How to Remove a Fireplace Damper Door

The fireplace damper door, also known as the damper plate, is a critical component within a fireplace system. Its primary function is to seal the chimney flue when the fireplace is not in use, preventing heat loss from the home and keeping out unwanted elements such as rain, snow, and animals. Over time, damper doors can become damaged due to rust, corrosion, or mechanical failure, necessitating their removal for repair or replacement. Understanding the correct procedures for safely removing a damper door is essential for maintaining the efficiency and safety of a home's fireplace system.

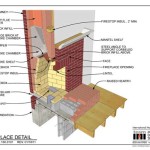

The process of removing a damper door can vary depending on the specific type of damper installed and its method of attachment. Common damper types include throat dampers, top-mount dampers, and cast iron dampers. Each type presents unique challenges and requires specific tools and techniques for successful removal. Before commencing any work, it is imperative to identify the damper type and thoroughly inspect the surrounding area for any potential hazards, such as loose bricks or crumbling mortar.

Safety is paramount when working with fireplace components. Prior to starting the removal process, ensure the fireplace is completely cold. It is advisable to wear safety glasses and gloves to protect against debris and potential sharp edges. Good ventilation is also important, as working inside a fireplace can stir up dust and soot. A dust mask or respirator may be necessary, especially if the existing damper door is heavily corroded or contains asbestos (although asbestos dampers are uncommon and should only be handled by qualified professionals).

This article outlines a general approach to removing a fireplace damper door. However, due to the diversity of fireplace designs, always consult the manufacturer's instructions or a qualified chimney sweep if uncertainty exists regarding the specific procedure for a given fireplace system. Furthermore, it is crucial to have a replacement damper or a plan for sealing the flue after the old damper is removed to prevent heat loss and unwanted airflow.

Key Point 1: Identifying the Damper Type and Attachment Method

The first step in removing a fireplace damper door is to accurately identify the type of damper and how it is attached to the fireplace structure. This will inform the tools and techniques required for safe and effective removal. There are primarily three common types of dampers:

1.

Throat Dampers:

These are the most common type and are located directly above the firebox in the throat of the fireplace. They typically consist of a metal plate that pivots open and closed, controlled by a handle or lever. Throat dampers are often attached with bolts, screws, or rivets.2.

Top-Mount Dampers:

Also known as chimney-top dampers, these are installed at the top of the chimney flue. They offer a tighter seal than throat dampers and help to prevent heat loss more effectively. Top-mount dampers are typically attached with screws or clamps to the chimney liner.3.

Cast Iron Dampers:

These are typically found in older fireplaces and are more robust than sheet metal dampers. They generally consist of a large cast iron plate that pivots on a central axis. Cast iron dampers are often attached with bolts or pins.Once the damper type has been identified, the method of attachment must be determined. This may involve a visual inspection using a flashlight to examine the hinges, pivot points, and any visible fasteners. Look for screws, bolts, rivets, or welds. If rust or corrosion obscures the attachment points, use a wire brush to carefully clean the area and reveal the underlying hardware.

Document the attachment method with photographs or sketches to aid in reassembly or installation of a replacement damper. This documentation can also be helpful when seeking advice from a chimney sweep or fireplace professional.

Key Point 2: Gathering the Necessary Tools and Materials

Having the correct tools and materials on hand before commencing the removal process will ensure a smooth and efficient operation. The specific tools required will depend on the damper type and its attachment method, but a general list includes:

1.

Safety Glasses and Gloves:

Essential for protecting eyes and hands from debris and sharp edges.2.

Dust Mask or Respirator:

Protects against inhaling dust, soot, and potentially harmful particles.3.

Screwdrivers (various sizes and types):

Phillips head and flathead screwdrivers are commonly needed to remove screws.4.

Wrenches (various sizes):

Used to remove nuts and bolts. A socket set may also be helpful.5.

Pliers (needle-nose and standard):

Useful for gripping and manipulating small parts.6.

Wire Brush:

Used to clean rust and corrosion from fasteners and hinges.7.

Penetrating Oil:

Helps to loosen rusted or corroded fasteners. Allow it to soak for several hours or overnight for best results.8.

Hammer:

May be needed to gently tap stubborn fasteners or loosen corroded parts.9.

Chisel or Punch:

Can be used to break free stubborn rivets or pins.10.

Reciprocating Saw or Angle Grinder (with metal cutting blade):

May be required to cut through rusted or seized fasteners or to cut the damper plate itself if it is heavily damaged and cannot be removed through other means. Use caution when using power tools inside the fireplace, ensuring adequate ventilation and protecting surrounding surfaces from sparks.11.

Shop Vacuum:

For cleaning up dust and debris after the removal process.12.

Drop Cloth or Protective Covering:

To protect the floor surrounding the fireplace from debris and scratches.In addition to these tools, have a container available to collect removed parts and fasteners to keep the work area organized and prevent loss of small components.

Key Point 3: The Removal Process and Potential Challenges

Once the damper type has been identified, the attachment method determined, and the necessary tools gathered, the actual removal process can begin. The following is a general guide, but remember to adapt the steps based on the specific characteristics of the fireplace.

1.

Preparation:

Spread a drop cloth around the fireplace to protect the floor. Put on safety glasses, gloves, and a dust mask or respirator. Open windows or doors to provide adequate ventilation.2.

Loosening Fasteners:

Apply penetrating oil to any rusted or corroded screws, bolts, or rivets. Allow the oil to soak for several hours or overnight if possible. Use a wire brush to clean away excess rust and debris.3.

Removing Fasteners:

Use the appropriate screwdriver or wrench to carefully remove the fasteners. If a fastener is severely rusted or seized, try applying heat with a propane torch (exercise extreme caution) or use a bolt extractor. Avoid excessive force, which can strip the fastener head or break the fastener itself.4.

Detaching the Damper Plate:

Once all fasteners have been removed, gently try to detach the damper plate from its hinges or pivot points. If the plate is stuck, try tapping it gently with a hammer. If necessary, use a chisel or punch to break free any remaining corrosion or debris.5.

Removing a Stuck Damper:

One common challenge is dealing with a damper that is completely stuck due to rust or corrosion. In such cases, more aggressive methods may be required. A reciprocating saw or angle grinder with a metal cutting blade can be used to cut through the damper plate or its hinges. This should be done with extreme caution to avoid damaging the surrounding fireplace structure and to protect oneself from sparks and flying debris. Alternatively, a professional chimney sweep can be consulted for their expertise and specialized tools.6.

Dealing with a Broken Handle:

If the damper handle is broken or seized, it may need to be cut off or removed before the damper plate can be detached. Pliers or a bolt cutter can be used to cut through the handle. If the handle is attached with a screw or bolt, try to remove it using the appropriate tool.7.

Cleaning and Inspection:

After the damper door has been removed, thoroughly clean the area around the damper opening using a shop vacuum and wire brush. Inspect the surrounding bricks and mortar for any signs of damage or deterioration. Address any necessary repairs before installing a replacement damper.8.

Disposal:

Safely dispose of the old damper door and any associated debris. Metal components can often be recycled. If the damper contains asbestos (unlikely, but possible in very old installations), it should be handled as hazardous waste and disposed of according to local regulations. Seek professional assistance from a qualified asbestos abatement contractor.By following these steps and taking necessary precautions, the fireplace damper door can be successfully removed, paving the way for repair, replacement, or flue sealing. Remember, safety is paramount, and professional assistance should be sought if uncertainty exists at any point in the process.

How To Fix A Stuck Fireplace Damper The Blog At Fireplacemall

Removing A Fireplace Damper For Chimney Liner Installation Rockford

Fireplace Damper Removal For Chimney Sweeping

Chimney Damper Repair Fix A Broken

How To Open Fireplace Damper The Blog At Fireplacemall

How To Fix A Stuck Fireplace Damper Dummies

Cutting Out A Damper And Knocking Some Blocks Firewood Ders Club

Everything You Need To Know About Chimney Dampers All Pro Service

How To Repair A Broken Fireplace Damper Doityourself Com

Fireplace Damper Removal For Chimney Sweeping

Related Posts