How to Build a Rumford Fireplace: A Comprehensive Guide

The Rumford fireplace, named after Sir Benjamin Thompson, Count Rumford, is a design lauded for its efficiency and radiant heat output. Unlike traditional fireplaces, the Rumford fireplace is characterized by its shallow firebox and angled fireback, designed to maximize heat reflection into the room. Its taller opening also contributes to a better draft, minimizing smoke spillage. Constructing a Rumford fireplace is a specialized task that requires careful planning, precise execution, and a thorough understanding of masonry principles. This article outlines the key steps involved in building a Rumford fireplace, providing a guideline for experienced masons and individuals with advanced construction skills.

Before commencing any construction, verifying compliance with local building codes and obtaining necessary permits is crucial. Fireplace construction is regulated to ensure safety and prevent fire hazards. Consult local authorities to ascertain specific requirements regarding chimney height, clearances from combustible materials, and structural integrity.

Planning and Design Considerations

The initial stage of building a Rumford fireplace involves meticulous planning and design. This includes determining the fireplace's dimensions, selecting appropriate materials, and calculating the chimney size. A well-designed Rumford fireplace not only provides efficient heating but also enhances the aesthetic appeal of the room.

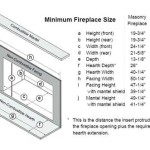

Determining Fireplace Dimensions: Rumford fireplaces typically have a wider opening than they are deep. A common rule of thumb is to make the opening height slightly larger than the depth. The overall size of the fireplace should be proportionate to the room it will heat. Online resources and specialized books offer sizing charts and guidelines to assist in selecting appropriate dimensions based on room size and desired heat output.

Material Selection: Firebrick, a type of refractory brick designed to withstand high temperatures, is the primary material for the firebox. Common brick or concrete blocks are typically used for the surrounding structure and chimney. The choice of facing material, such as stone, brick, or tile, will influence the aesthetic of the finished fireplace. Mortar used in fireplace construction must also be heat-resistant. Type N mortar is often recommended for chimney construction, while a specialized refractory mortar is required for the firebox.

Chimney Sizing: The chimney's size and height are critical for proper draft and smoke evacuation. A chimney that is too small will not draw adequately, resulting in smoke spillage into the room. A chimney that is too large may cool too quickly, leading to downdrafts. Most Rumford fireplace designs suggest a chimney flue area that is approximately one-tenth the area of the fireplace opening. The chimney should extend at least three feet above the roofline and two feet above any part of the building within ten feet.

Throat Design: The throat is the area where the firebox transitions into the smoke chamber. In a Rumford fireplace, the throat is typically narrow and angled to create a smooth flow of smoke into the chimney. The throat's design is crucial for preventing downdrafts and ensuring efficient smoke removal.

Foundation and Hearth Construction

A solid and level foundation is paramount for any fireplace. The foundation must be capable of supporting the considerable weight of the fireplace structure. The hearth, the area in front of the fireplace opening, serves as a protective barrier against sparks and embers. It should extend a sufficient distance into the room, as specified by local building codes.

Foundation Preparation: The foundation should be poured concrete, reinforced with steel rebar. The dimensions of the foundation should be slightly larger than the footprint of the fireplace. Verify that the foundation is level and properly cured before commencing construction.

Hearth Construction: The hearth typically consists of a non-combustible material, such as brick, stone, or tile, laid over a concrete base. There are two types of hearths: a raised hearth and a flush hearth. A raised hearth is elevated above the floor level, while a flush hearth is level with the floor. Building codes typically specify minimum hearth extension requirements to protect combustible flooring materials from sparks and embers. These requirements often depend on the fireplace opening's size.

Building the Ash Dump: Many fireplaces incorporate an ash dump, a small opening in the hearth that allows ashes to be swept into an ash pit below. The ash pit should be accessible for cleaning and should be lined with firebrick or concrete blocks.

Building the Firebox and Smoke Chamber

The firebox is the heart of the Rumford fireplace, where the fire burns. The smoke chamber is the area above the firebox that collects smoke and funnels it into the chimney. Precise construction of these components is essential for optimal performance.

Firebox Construction: The firebox is constructed using firebrick and refractory mortar. The firebrick should be laid in a running bond pattern, ensuring that joints are staggered for added strength. The fireback is typically angled forward at approximately 45 degrees to reflect heat into the room. The side walls of the firebox are also slightly angled to further enhance heat reflection. It is important to use a consistent mortar joint thickness throughout the firebox. Consult a Rumford fireplace design guide for precise dimensions and angles.

Creating the Rumford Throat: The Rumford throat is formed by carefully shaping the firebox opening and the area immediately above it. The throat should be narrow and smooth, with a slight arc shape. This design creates a venturi effect, accelerating the flow of smoke into the smoke chamber. This is a critical area for proper draw and requires careful attention to detail.

Smoke Chamber Construction: The smoke chamber is constructed using common brick or concrete blocks. The walls of the smoke chamber should be sloped inward to create a funnel shape, directing smoke upward into the chimney. The transition from the firebox to the smoke chamber should be gradual and smooth to minimize turbulence. The interior of the smoke chamber should be parged with a smooth layer of refractory mortar to seal any cracks and create a more efficient flow of smoke. The angle and design of the smoke chamber is critical in creating a proper draft and eliminating any back pressure from smoke.

Chimney Construction

The chimney is the final component of the fireplace system, responsible for exhausting smoke and combustion gases away from the building. Proper chimney construction is crucial for safety and performance.

Chimney Materials: Chimneys are typically constructed from brick, concrete blocks, or a combination of both. The chimney should be lined with a flue liner, which is a ceramic or metal tube that protects the chimney structure from the corrosive effects of flue gases. Flue liners are available in various sizes and shapes to match the chimney's dimensions. The size of the flue is related to the size of the fireplace opening, typically around 1/10 the dimensions of the opening.

Chimney Height and Clearance: The chimney should extend at least three feet above the roofline and two feet above any part of the building within ten feet. This ensures that the chimney is tall enough to create a sufficient draft and prevents downdrafts caused by nearby obstructions. Proper clearance from combustible materials is essential to prevent fire hazards. Consult local building codes for specific clearance requirements.

Chimney Cap Installation: A chimney cap is a protective covering that prevents rain, snow, and debris from entering the chimney. It also helps to prevent downdrafts and improve draft performance. Chimney caps are available in various styles and materials. Some chimney caps also incorporate spark arrestors, which prevent embers from escaping the chimney and potentially igniting nearby vegetation. A properly installed chimney cap can help prevent costly chimney repairs in the future.

Mortar Considerations: Type N mortar is typically used for chimney construction above the roofline, as it is more resistant to weathering than other types of mortar. The mortar joints should be carefully struck to create a watertight seal and prevent water penetration. Repointing mortar joints as needed is essential to maintain the chimney's structural integrity.

Constructing a Rumford fireplace is a complex project that demands a high level of skill and attention to detail. While this guide provides a comprehensive overview of the key steps involved, it is essential to consult with experienced professionals and adhere to all applicable building codes and safety regulations.

Rumford Fireplace Plans Instructions

Rumford Fireplace Plans Instructions

Rumford Fireplace Plans Instructions

Rumford Fireplace Plans Instructions

Rumford Fireplace Plans Instructions

Rumford Fireplace Plans Instructions

Rumford Plans And Instructions Superior Clay

What Is A Rumford Fireplace And Why It S Better Than Your The Craftsman Blog

Instructions Certified Buckley Rumford Fireplace

Build A Fireplace Brick By Fine Homebuilding