Understanding and Maintaining Your Old Heatilator Fireplace

Heatilator fireplaces, renowned for their innovative heat-circulating design, were a popular choice for homeowners seeking supplemental heating solutions. These fireplaces, often dating back several decades, offered an alternative to traditional masonry fireplaces, boasting improved efficiency in distributing warmth throughout a living space. Understanding the design, operation, and maintenance requirements of an older Heatilator fireplace is crucial for safety and optimal performance.

This article aims to provide a comprehensive overview of old Heatilator fireplaces, covering their construction, operating principles, common issues, and essential maintenance practices. Recognizing the specific characteristics of these older models can help homeowners troubleshoot problems, ensure safe operation, and potentially extend the lifespan of their Heatilator fireplace.

Key Point 1: Identifying Your Heatilator Fireplace and Its Components

The first step in understanding an old Heatilator fireplace is to identify its specific model, if possible. While many older models lack readily available identifying marks, certain features are characteristic of the Heatilator design. These fireplaces typically feature a metal firebox surrounded by an outer metal shell, creating an air chamber. Cool air is drawn into this chamber from floor level, heated by the firebox, and then circulated back into the room through vents located near the top of the fireplace opening.

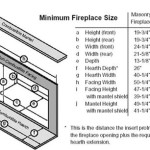

Key components to identify include the firebox itself, typically constructed of heavy-gauge steel or cast iron. The outer shell forms the air chamber and contains vents for air intake and output. Blower fans, if present, are located within the air chamber and are designed to enhance air circulation. Dampers control airflow through the chimney flue and are essential for proper draft and preventing backdrafting. Understanding the location and function of each component is vital for effective inspection and maintenance.

The chimney system is another integral part of the Heatilator fireplace. Older models may utilize masonry chimneys or prefabricated metal chimneys. Regardless of the type, a clean and properly functioning chimney is essential for safe operation. Creosote buildup within the chimney poses a significant fire hazard and must be addressed through regular cleaning and inspection.

Many older Heatilator fireplaces may have optional features such as glass doors, decorative fronts, or thermostat controls for the blower fan. Identifying these features can help determine the specific model and operating characteristics of the fireplace. Documentation, if available, can further assist in understanding the fireplace's original design and intended use.

Key Point 2: Common Problems and Troubleshooting

Older Heatilator fireplaces, like any mechanical system, are prone to certain problems associated with age and wear. Recognizing these common issues is crucial for prompt diagnosis and repair, preventing further damage or safety hazards.

One frequent problem is corrosion within the firebox. Repeated exposure to high temperatures and combustion byproducts can lead to rust and deterioration of the metal. Inspecting the firebox for signs of corrosion, cracks, or warping is essential. Severe corrosion may necessitate firebox repair or replacement.

Another common issue is blower fan malfunction. Over time, the blower motor may wear out, become noisy, or fail to operate altogether. Dust and debris accumulation can also impede fan performance. Cleaning and lubricating the fan motor may restore functionality; however, replacement may be necessary in some cases.

Damper issues are also prevalent in older fireplaces. The damper mechanism may become stuck, rusted, or damaged, preventing proper opening and closing. A malfunctioning damper can lead to drafts, inefficient heating, and even carbon monoxide buildup. Inspecting the damper for damage and ensuring smooth operation is vital. Lubricating the damper mechanism or replacing damaged parts may be necessary.

Creosote buildup in the chimney is a significant safety concern. Incomplete combustion of wood releases volatile compounds that condense in the chimney flue, forming creosote. Regular chimney sweeping performed by a qualified professional is essential to remove creosote and prevent chimney fires. Signs of excessive creosote buildup include thick, tar-like deposits inside the chimney and a persistent smoky odor even when the fireplace is not in use.

Smoke entering the room when the fireplace is in use is another indication of a problem. This can be caused by insufficient draft, a blocked chimney, a closed damper, or negative air pressure within the house. Checking for obstructions in the chimney, ensuring the damper is fully open, and addressing air pressure imbalances can help resolve this issue.

Key Point 3: Essential Maintenance Practices for Longevity and Safety

Regular maintenance is crucial for ensuring the safe and efficient operation of an old Heatilator fireplace. Properly maintained, these fireplaces can provide supplemental heat for many years. Neglecting maintenance, however, can lead to safety hazards and costly repairs.

The most important maintenance practice is annual chimney sweeping and inspection. A qualified chimney sweep can remove creosote buildup, inspect the chimney for damage, and identify any potential problems. This service should be performed at least once a year, or more frequently if the fireplace is used heavily.

Regular inspection of the firebox and other components is also essential. Look for signs of corrosion, cracks, or warping. Clean the firebox regularly to remove ash and debris. Inspect the blower fan for proper operation and clean or lubricate it as needed. Inspect and maintain the damper mechanism to ensure smooth operation.

When burning wood, it is crucial to use seasoned hardwood. Green or wet wood produces more smoke and creosote, increasing the risk of chimney fires. Store wood properly to keep it dry and prevent insect infestations. Avoid burning treated wood, painted wood, or artificial logs, as these can release harmful chemicals into the air.

Ensure proper ventilation within the room when the fireplace is in use. Opening a window slightly can help prevent negative air pressure and ensure adequate draft. Consider installing a carbon monoxide detector near the fireplace to provide an early warning of potential carbon monoxide buildup.

If repairs are needed, it is important to use qualified technicians familiar with old Heatilator fireplaces. Some parts may be difficult to find, requiring fabrication or sourcing from specialty suppliers. Attempting repairs without proper knowledge and experience can be dangerous and may void warranties. The services of a professional chimney sweep and qualified technician can help ensure safe and efficient operation of your old Heatilator fireplace, contributing to years of enjoyment and supplemental heat.

Update Your Heatilator Mark 123 Fireplace In No Time

Heatilator

Update Your Heatilator Mark 123 Fireplace In No Time

Any Reason To Rip Out Old Heatilator Hearth Com Forums Home

Heatilator

Remove Or Cover Up Old Heatilator Vents Hearth Com Forums Home Fireplace Brick Makeover

Heatilator Fireplaces Canadian Home Inspection Services

Heatilator Fireplace Brochure Manuals Guides Parts Fans

Fireplace Heatilator Question Lumberjocks Woodworking Forum

Heatilator Inc 1954 Fireplace Unit Residential Heating Vintage Catalog On Ebid United States 172555845