Installing Gas Logs in a Prefab Fireplace: A Comprehensive Guide

Converting a wood-burning prefabricated (prefab) fireplace to gas logs can enhance convenience and aesthetics, providing the ambiance of a fire without the labor-intensive aspects of wood. However, this conversion requires careful planning and adherence to safety guidelines. This article outlines the necessary steps for installing gas logs in a prefab fireplace, ensuring a safe and efficient installation process.

It is essential to differentiate between a prefab fireplace and a traditional masonry fireplace. A prefab fireplace is a self-contained unit designed for ease of installation and often includes its own venting system. Masonry fireplaces, on the other hand, are constructed on-site from brick or stone. Installing gas logs in a prefab fireplace requires careful consideration of the manufacturer's specifications and limitations, as incorrect installation can compromise the unit's safety and void its warranty.

Prior to commencing any installation work, a thorough inspection of the fireplace and its venting system is necessary. The chimney should be inspected for blockages or damage, and any necessary repairs should be completed before installing the gas logs. Furthermore, it is crucial to verify that the fireplace is approved for use with gas logs. The fireplace's data plate, typically located inside the firebox or on the outside of the unit, will provide this information. If the fireplace is not approved for gas logs, installation should not proceed.

Key Point 1: Selecting the Correct Gas Log Set

The selection of an appropriate gas log set is paramount for both safety and performance. Several factors influence this decision, including the size of the fireplace firebox, the type of gas (natural gas or propane), and the desired heat output. The gas log set must be appropriately sized for the firebox; an oversized set can lead to incomplete combustion and carbon monoxide production, while an undersized set may not provide sufficient heat or visual appeal.

The gas log set must also be compatible with the type of gas available. Natural gas log sets operate at a lower pressure than propane log sets, and interchanging them can create a dangerous situation. Furthermore, the gas log set's BTU (British Thermal Unit) rating should align with the fireplace's capacity. Exceeding the fireplace's maximum BTU rating can overheat the unit and potentially damage the firebox or venting system.

Gas log sets are generally categorized as vented or vent-free. Vented gas logs are designed to be used with the fireplace damper open, allowing the products of combustion to vent through the chimney. Vent-free gas logs, on the other hand, are designed to burn more efficiently and release minimal emissions, allowing them to be used with the damper closed. While vent-free gas logs offer greater energy efficiency, they are subject to stricter regulations and may not be approved for use in all jurisdictions. It is imperative to consult local building codes and regulations before installing vent-free gas logs.

Key Point 2: Proper Gas Line Installation

Connecting the gas supply to the fireplace is a critical step that requires expertise and attention to detail. It is strongly recommended that a qualified gas technician or plumber perform this task to ensure compliance with all applicable codes and regulations. Improper gas line installation can lead to gas leaks, explosions, and carbon monoxide poisoning.

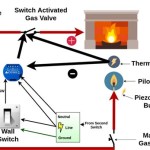

The gas supply line must be of adequate size to provide sufficient gas flow to the log set. Typically, a ½-inch or ¾-inch black iron pipe is used for gas supply lines. The pipe should be properly threaded and sealed with gas-rated pipe sealant to prevent leaks. A shut-off valve should be installed upstream of the gas log set's control valve to allow for easy shut-off in case of emergency or maintenance.

A sediment trap, also known as a drip leg, should be installed in the gas line to capture any debris or moisture that may be present in the gas supply. This prevents these contaminants from entering the gas log set and potentially damaging its components. The sediment trap should be installed vertically, with a capped end pointing downwards, allowing for easy drainage when necessary.

After connecting the gas line, it is essential to perform a leak test using a soapy water solution. Apply the solution to all gas line connections and observe for any bubbles, which indicate a leak. If a leak is detected, immediately shut off the gas supply and tighten the connection or replace the fitting as needed. Repeat the leak test until all connections are leak-free.

Key Point 3: Installing the Gas Logs and Performing Operational Checks

Once the gas line is properly installed and tested, the gas logs can be positioned within the firebox. The manufacturer's instructions should be carefully followed to ensure correct placement. Proper log placement is crucial for optimal flame appearance, heat distribution, and safety. Incorrectly positioned logs can obstruct the burner ports, leading to incomplete combustion and carbon monoxide production.

The burner assembly should be securely mounted within the firebox and connected to the gas supply line. Ensure that all connections are tight and leak-free. The pilot light should be lit according to the manufacturer's instructions, and the main burner should be tested to verify proper ignition and flame pattern. Adjust the flame height and air shutter as needed to achieve a clean, blue flame with minimal yellow tipping.

After the initial installation and testing, it is imperative to conduct a carbon monoxide test to ensure that the gas log set is burning safely. A carbon monoxide detector should be placed near the fireplace and monitored while the gas logs are operating. If carbon monoxide levels exceed acceptable limits, immediately shut off the gas supply and consult a qualified technician to diagnose and resolve the issue.

Finally, review the manufacturer's user manual for specific instructions regarding operation, maintenance, and safety precautions. Regular maintenance, such as cleaning the burner ports and inspecting the gas line connections, is essential for ensuring the long-term safe and efficient operation of the gas log set.

Following these guidelines meticulously will assist in a safe and effective gas log installation within a pre-fabricated fireplace enclosure.

Convert A Wood Fireplace To Gas Full Service Chimney

Fireplace Installation Full Service Chimney Serving Kansas City Area

Prefab Chimneys Fireplaces F A Q Tullahoma Tn 1 Chimney

Efficient Prefab Gas Fireplaces Fireplace Showroom In Tilton Nh

Vent Free Unvented Gas Logs Greenville Sc Blue Sky Chimney

New Prefab Fireplace Install Manufactured Wood Gas

Time To Replace Wood Burning Prefab Fireplace Greenville Sc Blue Sky

All About Prefabricated Fireplaces Chimney Savers

Colorado Springs Co Prefabricated Gas Fireplace Fireplaces Install

New Wood Burning Prefab Fireplaces Complete Fireplace Installs

Related Posts