Pellet Stove Fireplace Insert Venting: A Comprehensive Guide

Pellet stove fireplace inserts offer an efficient and aesthetically pleasing heating solution for homes. Converting an existing masonry fireplace into a pellet-burning appliance requires careful consideration of venting requirements. The venting system plays a crucial role in expelling combustion byproducts safely and efficiently, ensuring optimal performance and preventing potential hazards. This article provides a comprehensive overview of pellet stove fireplace insert venting, covering key aspects such as venting types, installation considerations, maintenance, and safety precautions.

A properly installed and maintained venting system is paramount for the safe and efficient operation of a pellet stove fireplace insert. Improper venting can lead to a range of problems, including poor combustion, smoke spillage, carbon monoxide poisoning, and chimney fires. Therefore, understanding the different venting options and adhering to manufacturer's instructions and local building codes is essential.

Understanding Venting Types for Pellet Stove Fireplace Inserts

Various venting systems are available for pellet stove fireplace inserts, each with specific characteristics and suitability for different installation scenarios. The most common types include: Direct Vent, Chimney Liner Venting, and occasionally, through-the-wall venting. The choice of venting system depends on factors such as the existing chimney structure, the stove's specifications, and local building codes.

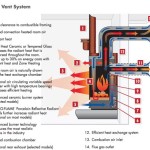

Direct Vent Systems: Direct vent systems, also known as concentric venting, draw combustion air from the outside and exhaust flue gases through a single vent pipe. This type of venting ensures complete isolation of the combustion process from the indoor environment. The system consists of two concentric pipes, with the inner pipe exhausting flue gases and the outer pipe drawing in fresh air. Direct vent systems are typically used when there is no existing chimney or when the existing chimney is unsuitable for pellet stove venting.

Direct vent systems offer several advantages, including enhanced safety and efficiency. The sealed combustion process minimizes the risk of backdrafting and carbon monoxide poisoning. Furthermore, the preheated combustion air improves fuel efficiency and reduces emissions. Installation typically involves running the vent pipe horizontally through an exterior wall.

Chimney Liner Venting: Chimney liner venting involves installing a stainless steel liner inside an existing masonry chimney. This is the most common method when a homeowner wants to utilize an existing chimney for the pellet stove insert. The liner provides a dedicated pathway for the exhaust gases, protecting the chimney structure from corrosion and ensuring proper draft. The liner must be appropriately sized to match the appliance's venting requirements. It is typically a flexible or rigid stainless steel pipe that is inserted into the chimney flue.

Chimney liner venting is generally more cost-effective than building a new chimney or using a direct vent system. However, it requires that the existing chimney be in good condition and able to support the liner. A thorough inspection of the chimney is crucial to identify any structural damages or obstructions that could compromise the venting system's performance. If the chimney exhibits signs of deterioration, repairs may be necessary before installing the liner.

Through-the-Wall Venting: Though less common, through-the-wall venting is an option in certain situations where a chimney is not available and direct venting is impractical. This method involves running the vent pipe directly through an exterior wall. However, through-the-wall venting must comply with strict safety regulations regarding clearance to combustibles and proximity to windows and doors. Generally, it is recommended the vent is at least one foot above the ground. It is crucial to consult local building codes and manufacturer's instructions before considering through-the-wall venting.

The specific requirements for through-the-wall venting vary depending on the stove model and local regulations. Typically, a specialized vent pipe with a heat shield is required to protect the wall from excessive heat. Furthermore, a termination cap must be installed to prevent rainwater and debris from entering the vent pipe.

Essential Installation Considerations

Proper installation of the pellet stove fireplace insert venting system is crucial for ensuring safe and efficient operation. This involves following manufacturer's instructions, complying with local building codes, and using appropriate materials. It is highly recommended to hire a certified professional to install the venting system to ensure proper installation and avoid potential hazards.

Vent Pipe Material: Pellet stoves typically require the use of special "PL" vent piping designed for pellet stoves. This pipe is designed to withstand the corrosive effects of the flue gases produced by pellet combustion. The PL vent piping is typically made of stainless steel and has a double-wall construction with insulation to prevent condensation and heat loss. Using the correct type of vent pipe is essential for safety and longevity.

Vent Pipe Size and Length: The vent pipe's diameter and length must be precisely matched to the stove's specifications. Undersized or excessively long vent pipes can restrict airflow, leading to poor combustion and increased creosote buildup. Oversized vent pipes can also cause problems, such as excessive draft and reduced efficiency. Consult the manufacturer's instructions for the recommended vent pipe size and length for your specific stove model.

Clearances to Combustibles: Maintaining proper clearances to combustible materials is crucial for preventing fires. The vent pipe must be installed at a safe distance from walls, ceilings, and other flammable materials. The manufacturer's instructions typically specify the required clearances. Heat shields may be necessary to reduce clearances in certain situations.

Sealing and Connections: All vent pipe connections must be properly sealed to prevent leaks. Use high-temperature silicone sealant to ensure airtight joints. Leaks can lead to smoke spillage, carbon monoxide poisoning, and reduced efficiency. Inspect all connections regularly to ensure they remain sealed.

Draft Considerations: Adequate draft is vital for proper venting. Draft refers to the flow of air through the venting system. Insufficient draft can cause smoke to back up into the room. Factors that can affect draft include the height of the chimney, the vent pipe's diameter, and the presence of obstructions. A barometric damper may be installed to regulate the draft and ensure consistent performance.

Maintenance and Safety Precautions

Regular maintenance of the pellet stove fireplace insert venting system is crucial for maintaining optimal performance and preventing potential hazards. This includes inspecting and cleaning the vent pipe, checking for leaks, and ensuring proper draft. Following safety precautions when operating and maintaining the stove is also essential.

Vent Pipe Cleaning: The vent pipe should be cleaned regularly to remove creosote and ash buildup. Creosote is a highly flammable substance that can accumulate inside the vent pipe, increasing the risk of chimney fires. The frequency of cleaning depends on the stove's usage and the type of fuel burned. As a general guideline, the vent pipe should be inspected at least annually and cleaned as needed. You can find brushes and rods designed for cleaning pellet stove venting systems at most home improvement stores.

Inspecting for Leaks: Regularly inspect the vent pipe connections for leaks. Use a smoke stick or a flashlight to check for any signs of smoke escaping from the joints. Address any leaks promptly to prevent smoke spillage and carbon monoxide poisoning. Replace any damaged or corroded vent pipe sections.

Carbon Monoxide Detectors: Install carbon monoxide detectors in your home, particularly near sleeping areas. Carbon monoxide is a colorless, odorless gas that can be deadly. Test the detectors regularly to ensure they are functioning properly. If the alarm sounds, evacuate the premises immediately and call emergency services.

Professional Inspections: Schedule regular professional inspections of your pellet stove fireplace insert and venting system. A certified technician can identify potential problems that may not be apparent during routine maintenance. Professional inspections can help ensure the safe and efficient operation of your stove.

Fuel Quality: Use only high-quality pellets that are specifically designed for pellet stoves. Low-quality pellets can produce more ash and creosote, increasing the frequency of cleaning and maintenance. Store pellets in a dry place to prevent them from absorbing moisture, which can affect their burning efficiency. Additionally, it's important to keep flammable material away from the area to avoid potential fire hazards.

How To Install A Pellet Vent Pipe

Chimney Liners Usa Fireplace Insert Venting Information

Enhance Your Fireplace With Pellet Inserts In Dc

Gas Fireplace Venting Explained Heat Glo

Pellet Burning Fireplace Inserts Sierra Hearth And Home

Why Choose An Insert Made In Usa Lopi Stoves

Chimney Flue Exhaust Kit Fireplace Insert For Corn Or Wood Pellet

Fireplace Insert Venting Demystified Gas Wood Burning Inserts Direct Vent

Sawmill Creek Woodworking Community

Fireplace Insert Guide Fireplaces Direct Learning Center

Related Posts