Precast Fireplace Kits: A Comprehensive Overview

Precast fireplace kits offer a convenient and often cost-effective alternative to traditional, site-built fireplaces. These kits consist of prefabricated components, typically made from concrete or a similar fire-resistant material, designed to be assembled on-site. The result is a fully functional fireplace that resembles a custom-built structure but requires significantly less labor and specialized expertise.

The use of precast technology in fireplace construction has gained considerable traction in recent years due to several factors, including the consistency of manufacturing, the speed of installation, and the wide range of design options available. While traditional masonry fireplaces require skilled bricklayers and a prolonged construction timeline, precast kits streamline the process, making them an attractive option for both homeowners and builders.

This article will explore the various aspects of precast fireplace kits, including their advantages, disadvantages, material composition, installation procedures, design considerations, and maintenance requirements. Understanding these elements is crucial for making informed decisions about incorporating a precast fireplace into a residential or commercial setting.

Advantages of Precast Fireplace Kits

One of the primary advantages of precast fireplace kits is the reduced installation time compared to traditional masonry fireplaces. The prefabricated components are manufactured in a controlled environment, ensuring consistent dimensions and quality. This precision allows for faster assembly on-site, minimizing labor costs and project delays. A typical precast fireplace installation can often be completed in a matter of days, whereas a masonry build could take weeks.

Another significant benefit is cost-effectiveness. While the initial cost of a precast kit might be comparable to the materials required for a masonry fireplace, the reduction in labor costs significantly lowers the overall project expense. The prefabricated nature of the components also minimizes material waste, further contributing to cost savings.

Precast fireplace kits offer a wide range of design options. Manufacturers produce kits in various styles, from traditional to contemporary, allowing homeowners and builders to select a design that complements the architectural style of the building. These kits can also be customized with different finishes, such as stone veneers or decorative moldings, to create a unique aesthetic.

Furthermore, precast components are typically manufactured with strict quality control measures. This ensures consistent performance and durability, reducing the likelihood of structural issues or premature wear and tear. The use of fire-resistant materials in the manufacturing process also enhances safety and provides peace of mind.

Finally, the relative simplicity of installation, while often requiring a professional or experienced individual, reduces the need for highly specialized masons, expanding the pool of available installers.

Disadvantages of Precast Fireplace Kits

While precast fireplace kits offer numerous advantages, there are also potential drawbacks to consider. One common concern is the limited customization options compared to a fully custom-built masonry fireplace. While manufacturers offer a variety of designs and finishes, the overall structure of the fireplace is predetermined by the kit components.

Another potential issue is the aesthetic appeal. While precast fireplaces can be designed to resemble traditional masonry structures, some individuals may perceive them as lacking the authenticity and character of a custom-built fireplace. The visible seams between the precast components can also be a point of contention for some homeowners.

Transportation and handling of the precast components can also pose challenges. The components are often heavy and bulky, requiring specialized equipment for lifting and maneuvering. This can add to the overall project cost and complexity, particularly in situations where access to the installation site is limited.

Additionally, repairs to precast fireplaces can sometimes be more challenging than repairs to masonry fireplaces. If a component is damaged, it may be necessary to replace the entire section, rather than simply repairing the affected area. This can be more costly and time-consuming.

Finally, the resale value of a home with a precast fireplace may not be as high as a home with a custom-built masonry fireplace, although this is highly dependent on regional preferences and the overall quality and design of the installation.

Material Composition and Construction

Precast fireplace kits are typically constructed from a blend of concrete, aggregates, and reinforcing materials. The specific composition of the materials can vary depending on the manufacturer and the intended application, but the primary goal is to create a fire-resistant and durable structure.

The concrete used in precast fireplace components is often a high-strength mix designed to withstand the high temperatures generated by a fire. The aggregates, such as sand and gravel, contribute to the overall strength and stability of the concrete. Reinforcing materials, such as steel rebar or wire mesh, are embedded within the concrete to enhance its tensile strength and prevent cracking.

The manufacturing process typically involves pouring the concrete mixture into molds that are shaped to the desired dimensions and design. The molds are then vibrated to remove air pockets and ensure a dense, uniform structure. The components are cured under controlled conditions to achieve optimal strength and durability.

Once the components are cured, they are inspected for any defects or inconsistencies. The components are then packaged and shipped to the installation site. The kit typically includes all of the necessary components for assembling the fireplace, including the firebox, smoke chamber, chimney flue, and surround.

The firebox, which is the area where the fire is built, is often lined with firebrick to provide additional protection against the high temperatures. The smoke chamber is designed to collect and channel the smoke up the chimney flue. The chimney flue is a vertical duct that carries the smoke and combustion gases away from the building.

The exterior surround of the fireplace can be finished with a variety of materials, such as stone veneer, brick, tile, or stucco. This allows homeowners and builders to customize the appearance of the fireplace to match their aesthetic preferences.

Installation Procedures

The installation of a precast fireplace kit typically involves several steps, including site preparation, component assembly, and finishing. While the specific procedures may vary depending on the kit manufacturer and the design of the fireplace, the general principles remain the same.

The first step is to prepare the site by ensuring that the foundation is level and capable of supporting the weight of the fireplace. A concrete pad is typically required to provide a stable base for the structure. The location of the fireplace should also be chosen carefully to ensure proper ventilation and fire safety.

Once the site is prepared, the components can be assembled according to the manufacturer's instructions. This typically involves mortaring the components together and securing them with fasteners. It is important to follow the instructions carefully to ensure a structurally sound and properly functioning fireplace.

The firebox is usually assembled first, followed by the smoke chamber and chimney flue. The components should be aligned carefully to ensure a proper draft and prevent smoke from escaping into the room. The chimney flue should extend above the roofline to provide adequate ventilation.

After the structural components are assembled, the exterior surround can be installed. This may involve applying a mortar bed and attaching stone veneer, brick, tile, or stucco. The surround should be carefully integrated with the surrounding wall surfaces to create a seamless and aesthetically pleasing appearance.

Finally, the fireplace should be inspected by a qualified professional to ensure that it meets all applicable building codes and safety regulations. The inspection should include a smoke test to verify that the chimney flue is functioning properly and that there are no leaks or obstructions.

It is generally recommended to hire a professional installer for a precast fireplace kit to ensure the job is done correctly and safely. Improper installation can lead to structural problems, fire hazards, and other issues.

Design Considerations

When selecting a precast fireplace kit, there are several design considerations to keep in mind. The first is the overall style of the fireplace. Manufacturers offer a wide range of designs, from traditional to contemporary, so it is important to choose a style that complements the architectural style of the building.

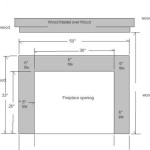

Another important consideration is the size of the fireplace. The fireplace should be appropriately sized for the room in which it will be installed. A fireplace that is too small may not provide adequate heat, while a fireplace that is too large can overwhelm the space.

The type of fuel to be used in the fireplace should also be considered. Some precast fireplace kits are designed for wood-burning, while others are designed for gas or electric inserts. It is important to choose a kit that is compatible with the desired fuel type.

The location of the fireplace should also be carefully considered. The fireplace should be located in a place where it will provide adequate heat and ambiance without obstructing traffic flow or creating a fire hazard. It is also important to ensure that the fireplace is properly ventilated and that the chimney flue extends above the roofline.

The finish of the fireplace should also be chosen carefully. The finish should complement the surrounding decor and create a visually appealing focal point. There are many different finishes to choose from, including stone veneer, brick, tile, and stucco.

Finally, it is important to consider the cost of the fireplace kit and the installation. Precast fireplace kits can range in price from a few hundred dollars to several thousand dollars, depending on the size, style, and features. The installation costs can also vary depending on the complexity of the project and the location of the installation site.

Maintenance Requirements

Like any fireplace, precast fireplaces require regular maintenance to ensure optimal performance and safety. The specific maintenance requirements may vary depending on the type of fuel used and the design of the fireplace, but the general principles remain the same.

One of the most important maintenance tasks is to clean the chimney flue regularly. The chimney flue can become clogged with creosote, a flammable substance that can pose a fire hazard. The National Fire Protection Association (NFPA) recommends that chimneys be inspected and cleaned at least once a year by a qualified professional.

The firebox should also be cleaned regularly to remove ashes and debris. Ashes can accumulate quickly and can reduce the efficiency of the fireplace. The firebox should be cleaned after each use or at least once a week during the heating season.

The exterior surround of the fireplace should also be cleaned regularly to remove dust and grime. The specific cleaning methods will vary depending on the type of finish. Stone veneer and brick can be cleaned with a mild detergent and water, while tile and stucco may require more specialized cleaning products.

Any cracks or damage to the precast components should be repaired promptly to prevent further deterioration. Small cracks can be filled with mortar or sealant, while larger cracks may require more extensive repairs. If a component is severely damaged, it may need to be replaced.

The damper, which controls the airflow in the chimney flue, should also be inspected regularly to ensure that it is functioning properly. A malfunctioning damper can reduce the efficiency of the fireplace and can also allow smoke to escape into the room.

Finally, it is important to have the fireplace inspected regularly by a qualified professional to ensure that it is functioning safely and efficiently. The inspection should include a smoke test to verify that the chimney flue is venting properly and that there are no leaks or obstructions.

Outdoor Fireplaces

Precast Outdoor Fireplaces Concretenetwork Com

Outdoor Fireplaces

Farm Show The Best Stories About Made It Myself Inventions Farming And Gardening Tips Time Saving Tricks S Diy Projects On Boosting Your Income

Outdoor Fireplace Kits 36 And 42

Masonry Fireplace Kits Prefabricated Fireplaces Masonlite Sandkuhl

Diy Outdoor Fireplaces Wood Burning Fireplace Kits

Outdoor Fireplaces Diy Kits Plans Cape Cod Ma Ri

Diy Outdoor Fireplaces Wood Burning Fireplace Kits

Outdoor Fireplace Kits Masonry Stone

Related Posts