Masonry Fireplace Construction Details

Masonry fireplaces, characterized by their robust construction and enduring appeal, offer a captivating focal point in residential interiors. Their construction demands meticulous planning, adherence to building codes, and skillful execution of various stages. This detailed examination explores the foundational elements, structural components, and essential construction details involved in crafting a safe and effective masonry fireplace.

The construction of a masonry fireplace starts with a solid foundation, typically a reinforced concrete slab or footing below the frost line. This foundation distributes the significant weight of the fireplace and chimney to the underlying soil, preventing settling and potential structural damage. The dimensions of the foundation are determined by the size and design of the fireplace, taking into account factors such as the firebox size, chimney height, and overall weight distribution.

Accurate layout and precise measurements are critical from the outset. This ensures that the fireplace is properly aligned with the room's design and meets required clearances from combustible materials. Building permits are usually required before construction commences, and these permits typically require detailed drawings outlining the construction specifications, materials used, and adherence to relevant building codes and safety regulations.

Firebox Construction

The firebox is the heart of the fireplace, where combustion occurs. It is constructed using fire-resistant materials like firebrick laid in a high-temperature refractory mortar. Firebrick can withstand the intense heat generated during burning and prevent the heat from transferring to surrounding combustible building materials. The dimensions of the firebox are carefully calculated to ensure efficient combustion and adequate draft.

The back and side walls of the firebox are typically sloped inward and upward to reflect heat into the room and improve combustion efficiency. The angle, often around 45 degrees, helps to direct radiant heat outwards and helps to create a smooth airflow. The firebox design also includes a hearth, which extends outwards into the room and serves as a protective barrier and a place to rest burning logs. The hearth must meet specific requirements for size and non-combustibility to prevent sparks or embers from igniting nearby flooring or furniture.

A lintel, typically made of steel or reinforced concrete, spans the top of the firebox opening. Its function is to support the weight of the masonry above the opening and prevent it from collapsing into the firebox. The size and strength of the lintel are determined by the width of the firebox opening and the weight of the overlying masonry. The lintel must be properly installed and anchored to ensure its structural integrity.

Smoke Chamber and Smoke Shelf

Above the firebox lies the smoke chamber, a tapered section that narrows from the firebox to the chimney flue. Its primary function is to collect smoke and hot gases from the firebox and direct them into the chimney. The smoke chamber walls are typically smooth and angled to facilitate the efficient flow of smoke and to prevent the formation of eddies that could impede the draft.

At the base of the smoke chamber is the smoke shelf, a horizontal projection that extends back from the firebox opening. The smoke shelf serves to deflect downdrafts, which are caused by wind blowing down the chimney. By deflecting downdrafts, the smoke shelf helps to prevent smoke from being forced back into the room. It also provides a collection point for debris that may fall down the chimney, preventing it from obstructing the firebox.

The interior surfaces of the smoke chamber are ideally parged with refractory mortar to smooth them and seal any cracks or crevices. This helps to improve the flow of smoke and to prevent the buildup of creosote, a highly flammable substance that can accumulate in chimneys.

Chimney Construction

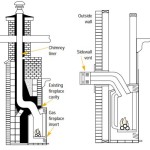

The chimney is a vertical structure that extends from the smoke chamber to above the roofline. Its primary function is to provide a draft that draws smoke and hot gases away from the firebox and exhausts them into the atmosphere. The height of the chimney is a crucial factor in determining the strength of the draft, and it must meet specific requirements based on the roof pitch and surrounding structures.

The chimney is constructed of masonry materials such as brick, stone, or concrete block. It is lined with a flue liner, which can be made of clay, ceramic, or metal. The flue liner provides a smooth, heat-resistant surface that protects the chimney masonry from the corrosive effects of combustion gases and helps to improve the draft. The flue liner must be properly sized to match the firebox opening and to ensure efficient smoke removal.

The chimney is typically capped with a chimney cap, which prevents rain, snow, and debris from entering the chimney. The chimney cap also helps to prevent animals from nesting in the chimney and can improve the draft by directing wind away from the flue opening. A spark arrestor is often incorporated into the chimney cap to prevent sparks from escaping and potentially igniting nearby vegetation or structures.

Proper clearance from combustible materials is essential throughout the chimney's construction. Building codes specify minimum clearances that must be maintained between the chimney and wooden framing, roofing materials, and other combustible elements. These clearances are designed to prevent fires caused by heat transfer from the chimney.

Draft Considerations and Damper Installation

An efficient draft is crucial for the proper functioning of a masonry fireplace. The draft is created by the difference in pressure between the hot gases in the chimney and the cooler air outside. Several factors influence the draft, including the chimney height, flue size, firebox dimensions, outdoor temperature, and wind conditions. Insufficient draft can lead to smoke spillage into the room, while excessive draft can result in rapid fuel consumption.

A damper is installed in the chimney, typically above the smoke chamber or at the top of the chimney, to regulate the draft. The damper can be opened to allow smoke and gases to escape when the fireplace is in use and closed to prevent heat loss when the fireplace is not being used. Dampers are available in various designs, including throat dampers, top-sealing dampers, and cast-iron dampers. The choice of damper depends on the specific fireplace design and the desired level of energy efficiency.

The installation of the damper requires careful attention to ensure proper sealing and operation. The damper must fit snugly within the chimney and should be easy to open and close. A properly functioning damper can significantly improve the energy efficiency of the fireplace and prevent unwanted drafts from entering the room.

01 Fireplace Detail Masonry Brick

Concrete Masonry Fireplaces Entire Tek

Fireplaces A Construction Primer Masonry Fireplace Chimney Design Dimensions

Chapter 10 Chimneys And Fireplaces San Antonio Residential Code 2024 Upcodes

Result For Fireplace Details Masonry Chimney Design Brick And Stone

Building A Fireplace Fine Homebuilding

Chapter 10 Chimneys And Fireplaces New York State Residential Code 2024 Upcodes

Masonry Chimney Construction Guidelines

Camp Stoves And Fireplaces

Residential Fireplaces Details And Construction

Related Posts