Understanding Quikrete Fireplace Mortar Cement Caulk: Applications and Best Practices

Quikrete Fireplace Mortar Cement Caulk is a specialized product designed for repairing and sealing joints and cracks in fireplace and chimney applications. This cement caulk offers a robust solution for addressing issues related to heat exposure and weathering, common challenges in fireplace structures. It is formulated to withstand high temperatures and provide a durable, weather-resistant seal, extending the lifespan of fireplace components and improving their overall functionality.

This article delves into the characteristics of Quikrete Fireplace Mortar Cement Caulk, its various applications, and best practices for its successful implementation. Understanding these aspects is crucial for homeowners and professionals alike who are aiming to maintain and repair fireplace systems effectively.

Key Features of Quikrete Fireplace Mortar Cement Caulk

Several key features distinguish Quikrete Fireplace Mortar Cement Caulk from standard caulks and mortars. These properties contribute to its suitability for demanding fireplace and chimney environments:

Firstly, heat resistance is a primary advantage. The caulk is formulated to withstand high temperatures encountered within fireplaces without cracking, crumbling, or losing adhesion. This heat resistance is essential for maintaining the integrity of the seal and preventing smoke or gas leakage.

Secondly, weather resistance is another critical attribute. Fireplaces and chimneys are constantly exposed to the elements, including rain, snow, and fluctuating temperatures. Quikrete Fireplace Mortar Cement Caulk is designed to resist degradation from these environmental factors, ensuring long-lasting protection against water damage and erosion.

Thirdly, adhesion strength is paramount for a successful application. The caulk adheres strongly to various masonry surfaces, including brick, stone, and concrete. This strong adhesion prevents the caulk from detaching or peeling away, even under thermal stress and physical abrasion.

Fourthly, flexibility is also an important consideration. While it's cement-based, the caulk possesses a degree of flexibility that allows it to accommodate minor movements and expansions/contractions in the fireplace structure without cracking. This flexibility helps maintain the seal over time.

Finally, ease of application contributes to its popularity. Quikrete Fireplace Mortar Cement Caulk is typically available in tubes that can be applied using a standard caulking gun, making it easy for both professionals and DIY enthusiasts to use. The smooth consistency allows for easy tooling and a neat, professional finish.

Applications of Quikrete Fireplace Mortar Cement Caulk

The versatile nature of Quikrete Fireplace Mortar Cement Caulk makes it suitable for a wide range of applications in and around fireplaces and chimneys. These applications include:

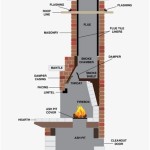

Sealing cracks and joints in fireboxes is a common use. Fireboxes are subject to intense heat, which can cause mortar joints to crack over time. This caulk effectively seals these cracks, preventing smoke and carbon monoxide from escaping into the home. The caulk's heat resistance ensures that the seal remains intact even under extreme temperatures.

Repairing mortar joints in chimneys is another frequent application. Chimneys are exposed to weathering and temperature fluctuations, leading to mortar deterioration. The caulk can be used to fill gaps and repair damaged mortar joints, preventing water penetration and structural damage. This repair work helps maintain the chimney's integrity and prevents costly repairs later on.

Sealing around flue liners also benefits from this product. Flue liners are crucial for safely venting combustion gases from the fireplace. The caulk can be used to seal the gap between the flue liner and the chimney structure, preventing leaks and ensuring proper ventilation. This application improves fireplace safety and efficiency.

Patching damaged firebricks is another practical use. Firebricks are designed to withstand high temperatures but can still crack or chip over time. While not a replacement for a complete brick, the caulk can be used to patch small cracks and chips, extending the life of the firebricks and preventing further damage. This patching helps maintain the firebox's integrity and performance.

Waterproofing chimney crowns can be achieved through the use of this product. Chimney crowns are the top portion of the chimney and are particularly vulnerable to water damage. The caulk can be applied to seal cracks and prevent water from entering the chimney structure, thus avoiding freeze-thaw damage and other related issues. This waterproofing extends the life of the chimney and prevents costly repairs.

Best Practices for Using Quikrete Fireplace Mortar Cement Caulk

To ensure a successful and long-lasting application of Quikrete Fireplace Mortar Cement Caulk, it is important to follow best practices for preparation, application, and curing. These include:

Proper surface preparation is crucial. Before applying the caulk, the surfaces must be clean, dry, and free of loose debris, dirt, and old caulk. Use a wire brush or scraper to remove any loose material and then wipe the surface with a damp cloth to remove any remaining dust. A clean surface ensures optimal adhesion of the caulk.

Choosing the correct caulk gun is also important. A high-quality caulk gun will provide a smooth and consistent flow of caulk, making it easier to apply the material evenly. Choose a gun with a comfortable grip and a reliable trigger mechanism. A smooth, consistent application is essential for a professional-looking and effective seal.

Applying the caulk evenly is essential. Cut the nozzle of the caulk tube at a 45-degree angle and apply the caulk in a continuous bead along the joint or crack. Maintain a consistent pressure on the caulk gun to ensure a uniform flow of material. An even application ensures that the entire joint or crack is properly sealed.

Tooling the caulk is a necessary step. After applying the caulk, use a tool such as a putty knife or a wet sponge to smooth the bead and press it firmly into the joint. This tooling process ensures that the caulk adheres properly to the surfaces and creates a watertight seal. Tooling also creates a neat and professional-looking finish.

Allowing for proper curing time is paramount. Quikrete Fireplace Mortar Cement Caulk requires sufficient time to cure properly. Follow the manufacturer's instructions for curing time, typically 24 to 72 hours. Protect the applied caulk from moisture and extreme temperatures during the curing process. Proper curing ensures that the caulk develops its full strength and durability.

Choosing the right weather conditions aids in the application. Avoid applying the caulk in extremely hot or cold weather. Ideal application temperatures are typically between 40°F and 90°F. Extreme temperatures can affect the caulk's adhesion and curing properties. Applying in suitable weather conditions ensures optimal performance.

Considering safety precautions are essential. When working with Quikrete Fireplace Mortar Cement Caulk, wear appropriate safety gear, including gloves and eye protection. Avoid contact with skin and eyes. If contact occurs, rinse thoroughly with water. Safety precautions protect against potential irritation or allergic reactions.

Storing the caulk properly helps maintain its integrity. Store unused caulk tubes in a cool, dry place. Ensure that the nozzle is tightly sealed to prevent the caulk from drying out. Proper storage extends the shelf life of the caulk and ensures that it remains usable for future projects.

Regular inspection of the areas where the caulk has been applied is a good practice. Periodically inspect the applied caulk for cracks, deterioration, or loss of adhesion. Address any issues promptly to prevent further damage. Regular maintenance ensures the continued effectiveness of the seal and protects the fireplace and chimney from water damage and other issues.

It's important to note that while Quikrete Fireplace Mortar Cement Caulk is a versatile product, it is not designed for every type of repair. For significant structural damage or large-scale repairs, consulting a professional mason or chimney expert is highly recommended. They can assess the situation and provide appropriate solutions to ensure the safety and integrity of the fireplace and chimney.

By understanding the features, applications, and best practices associated with Quikrete Fireplace Mortar Cement Caulk, homeowners and professionals can make informed decisions about its use in maintaining and repairing fireplaces and chimneys. A proactive approach to fireplace maintenance can help prevent costly repairs and ensure the safe and efficient operation of these important home features.

Dap 10 1 Oz Gray Concrete And Mortar Filler Latex Sealant 18096 The Home Depot

Quikrete 10 Oz Fireplace Repair Mortar 862024 The Home Depot

Quikrete Cos Fireplace Mortar Concrete Construction

Reviews For Quikrete 10 Oz Mortar Repair Sealant Pg 1 The Home Depot

Watch Fireplace Mortar

Reviews For Quikrete 10 Oz Mortar Repair Sealant Pg 1 The Home Depot

Quikrete Fireplace Mortar Helps Enhance Home

Reviews For Quikrete 10 Oz Mortar Repair Sealant Pg 1 The Home Depot

Mortar Repair 1 Hour Easy Tuckpointing Repointing Caulk Stops Water

How To Fix Ed Mortar Or Concrete In A Fireplace With Mor Flexx