Martin Fireplace Insert Parts: A Comprehensive Guide

Martin Fireplace Inserts are renowned for their efficiency and ability to transform existing fireplaces into effective heating sources. These inserts, however, are complex systems comprised of numerous components, each crucial to its overall functionality. Understanding the various Martin Fireplace Insert parts is essential for proper maintenance, troubleshooting, and eventual repair. This article provides a detailed overview of the key components, their functions, and the importance of using genuine Martin replacement parts when necessary.

The longevity and performance of a Martin Fireplace Insert hinge on the quality of its components. Like any mechanical appliance, these inserts are subject to wear and tear. Recognizing the individual parts, their purpose, and the symptoms of potential failure allows homeowners to proactively address issues before they escalate into more significant problems. This proactive approach can save on costly repairs, extend the lifespan of the insert, and ensure optimal heating efficiency.

Key Components of a Martin Fireplace Insert

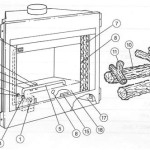

A Martin Fireplace Insert can be broken down into several essential categories based on function. These categories include combustion, venting, control, and aesthetics. Within each category are individual parts that contribute to the overall operation of the unit. Identifying these parts is the first step in understanding how the insert functions and how to maintain it properly.

The combustion chamber is the heart of the insert where the fuel, typically wood or gas, is burned to generate heat. This chamber is constructed from durable materials such as cast iron or steel to withstand high temperatures. Key parts within the combustion chamber include the firebox lining, air tubes, baffle, and grate (for wood-burning models). The venting system is responsible for safely expelling combustion byproducts, like smoke and gases, from the fireplace insert. The venting system consists of pipes, connectors, and potentially a chimney liner. The control system regulates the airflow, fuel supply, and overall operation of the insert. The control system includes components like the air control damper, gas valve (for gas models), and potentially an electronic control board. The aesthetic components, while not directly related to the function of the insert, contribute to its appearance. These parts include the door, faceplate, and decorative trim.

Proper maintenance and knowledge of these core components are necessary to ensure optimal performance and a prolonged lifespan for the fireplace insert.

Combustion Chamber Parts: Functionality and Maintenance

The combustion chamber is the most critical area of a Martin Fireplace Insert. It's where the combustion process transforms fuel into heat. The parts within this chamber are subjected to extreme temperatures and corrosive byproducts, making them prone to wear and requiring regular inspection and maintenance.

The firebox lining, often made of firebrick or ceramic fiberboard, protects the outer shell of the insert from the intense heat of the fire. These linings are designed to insulate the firebox and reflect heat back into the combustion chamber, improving efficiency. Over time, firebrick can crack and crumble, while ceramic fiberboard can become brittle and degrade. Signs of wear on the firebox lining, like cracks or missing pieces, indicate the need for replacement to maintain optimal insulation and prevent damage to the insert's structure.

Air tubes are strategically placed within the firebox to introduce preheated air into the combustion zone. This secondary air injection promotes more complete combustion of the fuel, reducing emissions and increasing heat output. Blocked or damaged air tubes can negatively affect the insert's efficiency and lead to increased smoke production. Routine cleaning to remove creosote and ash buildup is essential for maintaining proper airflow through these tubes.

The baffle, located at the top of the firebox, is designed to slow down the flow of hot gases, allowing for more complete combustion and heat transfer. The baffle also helps to prevent smoke from escaping into the room when the door is opened. A damaged or missing baffle will drastically reduce efficiency and increase emissions. Regular inspection for warping, cracking, or deterioration is crucial. Replacement is necessary if any damage is detected.

For wood-burning models, the grate supports the wood within the firebox, allowing air to circulate underneath and promote combustion. Grates are subject to high temperatures and can warp, crack, or break over time. A damaged grate should be replaced to ensure proper airflow and efficient burning.

Understanding the function and maintenance requirements of each combustion chamber component is paramount for safe and efficient operation.

Venting System Components: Safety and Efficiency

The venting system of a Martin Fireplace Insert is vital for safely removing combustion byproducts from your home. A properly functioning venting system ensures that harmful gases like carbon monoxide are safely expelled, preventing health hazards and maintaining indoor air quality. Regular inspection and maintenance are essential for the safety and efficiency of this system.

The vent pipes, typically constructed of stainless steel or other approved materials, connect the fireplace insert to the chimney. These pipes must be properly sized and installed to ensure adequate draft and prevent backdrafting. Inspecting these pipes for corrosion, leaks, or damage is crucial. Any signs of deterioration warrant immediate replacement.

Connectors are used to join sections of vent pipe and to connect the vent pipe to the fireplace insert and the chimney. These connectors must be properly sealed to prevent leaks. Inspecting these connections for tightness and proper sealing is essential. Damaged or loose connectors should be replaced immediately.

A chimney liner is often required when installing a fireplace insert into an existing masonry chimney. The liner provides a smooth, continuous flue that is properly sized for the insert. This helps to improve draft and prevents condensation from damaging the chimney structure. Inspecting the chimney liner for cracks, gaps, or deterioration is essential. A damaged chimney liner should be repaired or replaced to ensure safe and efficient venting.

The chimney cap prevents rain, snow, and debris from entering the venting system. It also helps to prevent downdrafts and improve draft. Inspecting the chimney cap for damage or blockage is important. A damaged or blocked chimney cap should be repaired or replaced.

Creosote buildup within the venting system can create a fire hazard. Regular chimney sweeping is essential to remove creosote deposits and maintain proper airflow. A professional chimney sweep should be hired to inspect and clean the venting system annually.

The integrity of the venting system directly impacts the safety and efficiency of the fireplace insert. Regular maintenance, including inspections, cleaning, and timely replacements, is crucial for preventing hazards and ensuring optimal performance.

Control System Components: Regulation and Operation

The control system of a Martin Fireplace Insert regulates its operation, ensuring proper airflow, fuel supply (for gas models), and overall performance. The specific components within the control system vary depending on the type of insert (wood-burning or gas), but understanding their function is essential for troubleshooting and maintaining optimal performance.

The air control damper regulates the amount of air entering the firebox in wood-burning models. This control allows the user to adjust the burn rate and heat output. Inspecting the damper for smooth operation and proper sealing is critical. A stuck or damaged damper can significantly impact the insert's efficiency and potentially lead to unsafe operating conditions.

For gas models, the gas valve controls the flow of gas to the burner. The gas valve is typically controlled by a thermostat or a manual control knob. It is a critical safety component. Any suspected malfunction of the gas valve should be addressed immediately by a qualified technician.

Some Martin Fireplace Inserts are equipped with electronic control boards that regulate various functions, such as ignition, fan speed, and temperature control. These boards are susceptible to damage from power surges or extreme temperatures. Any issues with these control boards should be addressed by a qualified technician who can diagnose and replace the component if necessary.

The thermostat (for gas models) senses the room temperature and adjusts the gas flow to maintain the desired temperature. A malfunctioning thermostat can lead to inconsistent heating or a complete failure of the insert to operate. Testing and replacing the thermostat may be necessary.

The blower fan circulates heated air from the insert into the room, improving heating efficiency and distribution. The fan can become noisy or stop working over time. Cleaning the fan blades and lubricating the motor may resolve the issue. If the fan is damaged or worn out, it should be replaced.

The probe or sensor monitors the temperature of the insert's firebox or flue. This information is used to regulate the operation of the insert and ensure safe operating conditions. A malfunctioning probe or sensor can lead to inaccurate temperature readings and potentially unsafe operation. Replacing the probe or sensor may be necessary.

The control system is often the most complex part of a modern Martin Fireplace Insert. Regular inspection and prompt attention to any malfunctions are key to ensuring safe, efficient, and reliable operation. Due to the complexity and potential safety hazards associated with gas and electrical components, it is recommended that qualified technicians handle repairs and replacements within the control system.

Nestor Martin Fb50 Insert Multifuel Stove Spare Parts Diagrams Page 1 Firebox Stoves

Md42i Martin Wood Burning Fireplace Parts At Fireplaceparts Com

Nestor Martin Fb80 Insert Multifuel Stove Spare Parts Diagrams Page 3 Firebox Stoves

Matte Black Martin Fireplace Door For Sc36 Sc36mb Scf36 Scf36i

Nestor Martin It13 Insert Wood Multifuel Stove Parts Diagrams Page 2 Firebox Stoves

Nestor Martin Fb100 Insert Multifuel Stove Spare Parts Diagrams Page 4 Firebox Stoves

Vf3d Martin Gas Vent Free Firebox Parts At Fireplaceparts Com

Matte Black Martin Sa39 Fireplace Door

Nestor Martin It33 Insert Wood Multifuel Stove Parts Diagrams Page 1 Firebox Stoves

Martin Fireplace Doors Brick Anew Free

Related Posts