Pellet Stove Fireplace Insert Installation: A Comprehensive Guide

The increasing popularity of pellet stoves as an efficient and environmentally conscious heating solution has led to a surge in pellet stove fireplace insert installations. These inserts offer a practical and aesthetic upgrade to existing masonry fireplaces, transforming them into effective heating appliances. Installing a pellet stove fireplace insert is a complex process that necessitates careful planning, adherence to safety regulations, and a thorough understanding of the installation procedures. This article provides a detailed overview of the key aspects of pellet stove fireplace insert installation.

Understanding Pellet Stove Fireplace Inserts

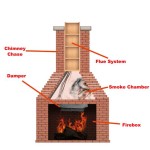

A pellet stove fireplace insert is essentially a self-contained pellet stove designed to fit directly into the existing firebox of a masonry fireplace. Unlike freestanding pellet stoves, inserts utilize the fireplace's existing structure and chimney to function. They burn compressed wood or biomass pellets, providing a consistent and controllable heat output. The benefits of using a pellet stove fireplace insert include increased heating efficiency compared to traditional wood-burning fireplaces, reduced emissions, and a cleaner burning process. They also offer convenient features like automatic ignition, thermostatic control, and programmable timers, allowing for precise temperature regulation and energy conservation.

Selecting the appropriate pellet stove insert is crucial. Factors to consider include the size of the area to be heated, the existing fireplace's dimensions, the home's insulation levels, and the desired heat output (measured in BTU - British Thermal Units). The insert's hopper capacity, which determines how frequently pellets need to be refilled, is another important consideration. It's advisable to consult with a qualified heating professional to determine the optimal insert size and model for specific needs. Choosing an EPA-certified model ensures compliance with environmental regulations and guarantees a cleaner and more efficient burn.

Before commencing any installation work, a thorough inspection of the existing fireplace and chimney is paramount. This involves checking for structural integrity, identifying any cracks or damage, and ensuring that the chimney is clean and free from obstructions. A professional chimney sweep should be hired to perform a comprehensive cleaning and inspection, as creosote buildup can pose a significant fire hazard. Any necessary repairs to the fireplace or chimney should be completed before installing the pellet stove insert.

Preparing the Fireplace for Installation

The preparation phase involves several critical steps to ensure a safe and effective installation. The first step is to measure the firebox dimensions accurately. This includes the width, height, and depth of the firebox, as well as the size of the fireplace opening. These measurements are essential for selecting an insert that will fit properly within the existing fireplace.

Next, the fireplace opening may need to be modified to accommodate the insert's surround panel, which covers the gap between the insert and the fireplace opening. This can involve removing existing trim or masonry to create a flush surface for the surround panel. Care should be taken to avoid damaging the fireplace structure during this process.

The hearth, the non-combustible area in front of the fireplace opening, must also meet specific requirements. Most pellet stove insert manufacturers specify minimum hearth extension dimensions to protect flooring from sparks and embers. If the existing hearth does not meet these requirements, it may need to be extended with non-combustible materials like brick, stone, or concrete. The hearth extension should be installed according to local building codes and the insert manufacturer's instructions.

A crucial aspect of preparing the fireplace is ensuring proper ventilation. Pellet stove inserts require a dedicated chimney liner to vent exhaust gases safely and efficiently. The existing chimney often needs to be relined with a stainless steel liner that is specifically designed for pellet stoves. This liner is typically installed from the top of the chimney down to the insert's flue collar. The liner should be properly insulated to prevent condensation and maintain adequate draft. The size of the liner will depend on the insert's specifications and local building codes.

The Installation Process: Step-by-Step Guide

The installation process typically involves several key steps, each of which must be performed with precision and attention to detail. Safety precautions, including wearing appropriate personal protective equipment (PPE) such as gloves, eye protection, and a dust mask, are essential throughout the installation.

The first step is to connect the pellet stove insert to the chimney liner. This involves attaching the liner to the insert's flue collar using a secure and airtight connection. The connection should be properly sealed to prevent exhaust gases from leaking into the home. High-temperature silicone sealant is often used for this purpose.

Next, the pellet stove insert is carefully slid into the fireplace opening. This process may require some maneuvering to ensure that the insert is properly aligned and seated within the firebox. The insert should be positioned so that the surround panel fits flush against the fireplace opening.

Once the insert is in place, the surround panel is installed to cover the gap between the insert and the fireplace opening. The surround panel is typically attached to the insert using screws or clips. It is important to ensure that the surround panel is securely fastened and that there are no gaps or openings that could allow air to escape.

Electrical connections are a crucial aspect of the installation process. Pellet stove inserts require a dedicated electrical circuit to power the blower fan, auger motor, and control panel. A licensed electrician should be hired to install a properly grounded electrical outlet near the fireplace. The insert should be connected to the electrical outlet according to the manufacturer's instructions. It is essential to ensure that the electrical connections are safe and comply with local electrical codes.

Testing the insert is the final step in the installation process. This involves starting the insert and verifying that all components are functioning correctly. The blower fan should be blowing air, the auger motor should be feeding pellets into the firebox, and the control panel should be displaying the correct temperature settings. The exhaust gases should be venting properly through the chimney liner. Any issues or malfunctions should be addressed before using the insert for heating purposes.

Following the installation, it is important to carefully read and understand the insert's operating manual. The manual provides detailed instructions on how to operate the insert safely and efficiently, as well as how to perform routine maintenance. Regular cleaning of the insert and chimney is essential to ensure optimal performance and prevent fire hazards. A professional chimney sweep should be hired to inspect and clean the chimney at least once a year.

Local building codes and regulations often govern the installation of pellet stove fireplace inserts. It is essential to obtain the necessary permits and inspections before commencing any installation work. Failure to comply with local codes can result in fines or even the removal of the insert. Contacting the local building department is the best way to ensure compliance with all applicable regulations.

Proper maintenance is crucial for the longevity and efficiency of a pellet stove insert. Regular cleaning is paramount to prevent buildup of ash and creosote, which can impair performance and pose a fire risk. The frequency of cleaning depends on usage, but generally, the firebox should be cleaned weekly, and the venting system inspected and cleaned annually by a qualified professional. Promptly addressing any mechanical issues, such as auger malfunctions or blower failures, is also essential. Refer to the manufacturer's manual for specific maintenance recommendations.

Sawmill Creek Woodworking Community

Fireplace Insert Installation Wood Inserts Gas Pellet And Electric

Pellet Fireplace Inserts Lopi Stoves Made In Usa

Pellet Inserts Available For Installation Upgrade Your Fireplace

Wood Stoves Pellet Gas Fireplace Inserts

Pellet Burning Fireplace Inserts Sierra Hearth And Home

Wood Pellet Fireplace Inserts Martin S And Service Butler Pa

Pellet Stove Inserts Atlanta The Fireplace Place

Pellet Fireplace Inserts Insert Installation In Burlington Wi More

Pellet Stove Fireplace Inserts Insert Installation

Related Posts