How To Reface a Brick Fireplace With Wood

A brick fireplace, while often charming, can sometimes feel outdated or clash with a new design aesthetic. Refacing a brick fireplace with wood offers a relatively straightforward method to dramatically alter the look of a living space, adding warmth, texture, and a touch of personalized style. This process involves careful planning, precise measurements, and diligent execution to ensure the finished product is both aesthetically pleasing and structurally sound. Refacing is often preferred over demolition and rebuilding, as it is less disruptive, less expensive, and can often be completed in a shorter timeframe.

Before commencing the project, it's crucial to thoroughly assess the existing brick fireplace. This evaluation should include checking for structural integrity, identifying any loose or crumbling bricks, and ensuring that the fireplace meets current building codes. Addressing any underlying issues before applying the wood refacing is paramount to prevent future problems that could compromise the integrity of both the fireplace and the new wooden facade. This assessment also involves determining the desired aesthetic outcome. Considerations should include the type of wood to be used, the style of the wood paneling or trim, and the overall impact on the room's decor.

Planning and Preparation are Key

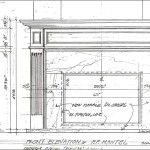

The success of a fireplace refacing project hinges on meticulous planning and thorough preparation. This phase involves detailed measurements, material selection, and the acquisition of necessary tools and safety equipment. Accurate measurements of the fireplace's dimensions are essential for calculating the amount of wood needed and for creating precise cuts. It is advisable to create a detailed sketch or blueprint of the planned design, including the placement of each wooden component. This visual aid will serve as a valuable reference throughout the project and help to minimize errors.

Material selection plays a significant role in the final appearance and durability of the refaced fireplace. The choice of wood should be based on several factors, including its aesthetic properties, its resistance to heat and moisture, and its overall cost. Hardwoods such as oak, maple, and cherry are popular choices due to their durability and attractive grain patterns. Softwoods like pine and cedar can also be used, but they may require additional treatment to enhance their resistance to heat and moisture. Consider using fire-retardant treated wood for added safety. Beyond the wood itself, other necessary materials include construction adhesive, screws or nails, wood filler, sandpaper, primer, and paint or stain.

Gathering the appropriate tools is also essential for efficient and accurate execution. A circular saw, miter saw, or table saw will be needed for cutting the wood to size. A drill or impact driver will be required for fastening the wood to the brick. A level, measuring tape, and square will be used for ensuring accuracy and alignment. Safety equipment, such as safety glasses, gloves, and a dust mask, should always be worn to protect against potential hazards.

Attaching the Wood to the Brick

The process of attaching the wood to the brick requires careful consideration of the chosen method. Direct adhesion using construction adhesive is a common approach, but it is crucial to ensure that the adhesive is compatible with both the wood and the brick. Mechanical fasteners, such as screws or nails, can provide a more secure attachment, especially for heavier wood panels. However, this method requires pre-drilling pilot holes through the wood and into the brick, which can be a time-consuming and challenging task.

Before applying any adhesive or fasteners, the surface of the brick must be thoroughly cleaned and prepared. Remove any loose debris, dirt, or paint using a wire brush or scraper. Consider applying a bonding agent to the brick surface to improve adhesion. When using construction adhesive, apply it evenly to the back of the wood panel and press it firmly against the brick. Use shims or spacers to maintain consistent spacing between the panels and to ensure proper alignment. Allow the adhesive to cure completely according to the manufacturer's instructions.

If using screws or nails, pre-drill pilot holes through the wood panel and into the brick using a masonry drill bit. Choose screws or nails that are long enough to penetrate the brick sufficiently to provide a secure hold. When driving the fasteners, be careful not to overtighten them, as this could damage the wood or the brick. Recess the head of the screws or nails slightly below the surface of the wood, and then fill the holes with wood filler to create a smooth, seamless finish.

Special attention should be paid to areas around the firebox opening. These areas are exposed to higher temperatures and require additional precautions. Consider using fire-resistant materials, such as a non-combustible backer board, behind the wood paneling. Maintain a safe distance between the wood and the firebox opening to prevent the wood from overheating or catching fire. This distance should comply with local building codes and regulations. The installation may also involve building a wood frame around the opening before applying the panels.

Finishing Touches and Safety Considerations

Once the wood refacing is complete, the final step involves applying finishing touches to enhance the appearance and protect the wood. This includes sanding, filling any gaps or imperfections, and applying a primer and paint or stain. Sanding smooths the surface of the wood and removes any rough edges or splinters. Use progressively finer grits of sandpaper to achieve a smooth, even finish. Fill any gaps or imperfections with wood filler, and allow it to dry completely before sanding it smooth.

Applying a primer is essential for preparing the wood surface for paint or stain. Primer helps to create a uniform surface, improves adhesion, and prevents the paint or stain from being absorbed unevenly. Choose a primer that is compatible with the type of wood and the chosen finish. Apply the primer evenly and allow it to dry completely according to the manufacturer's instructions. Afterwards, apply the desired paint or stain in thin, even coats, allowing each coat to dry completely before applying the next.

Safety considerations are paramount throughout the entire refacing process. Always wear appropriate safety gear, including safety glasses, gloves, and a dust mask. Ensure adequate ventilation when working with adhesives, paints, or stains. Follow the manufacturer's instructions for all materials and tools. When working with power tools, be sure to read and understand the safety instructions. Inspect the fireplace regularly for any signs of damage or wear. Address any issues promptly to prevent them from escalating into more serious problems.

In addition to the construction process, it is important to remember the ongoing safety surrounding fireplace use. Always have the fireplace professionally inspected before using it for the first time after refacing. Make sure the chimney is clean and free of obstructions. Use seasoned firewood to minimize smoke and creosote buildup. Never leave a fire unattended, and always extinguish it completely before leaving the room or going to bed. Install and maintain smoke detectors and carbon monoxide detectors to provide early warning of potential hazards. Adhering to these safety precautions will ensure that the refaced fireplace provides years of enjoyment and warmth while maintaining a safe and comfortable living environment.

The selection of wood finishes can also greatly affect safety surrounding the fireplace. Some paints and stains are more flammable than others. Therefore, when choosing finishes, it is best to opt for those that are specifically designed for use near heat sources. Fire-retardant coatings can provide an extra layer of protection, further minimizing the risk of fire. Before applying any finish, research its properties and ensure that it is appropriate for the intended use. Similarly, when selecting construction adhesives, choose those that are non-flammable and low-VOC (volatile organic compound) to reduce the risk of toxic fumes and fire hazards.

How To Cover A Brick Fireplace With Wood Stone Nina Hendrick Home Remodel Diy

Reface A Fireplace With The Look Of Stone Or Brick Barron Designs

:max_bytes(150000):strip_icc()/MadetobeaMommaBefore-5bb2476446e0fb002607ad4f.jpg?strip=all)

Before And After Fireplace Makeovers

How To Build A Fireplace Surround Beneath My Heart

Our Transformed Fireplace Before After Reface Diy Update

Diy Fireplace Makeover Wood Slat

16 Red Brick Fireplace Makeover Ideas

How To Cover A Brick Fireplace With Wood Stone Nina Hendrick Home

Diy Fireplace Makeover Wood Slat

How I Refaced My 1970 S Brick Fireplace Easily And Inexpensively

Related Posts