is not readily available, contacting a Heatilator dealer or a qualified fireplace technician is advisable. They can help identify the correct panels based on the fireplace model number.

Once the part number is known, ensure that the replacement panels match the original specifications in terms of size, shape, and material. Using panels that are too large or too small can create gaps that allow heat to escape and potentially damage the firebox. Similarly, using panels made from a different material than the original can affect the fireplace’s heating efficiency and longevity.

Pay attention to the thickness of the replacement panels. Thicker panels generally offer better insulation and heat resistance, but they may not fit properly in the firebox if they are too thick. Ensure that the replacement panels are the same thickness as the original panels.

Consider the aesthetic appeal of the replacement panels. While functionality is the primary concern, the appearance of the panels can also contribute to the overall look of the fireplace. Choose panels that complement the existing decor and enhance the fireplace’s visual appeal. Many retailers offer a variety of textures and patterns to choose from.

Finally, purchase replacement panels from a reputable supplier. This ensures that the panels are of high quality and meet the manufacturer's specifications. Avoid purchasing panels from unknown or unreliable sources, as they may be substandard and compromise the safety and performance of the fireplace.

Heatilator Refractory Bottom Srv4010 018 Friendly Fires

Superior Wrt Wct 2042 42 Radiant Ws Refractory Panels Insulated F Fireplaces Usa

Heatilator Refractory Bottom Srv4010 018 Friendly Fires

Heatilator Back Refractory Panel 17179b

Heatilator Hb36a Refractory Bricks Post 25 92 17180a 17177b 17174b

Replacing Refractory Panels

How To Replace The Firebrick On A Heatilator Fireplace Ehow

Heatilator Icon Series Wood Fireplace Fireside Hearth And Leisure

Heatilator Heirloom 42 Traditional Direct Vent Natural Gas Fireplace Us

Outdoor Lifestyle Cottagewood 42 Wood Burning Fireplace Wit Fireplaces Usa

Related Posts