Large Wood Burning Fireplace Inserts: Efficiency, Ambiance, and Installation

Large wood-burning fireplace inserts provide a solution for homeowners seeking to enhance the heating efficiency and aesthetic appeal of existing masonry fireplaces. These inserts, designed to fit directly into the firebox of a traditional fireplace, offer a controlled and efficient means of burning wood for supplemental heat, while also contributing to the ambiance of a living space. The size of the insert is a critical factor in determining its heating capacity and compatibility with the existing fireplace.

This article examines the key considerations surrounding large wood-burning fireplace inserts, including their benefits, selection criteria, installation processes, and safety precautions. Understanding these aspects is crucial for homeowners considering this heating alternative, ensuring a safe, efficient, and aesthetically pleasing integration into their homes.

Enhanced Heating Efficiency

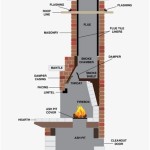

Traditional open-hearth fireplaces are notoriously inefficient heaters. A significant portion of the heat generated escapes up the chimney, resulting in minimal warmth being transferred to the room. Large wood-burning fireplace inserts are designed to address this inefficiency. They employ a closed combustion system, which significantly reduces heat loss up the chimney. This closed system allows for a more complete combustion of the wood, extracting more heat from the fuel and minimizing creosote buildup.

The firebox of an insert is typically constructed from cast iron or steel, materials known for their excellent heat retention and radiant heat transfer properties. The body of the insert radiates heat into the room, while internal blowers circulate warm air, further enhancing heat distribution. This combination of radiant and convection heating makes inserts significantly more effective at warming a space compared to traditional fireplaces. Many modern inserts also incorporate features such as catalytic combustors or secondary air injection systems to further improve combustion efficiency and reduce emissions.

The efficiency of a wood-burning fireplace insert is often measured by its heating capacity, typically expressed in BTUs (British Thermal Units). Large inserts are capable of generating substantial heat, sufficient to warm larger rooms or even entire homes in some cases. The exact heating capacity will vary depending on the insert's size, design, and the quality of the wood being burned. Homeowners should carefully consider their heating needs and the size of their living space when selecting an insert to ensure adequate heating performance.

Beyond heat output, efficiency also translates to fuel savings. Because inserts burn wood more completely, they require less wood to generate the same amount of heat compared to an open fireplace. This can result in significant cost savings over the long term, particularly in areas where firewood is readily available and affordable.

Selecting the Right Size and Features

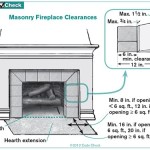

Choosing the appropriate size of a wood-burning fireplace insert is paramount to both its functionality and safety. The insert must be compatible with the firebox dimensions of the existing fireplace. Measuring the height, width, and depth of the firebox is essential before beginning the selection process. Manufacturers typically provide detailed specifications outlining the minimum and maximum firebox dimensions suitable for their inserts.

Oversizing an insert can lead to overheating and potential damage to the fireplace structure, while undersizing can result in insufficient heating. It’s critical to select an insert that fits snugly within the firebox, allowing for proper airflow and heat circulation. Professional installers can provide valuable assistance in determining the ideal size based on the specific dimensions of the fireplace and the heating requirements of the space.

In addition to size, homeowners should consider the features and technologies offered by different models. Catalytic combustors, mentioned previously, are devices that burn off smoke and gases produced during combustion, further reducing emissions and increasing efficiency. Non-catalytic inserts utilize secondary air injection to achieve similar results, burning off unburned gases without the need for a catalytic device. Both technologies contribute to cleaner burning and improved heating performance.

Other features to consider include blower systems, which enhance heat circulation, and adjustable air controls, which allow users to fine-tune the burn rate and heat output. Some inserts also offer aesthetic options, such as different door styles, trim finishes, and log sets, allowing homeowners to customize the insert to match their décor. EPA certification is also an important factor, confirming that the insert meets stringent emission standards.

The material composition of the insert is another consideration. Cast iron inserts are known for their excellent heat retention and durability, while steel inserts tend to heat up more quickly. Both materials are suitable for fireplace inserts, and the choice often comes down to personal preference and budget.

Installation and Safety Considerations

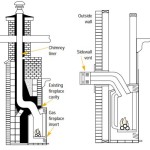

Proper installation is paramount for the safe and efficient operation of a wood-burning fireplace insert. Installation typically involves several steps, including preparing the fireplace, installing a chimney liner, connecting the insert to the liner, and sealing the insert within the firebox. Due to the complexities and potential hazards involved, it is strongly recommended that installation be performed by a qualified professional.

A crucial component of the installation process is the installation of a chimney liner. A chimney liner is a metal pipe that runs the entire length of the chimney, providing a direct and sealed pathway for the exhaust gases to escape. The liner prevents combustion gases from leaking into the home and also protects the chimney structure from the corrosive effects of creosote. It is essential to choose a liner that is specifically designed for use with wood-burning appliances and that meets local building codes.

Once the liner is installed, the insert is carefully positioned within the firebox and connected to the liner. The space between the insert and the firebox is typically sealed with a non-combustible material to prevent air leaks and ensure proper draft. The electrical connections for the blower system, if present, are also made at this time.

Following installation, it is essential to adhere to safety precautions to prevent fires and carbon monoxide poisoning. A carbon monoxide detector should be installed in the home, preferably near sleeping areas. The insert should be inspected and cleaned regularly to remove creosote buildup, which can pose a fire hazard. It is also crucial to burn only seasoned firewood, as green or damp wood produces more smoke and creosote.

Proper maintenance of the chimney and insert is essential for long-term safety and performance. Regular chimney sweeps can remove creosote buildup and identify any potential problems with the chimney structure. The insert itself should be inspected for signs of damage or wear, and any necessary repairs should be performed promptly. Following these safety precautions will help ensure that the wood-burning fireplace insert provides years of safe and efficient heating.

Furthermore, local building codes and regulations must be consulted prior to installation. Permits may be required, and inspections may be necessary to ensure compliance with safety standards. Ignoring these regulations can result in fines and potential safety hazards.

The choice of firewood also plays a significant role in the safety and efficiency of the insert. Hardwoods like oak, maple, and ash burn longer and produce more heat than softwoods like pine. Seasoning wood for at least six months to a year reduces its moisture content, resulting in cleaner burning and less creosote buildup. Storing firewood properly, away from the house and off the ground, helps prevent mold and rot.

Finally, users should be aware of the signs of carbon monoxide poisoning, which can include headache, dizziness, nausea, and fatigue. If any of these symptoms are present, occupants should immediately evacuate the premises and seek medical attention. A working carbon monoxide detector is a vital safety device for any home with a wood-burning appliance.

Large Flush Wood Rectangular Nexgen Fyre Made In America Fireplace Xtrordinair

Ventis Hei240 Wood Fireplace Insert Mace Energy Supply

Wood Inserts Fireplace And Stove The Hearth Doctor Inc

Fpx Large Flush Wood Hybrid Fyre Insert Fireplace Gallery Of Western Michigan

Large Flush Wood Nexgen Fyre Arch Steel Fireplace Inserts Made In Usa Lopi Stoves

Fireplace X Large Flush Wood Nexgen Fyre Insert Olde Towne Chimney

Why A Wood Burning Fireplace Insert Bethesda Md Service

Wood Inserts Fireplace And Stove The Hearth Doctor Inc

Wood Inserts Fireplace Xtrordinair Made In America

Hi500 Hybrid Catalytic Cast Iron Wood Burning Insert By Regency