How To Build A Fireplace Insert Frame

Installing a fireplace insert can be a significant upgrade, improving heating efficiency and aesthetics. However, many existing fireplaces require an appropriately sized and structurally sound frame to accommodate the insert. Building a custom frame ensures a perfect fit, optimal performance, and enhanced safety. This article provides a detailed guide on how to construct a fireplace insert frame.

Planning and Preparation

The initial phase involves meticulous planning and accurate measurements. The accuracy of the frame is paramount for the safe and efficient operation of the fireplace insert. Before commencing any physical construction, it is crucial to determine the specific requirements of the insert being installed. This includes consulting the manufacturer's specifications, particularly regarding minimum clearances to combustible materials and the required opening dimensions.

Start by thoroughly measuring the existing fireplace opening. Note the height, width, and depth of the firebox. Pay attention to any irregularities or obstructions within the firebox that might affect the frame dimensions. It is essential to account for any discrepancies and adjust the frame design accordingly. These measurements will directly impact the dimensions of the frame and ensure a secure and appropriate fit. Consider the weight of the insert, as this will influence the material selection and the structural integrity required of the frame.

Next, based on the fireplace insert manufacturer's specifications, determine the minimal clearances. The frame must maintain the specified distances from any combustible materials in the vicinity of the fireplace. Failure to comply with these clearances can lead to a fire hazard. These clearances often vary depending on the material used for the frame construction and the insulation properties inherent to the insert itself.

Select appropriate materials for the frame construction. Steel is generally preferred due to its strength, durability, and resistance to high temperatures. The gauge of the steel will depend on the weight of the insert and the overall size of the frame. Consult with a qualified professional to determine the optimal steel gauge for the specific application. Consider the local building codes and regulations, which might stipulate specific materials and construction methods. It is sometimes necessary to use non-combustible framing materials such as cement board, especially in zones where the insert has very small clearance requirements.

Frame Construction

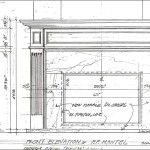

This stage involves cutting, welding, and assembling the frame components. Prior to cutting any materials, double-check all measurements and ensure that the frame design adheres to the manufacturer's specifications and local building codes. Prepare a detailed cutting list to minimize waste and ensure accuracy.

Cut the steel according to the cutting list. Use a metal-cutting saw or a plasma cutter for precise cuts. Ensure the edges are deburred to prevent injuries and ensure a smooth welding surface. Clean the steel thoroughly to remove any rust, oil, or other contaminants that could compromise the weld quality. Proper surface preparation is essential for achieving strong and reliable welds.

Assemble the frame components according to the planned design. Secure the pieces together using welding techniques. Ensure each weld is strong and complete. Use appropriate welding techniques, such as MIG or TIG welding, depending on the steel gauge and desired weld quality. Wear appropriate safety gear, including a welding helmet, gloves, and protective clothing. The welding process requires precision and skill. Tack-weld the pieces together first to verify alignment before completing the final welds. Check for squareness and levelness throughout the welding process.

Reinforce the frame, particularly at the corners. Reinforcement can be achieved by welding additional steel pieces or using gussets. Pay special attention to areas that will bear the weight of the insert. The reinforcement should be strategically placed to distribute the load evenly and prevent any deformation of the frame over time. The size and type of reinforcement will depend on the dimensions of the frame and the weight of the insert.

Installation and Finishing

Once the frame is constructed, it must be properly installed within the fireplace opening. This involves securing the frame to the existing firebox structure. The method of securing the frame will depend on the construction of the firebox. Options include bolting, welding, or using masonry anchors. Ensure the frame is plumb and level before permanently securing it. Any misalignment can affect the performance and lifespan of the insert.

Before installing the insert, consider the finishing aspects of the frame. Remove any sharp edges or burrs. Apply a heat-resistant paint or coating to protect the steel from corrosion and enhance its aesthetic appeal. Choose a paint or coating specifically designed for high-temperature applications. Follow the manufacturer's instructions for application. Allow the paint or coating to fully cure before installing the insert.

Install non-combustible materials lining the frame. This provides an extra layer of protection against heat transfer to combustible materials. Confirm that the chosen material is approved for use around fireplaces and meets all local building codes. Cement board is a common choice for this purpose. Attach the material securely to the frame using appropriate fasteners. Ensure there are no gaps or voids that could allow heat to escape.

Finally, install the fireplace insert according to the manufacturer's instructions. Ensure the insert is properly seated within the frame and securely fastened. Make all necessary connections for gas, electricity, or venting, as applicable. Verify the insert is operating correctly and safely before using the fireplace. A professional inspection is recommended to ensure the installation meets all safety requirements.

Building a fireplace insert frame requires careful planning, precise execution, and adherence to safety guidelines. This detailed guide provides the necessary information to construct a safe and functional frame, ensuring the efficient and safe operation of the fireplace insert.

Diy Fireplace With Electric Insert Angela Marie Made

How To Build A Diy Built In Fireplace With An Electric Insert The Creative Mom

How To Diy Built In Electric Fireplace Jenna Sue Design

Diy Fireplace With Electric Insert Angela Marie Made

Diy Fireplace With Electric Insert Angela Marie Made

How To Build A Diy Built In Fireplace With An Electric Insert The Creative Mom

Easy How To Build A Diy Fireplace With An Electric Insert Design

Easy How To Diy An Electric Fireplace Surround Design Build

Diy Modern Fireplace Designed Simple

How To Build A Diy Stone Fireplace Boxwood Design Co

Related Posts