Radiant Heat Fireplace Inserts: An In-Depth Exploration

Fireplace inserts offer a way to enhance the efficiency and convenience of existing fireplaces. Among the various types available, radiant heat fireplace inserts stand out for their ability to directly warm objects and individuals within a room, creating a comfortable and energy-efficient heating solution. This article delves into the details of radiant heat fireplace inserts, exploring their mechanics, benefits, types, installation considerations, and maintenance aspects.

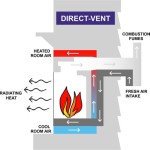

Radiant heat, as the name suggests, is a form of energy transfer that relies on electromagnetic waves. Unlike convection, which heats the air that then circulates, radiant heat directly warms surfaces it encounters. This means that objects and people in the path of the radiant heat emitted from the insert will feel warmer, even if the surrounding air temperature remains relatively constant. This direct heating effect is a key advantage of radiant heat fireplace inserts.

Understanding the Mechanics of Radiant Heat Fireplace Inserts

A radiant heat fireplace insert functions by generating heat through the combustion of fuel, typically wood, gas, or pellets. The generated heat warms the insert's firebox and the surrounding metal components. These heated surfaces then radiate energy outward in the form of infrared radiation. This radiation travels through the air and is absorbed by objects and individuals in the room, raising their temperature. The efficiency of a radiant heat fireplace insert is determined by its ability to maximize heat radiation and minimize heat loss through the chimney or other pathways.

The design of the insert plays a significant role in its radiant heat output. Inserts with large, exposed surface areas, particularly those constructed from materials with high thermal conductivity like cast iron or steel, tend to radiate heat more effectively. The presence of glass doors, either single or double-pane, also contributes to radiant heat transfer. However, the quality of the glass and the design of the door frame can significantly impact the amount of heat radiated.

Furthermore, the type of fuel used influences the heat output. Wood-burning inserts, for example, generally produce a higher BTU (British Thermal Unit) output compared to gas or pellet inserts, resulting in greater radiant heat production. However, wood-burning inserts also require more maintenance and careful management of the fire to ensure efficient and clean burning.

Advantages of Radiant Heat Fireplace Inserts

Radiant heat fireplace inserts offer numerous advantages over traditional open fireplaces and other heating methods. These benefits stem from their efficiency, comfort, and convenience.

One of the primary advantages is energy efficiency. By directing heat into the room through radiation, these inserts minimize heat loss up the chimney, a common problem with traditional fireplaces. This improved efficiency can lead to significant energy savings, reducing heating costs and lowering the reliance on central heating systems.

Another key benefit is the enhanced comfort they provide. The direct warming effect of radiant heat eliminates cold spots and creates a more consistent and comfortable room temperature. Unlike convection heating, which can cause drafts and uneven heating, radiant heat provides a gentle and even warmth that is particularly appreciated during colder months.

Convenience is also a significant factor. Gas and pellet inserts offer push-button ignition and thermostatic control, eliminating the need to manually tend to the fire. This makes them a convenient and user-friendly option for homeowners seeking a hassle-free heating solution. While wood-burning inserts require more manual effort, they still offer a significant improvement over open fireplaces in terms of control and efficiency.

Finally, radiant heat fireplace inserts can improve indoor air quality. By burning fuel more efficiently and controlling the combustion process, these inserts reduce the emission of pollutants into the home compared to open fireplaces. Many inserts are designed to meet stringent EPA (Environmental Protection Agency) emission standards, ensuring cleaner and healthier indoor air.

Types of Radiant Heat Fireplace Inserts

Radiant heat fireplace inserts are available in various fuel types, each with its own characteristics and advantages. The most common types include wood-burning, gas, and pellet inserts.

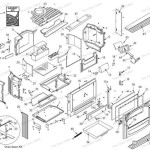

Wood-burning inserts are the traditional choice, offering the ambiance and warmth of a wood fire. These inserts typically have a cast iron or steel firebox and a glass door to contain the fire and radiate heat. Wood-burning inserts require a readily available source of seasoned wood and regular maintenance, including ash removal and chimney cleaning.

Gas inserts provide a convenient and clean-burning alternative to wood. These inserts operate on natural gas or propane and offer push-button ignition and thermostatic control. Gas inserts are generally easier to maintain than wood-burning inserts and produce fewer emissions. They are a popular choice for homeowners seeking a hassle-free heating solution with the visual appeal of a fireplace.

Pellet inserts utilize compressed wood pellets as fuel. Pellets are a renewable and relatively clean-burning fuel source. Pellet inserts typically have a hopper that feeds pellets into the firebox automatically, providing consistent and controlled heat output. These inserts often feature advanced controls and sensors to optimize combustion efficiency and minimize emissions. Pellets do require storage space and the units need to be cleaned periodically of ash and combustion byproducts.

Each type of insert has advantages and disadvantages regarding cost, efficiency, maintenance, and environmental impact. Factors such as fuel availability, personal preferences, and local regulations should be considered when selecting the appropriate type of radiant heat fireplace insert.

Installation Considerations

The installation of a radiant heat fireplace insert is a critical process that should be performed by a qualified professional. Proper installation ensures the safe and efficient operation of the insert and prevents potential hazards such as carbon monoxide poisoning or chimney fires.

Before installation, the existing fireplace and chimney must be inspected to ensure they are structurally sound and compatible with the chosen insert. The chimney should be cleaned and inspected for any cracks or damage that could compromise its integrity. In some cases, the chimney may need to be relined or repaired to meet safety standards.

The size of the insert should be carefully matched to the size of the fireplace opening and the heating needs of the room. An undersized insert may not provide sufficient heat, while an oversized insert can lead to overheating and inefficient operation.

Proper ventilation is essential for safe and efficient combustion. The insert should be connected to the chimney with a properly sized flue liner. The liner prevents exhaust gases from leaking into the home and ensures proper draft for the insert. The installation of a carbon monoxide detector is also highly recommended to provide an additional layer of safety.

Local building codes and regulations regarding fireplace inserts should be followed closely during installation. Permits may be required, and inspections may be necessary to ensure compliance with safety standards. Engaging a certified installer who is familiar with local regulations is crucial for a successful and safe installation.

Maintenance of Radiant Heat Fireplace Inserts

Regular maintenance is essential for maintaining the efficiency and extending the lifespan of a radiant heat fireplace insert. The specific maintenance requirements vary depending on the type of insert and the frequency of use.

For wood-burning inserts, regular ash removal is necessary to prevent ash buildup in the firebox. The chimney should be inspected and cleaned annually by a qualified chimney sweep to remove creosote, a flammable byproduct of wood combustion. Creosote buildup can increase the risk of chimney fires.

Gas inserts require less frequent maintenance than wood-burning inserts. The burner should be inspected and cleaned periodically to ensure proper combustion. The glass door should be cleaned with a non-abrasive cleaner to remove soot and residue. A qualified technician should inspect the gas connections and control system annually.

Pellet inserts also require regular maintenance, including hopper cleaning, ash removal, and venting system cleaning. The igniter and auger should be inspected and cleaned periodically to ensure proper operation. A qualified technician should inspect the insert annually to ensure it is functioning correctly and safely.

Regardless of the type of insert, it is important to follow the manufacturer's instructions for maintenance and cleaning. Regular maintenance not only ensures the efficient and safe operation of the insert but also helps to prevent costly repairs and extend its lifespan.

Radiant Plus Fireplace Inserts Made In Usa Lopi Stoves

Understanding Radiant Heat Valor Gas Fireplaces

Lopi Radiant Plus Medium Gas Fireplace Insert Fireside Hearth And Leisure

Radiant Or Convection Heat Here S What You Should Know

Lopi Radiant Plus Small Gas Fireplace Insert Quality Stoves Spas

Radiant Plus Fireplace Inserts Made In Usa Lopi Stoves

Lopi Radiant Plus Large Gas Fireplace Insert Gallery Of Western Michigan

Lopi Radiant Plus Medium Gas Fireplace Insert Fireside Hearth And Leisure

Radiant Or Convection Heat Here S What You Should Know

Cast Iron Wood Fireplace Insert Flame Connection

Related Posts