Make Your Own Fireplace Insert: A Comprehensive Guide

Fireplace inserts offer an efficient and aesthetically pleasing way to heat a home. They function by converting an existing open fireplace into a sealed combustion system, significantly increasing heating efficiency and reducing emissions. While commercially available inserts provide convenience, crafting a custom insert can offer cost savings and allow for tailoring the design to specific needs and preferences. This article provides a detailed overview of the process, considerations, and potential challenges involved in constructing a do-it-yourself fireplace insert.

The primary advantage of building a fireplace insert is the potential for substantial cost reduction. Purchasing a professionally manufactured insert can be a significant investment, encompassing the cost of the unit itself, delivery, and professional installation. Constructing a unit independently bypasses these expenses, allowing resources to be focused solely on materials and specialized tools. However, it is crucial to understand that DIY projects also entail inherent risks and require a thorough understanding of combustion principles, safety regulations, and fabrication techniques.

Building a fireplace insert is a complex undertaking best suited for individuals with experience in metalworking, welding, and basic HVAC systems. It involves a considerable amount of planning, precise measurements, and meticulous execution. Improperly designed or constructed inserts can present serious safety hazards, including carbon monoxide poisoning, chimney fires, and structural damage to the home. Prior to commencing any work, a thorough assessment of the existing fireplace and chimney is necessary, along with a comprehensive understanding of local building codes and regulations regarding fireplace inserts and wood-burning appliances.

Planning and Design Considerations

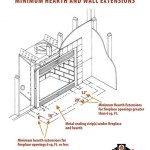

The initial stage of constructing a fireplace insert involves meticulous planning and design. The dimensions of the existing fireplace opening are critical and must be measured precisely. These measurements will dictate the overall size and shape of the insert. A detailed sketch or CAD drawing is highly recommended, outlining all components, including the firebox, heat exchanger, blower assembly, and flue connection.

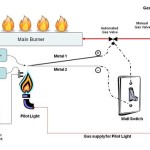

The firebox is the core of the insert, responsible for containing the fire and transferring heat. The material selection for the firebox is crucial. Typically, heavy-gauge steel is used due to its high heat resistance and durability. The thickness of the steel will influence the insert's ability to withstand high temperatures and potential warping over time. Considerations for proper airflow and combustion are paramount. Primary air inlets must be strategically positioned to provide sufficient oxygen for efficient burning, while secondary air inlets can enhance combustion and reduce smoke production. The firebox design should also incorporate a baffle system to maximize heat retention and direct exhaust gases towards the flue.

The heat exchanger is responsible for extracting heat from the firebox and transferring it to the surrounding air. Various designs can be employed, including a series of steel tubes or a wraparound air jacket. The design should maximize surface area to facilitate efficient heat transfer. The placement and configuration of the heat exchanger will significantly impact the insert's overall heating efficiency. A blower assembly is typically incorporated to circulate heated air into the room. The selection of a suitable blower fan depends on the desired airflow rate and noise level. The fan should be positioned to draw air across the heat exchanger and discharge it through vents on the front of the insert.

The flue connection is the point where the insert connects to the existing chimney. It is essential to ensure a proper seal and adequate draft to prevent smoke and carbon monoxide from entering the home. The flue connection should be sized appropriately to accommodate the exhaust gases produced by the fire. A stainless steel chimney liner is often recommended to improve draft and prevent corrosion of the existing chimney.

Material Selection and Fabrication Techniques

Choosing the correct materials and employing appropriate fabrication techniques are essential to ensure the insert's safety, durability, and efficiency. As previously mentioned, heavy-gauge steel is the preferred material for the firebox due to its high heat resistance. Different grades of steel are available, each with varying properties. Selecting a grade suitable for high-temperature applications is crucial.

Welding is a critical aspect of fabricating a fireplace insert. Competent welding skills are necessary to create strong and airtight seams. Different welding processes, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas), can be employed. The choice of welding process depends on the type of steel being used and the desired weld quality. Proper safety precautions, including wearing appropriate protective gear, are crucial during welding operations.

Cutting and shaping the steel components require specialized tools, such as a plasma cutter or angle grinder. These tools allow for precise cuts and shaping of the steel to match the design specifications. Accurate measurements and careful cutting are essential to ensure proper fit and alignment of the components during assembly. Bending and forming the steel may also be necessary to create the desired shapes. This can be accomplished using a metal brake or other specialized forming tools.

The blower assembly typically consists of a centrifugal fan, motor, and housing. The selection of a suitable fan depends on the desired airflow rate and noise level. The fan should be rated for continuous operation and designed to withstand the temperatures encountered within the insert. The housing should be constructed of durable materials, such as steel or aluminum, and designed to protect the fan from debris and damage.

Installation and Safety Considerations

Proper installation is crucial to ensure the safe and efficient operation of the fireplace insert. Before installing the insert, the existing fireplace and chimney should be thoroughly inspected for any signs of damage or deterioration. Any necessary repairs should be completed before proceeding with the installation. The chimney should be cleaned and inspected by a qualified chimney sweep to ensure it is free of obstructions and creosote buildup. A stainless steel chimney liner is often recommended to improve draft and prevent corrosion of the existing chimney.

The insert should be carefully positioned within the fireplace opening, ensuring adequate clearance from combustible materials. The manufacturer's instructions should be consulted for specific clearance requirements. The flue connection should be securely attached to the chimney, ensuring a tight seal. A high-temperature sealant should be used to prevent leaks. The blower assembly should be properly wired to a dedicated electrical circuit, following all applicable electrical codes. A ground fault circuit interrupter (GFCI) outlet is recommended for added safety.

Carbon monoxide (CO) detectors are essential safety devices that should be installed in the home, especially near sleeping areas. Carbon monoxide is a colorless and odorless gas that can be produced by incomplete combustion. CO detectors provide an early warning of the presence of carbon monoxide, allowing occupants to evacuate the premises and seek medical attention. Regular maintenance of the fireplace insert and chimney is crucial to prevent malfunctions and ensure safe operation. The chimney should be inspected and cleaned annually by a qualified chimney sweep. The insert should be regularly inspected for any signs of damage or deterioration. Any necessary repairs should be completed promptly.

It is also important to operate the fireplace insert according to the manufacturer's instructions. Only approved fuels should be burned. Overloading the firebox can lead to overheating and potential damage. The air controls should be adjusted to optimize combustion and minimize smoke production. The ash should be removed regularly to prevent buildup and maintain proper airflow. The area around the fireplace insert should be kept clear of combustible materials, such as curtains, furniture, and paper.

Constructing a fireplace insert involves inherent risks and requires a thorough understanding of combustion principles, safety regulations, and fabrication techniques. Consulting with experienced professionals, such as HVAC technicians, welders, and chimney sweeps, is highly recommended. Furthermore, obtaining the necessary permits and inspections from local building authorities is crucial to ensure compliance with safety regulations and building codes. This helps protect the homeowner and ensures the insert is installed and operated safely. It is important to understand that safety should always be the top priority when undertaking such a project.

How To Build A Diy Built In Fireplace With An Electric Insert The Creative Mom

Diy Fireplace With Electric Insert Angela Marie Made

How To Diy An Amazing Electric Fireplace Surround And Mantle Drawer

How To Build A Fireplace Red Cottage Chronicles

How To Build A Diy Fireplace With Electric Insert H2obungalow

How To Build A Diy Fireplace Surround For Your Electric Insert Hand Treated Home

How To Build A Diy Fireplace With Electric Insert Mantle Faux

Diy How To Build A Fireplace In One Weekend Whitney Hansen Money Coaching

Diy Fireplace With Electric Insert Angela Marie Made

25 Diy Faux Fireplace Ideas Build Your Own Fake Suite 101