How to Use a Fireplace Insert Wood Burning System

A fireplace insert is a closed combustion system designed to be installed within an existing masonry fireplace. Unlike open fireplaces, which are notoriously inefficient at heating a home, a wood-burning fireplace insert significantly increases heating efficiency by controlling airflow and directing heat into the room. These inserts are essentially wood stoves engineered to fit snugly inside a fireplace opening, offering a more controllable and effective way to burn wood for heat. Understanding the proper operation of a wood-burning fireplace insert is crucial for maximizing its heating potential, ensuring safety, and prolonging the life of the unit.

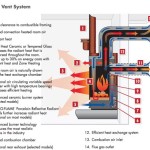

Before even considering lighting a fire, proper installation is paramount. A certified professional should handle the installation process, ensuring the insert is correctly sized for the fireplace and that the chimney is appropriately lined. The chimney liner is a critical component, designed to vent exhaust gases safely and efficiently. An improperly sized or installed liner can lead to dangerous conditions, including carbon monoxide poisoning. Following the manufacturer's instructions and adhering to local building codes are essential during the installation phase. After the insert is installed and inspected, understanding the specific model's operation is the next essential step.

Different wood-burning fireplace inserts can vary slightly in their operation. Always refer to the manufacturer's manual for detailed instructions specific to the model. There are some general guidelines for safely and efficiently operating a wood-burning insert. Selecting the right type of wood is the first crucial aspect to consider.

Selecting and Preparing Wood

The type and quality of wood used in a fireplace insert significantly impact its performance and the safety of the system. Seasoned hardwood is the recommended fuel source. Seasoning refers to the drying process, which reduces the moisture content of the wood. Green or freshly cut wood can contain up to 50% moisture, leading to inefficient burning, increased creosote buildup in the chimney, and reduced heat output. Creosote is a flammable residue formed from unburned wood particles and gases, and its accumulation can cause chimney fires.

Hardwoods, such as oak, maple, ash, and birch, are denser than softwoods like pine or fir. This density allows them to burn longer and produce more heat. Softwoods, while easier to ignite, burn more quickly and produce more smoke and creosote. Avoid burning treated wood, painted wood, or any wood containing preservatives, as these materials release harmful chemicals into the air when burned.

Seasoning wood requires splitting it and stacking it in a manner that allows for adequate air circulation. A sunny and windy location is ideal for drying wood. Generally, hardwood requires at least six months to a year of seasoning to reach an acceptable moisture content (below 20%). Using a moisture meter to check the wood's moisture content is a reliable way to ensure it is adequately seasoned. The wood should be stored off the ground to prevent moisture absorption from the soil. Covering the top of the woodpile will protect it from rain and snow while still allowing for air circulation.

Properly sized firewood is also crucial. Wood that is too large may be difficult to ignite and burn incompletely. Wood that is too small may burn too quickly. The optimal size for most fireplace inserts is typically between 16 and 20 inches in length, but this can vary depending on the insert model. The pieces should be split to a manageable size, typically 4 to 6 inches in diameter. Consistent sizing promotes even and efficient burning.

Starting and Maintaining a Fire

Starting a fire in a wood-burning fireplace insert requires a specific technique to establish a good draft and ensure clean burning. The "top-down" or "upside-down" fire starting method is often recommended for its efficiency and reduced smoke production. To utilize this method, begin by placing the largest pieces of wood at the bottom of the firebox, arranged in a tight, parallel pattern. Then, layer smaller pieces of wood on top, perpendicular to the larger pieces. Finally, place kindling and a fire starter on top of the uppermost layer.

This method allows the fire to burn down gradually, minimizing the release of smoke and gases. As the fire burns, it heats the chimney, creating a strong draft that pulls air through the insert and promotes complete combustion. Avoid using excessive amounts of paper or flammable liquids to start the fire, as this can create a dangerous flare-up. Commercial fire starters, such as wax-based logs or fire starter sticks, are a safer and more effective alternative.

Once the fire is established, adjust the air controls to regulate the burning rate. Most fireplace inserts have primary and secondary air controls. The primary air control regulates the air entering the firebox from below, while the secondary air control regulates the air entering from above, which helps to burn off smoke and gases. Start with the air controls fully open to establish a strong fire, and then gradually reduce them once the wood is burning well. The goal is to achieve a steady, controlled burn with minimal smoke. Overly restricting the airflow can lead to smoldering, smoke production, and creosote buildup.

Maintaining the fire involves adding wood as needed to maintain a consistent heat output. Add wood to the back of the firebox, leaving space for air to circulate around the logs. Avoid overloading the firebox, as this can restrict airflow and lead to incomplete combustion. Rake the coals forward periodically to ensure that the fire burns evenly. Regularly check the chimney draft to ensure that it is functioning properly. A strong, upward draft is essential for efficient and safe operation.

Ash removal is another crucial aspect of fire maintenance. Excess ash can accumulate in the firebox, reducing airflow and hindering the burning process. Allow the ashes to cool completely, preferably overnight, before removing them. Use a metal shovel and a metal container to remove the ashes. Never use a vacuum cleaner to remove ashes, as they may contain hot embers that can ignite the vacuum cleaner bag. Dispose of the ashes in a safe location away from flammable materials. A small layer of ash can be left in the firebox to insulate the coals and promote better burning.

Safety and Maintenance

Safety is the paramount consideration when operating a wood-burning fireplace insert. Carbon monoxide (CO) is a colorless, odorless, and deadly gas produced by incomplete combustion. Install carbon monoxide detectors in the home, especially near sleeping areas, and test them regularly. Ensure that the detectors are functioning properly and have fresh batteries.

Creosote buildup is another significant safety hazard. Schedule annual chimney inspections and cleanings by a certified chimney sweep. Regular inspections can identify potential problems, such as cracks in the chimney liner or excessive creosote buildup. Cleaning the chimney removes creosote, reducing the risk of chimney fires. The frequency of chimney cleaning depends on the amount of wood burned and the type of wood used, but at a minimum, an annual inspection is recommended.

Always keep a fire extinguisher readily accessible near the fireplace insert. Ensure that everyone in the household knows how to use the fire extinguisher. Have a plan in place in case of a fire, including evacuation routes and a designated meeting point outside the home.

Regular maintenance of the fireplace insert itself is also essential. Inspect the door gasket for any signs of wear or damage. A damaged gasket can allow air to leak into the firebox, reducing efficiency and increasing the risk of smoke leakage. Replace the gasket as needed. Check the glass door for cracks or chips. A damaged glass door can compromise the integrity of the firebox and should be replaced promptly.

Inspect the air controls regularly to ensure that they are functioning properly. Lubricate the moving parts of the air controls as needed to prevent them from sticking. Clean the heat exchanger surfaces of the insert periodically to remove soot and ash buildup. This buildup can reduce the insert's efficiency and heat output. Use a wire brush or a specialized chimney cleaning tool to clean the heat exchanger surfaces.

By following these guidelines for selecting and preparing wood, starting and maintaining a fire, and ensuring safety and maintenance, one can maximize the heating potential of a wood-burning fireplace insert while minimizing the risks associated with its use. Regular inspection, cleaning, and adherence to the manufacturer's instructions are crucial for long-term safe and efficient operation.

Wood Burning Fireplace Inserts 1 Stove Insert Dealer

Why A Wood Burning Fireplace Insert Bethesda Md Service

Wood Inserts We Love Fire

Why A Wood Burning Fireplace Insert Bethesda Md Service

Ventis Hei240 Wood Burning Insert

Lopi Premium Wood Fireplace Inserts Custom Hearth Fireplaces And Stoves

Wood Burning Fireplace Inserts Insert Installation

Fireplace Insert Installation Wood Burning Inserts

.aspx?strip=all)

Cost Of Operating A Wood Insert Cord Calculator Regency

Why Put A Wood Insert Inside Fireplace Maple Mtn

Related Posts