High Heat Paint: Protecting and Beautifying Your Fireplace

Fireplaces, whether wood-burning, gas, or electric, are often a central feature in homes, providing warmth and ambiance. However, the high temperatures generated by these appliances can take a toll on their surfaces, leading to discoloration, rust, and even structural damage. High heat paint is a specialized coating designed to withstand these extreme conditions, offering both protection and aesthetic enhancement for fireplace components.

This article explores the properties, applications, and selection criteria for high heat paint used on fireplaces, focusing on the essential aspects of this protective coating. It also addresses surface preparation, application techniques, safety considerations, and maintenance strategies to ensure the longevity and performance of the painted surface.

Understanding High Heat Paint Properties

High heat paint differs significantly from standard paints due to its unique formulation. These paints are designed to resist degradation when exposed to elevated temperatures, which can range from several hundred to over 1000 degrees Fahrenheit, depending on the specific product. The key properties that contribute to the heat resistance of these paints include:

Pigment Composition: Standard paints utilize pigments that can break down, discolor, or even emit harmful fumes when heated. High heat paints, however, employ specialized pigments, often metallic or ceramic-based, that maintain their color and structural integrity at high temperatures. Examples include aluminum, zinc, and various metal oxides. These pigments also contribute to the paint's ability to reflect heat, further minimizing its absorption and potential damage.

Resin System: The resin, or binder, in paint is responsible for adhering the pigment to the surface and forming a durable film. Ordinary resins cannot withstand extreme heat, becoming brittle, cracking, or vaporizing. High heat paints use resins formulated from silicone, epoxy, or modified acrylic polymers that are specifically engineered to maintain their flexibility and adhesion at high temperatures. These resins are also resistant to chemical degradation and oxidation, further extending the life of the coating.

Additives and Solvents: Additional additives, such as stabilizers, anti-corrosion agents, and flow modifiers, are incorporated into the paint to enhance its performance and application characteristics. The solvents used in high heat paints are selected for their ability to evaporate quickly and cleanly, leaving behind a durable and heat-resistant film. Low-VOC (volatile organic compound) formulations are increasingly available, minimizing environmental impact and improving indoor air quality.

Temperature Rating: High heat paints are rated by their maximum continuous operating temperature. It is crucial to select a paint with a temperature rating that exceeds the maximum temperature expected from the fireplace surface. Using a paint with an inadequate temperature rating will result in premature failure of the coating, potentially leading to corrosion and other damage.

Durability and Adhesion: Beyond heat resistance, high heat paints must also exhibit good durability and adhesion to the substrate. The paint film should be resistant to chipping, scratching, and abrasion. Proper surface preparation is essential to ensure adequate adhesion, as contaminants such as rust, grease, and loose paint can compromise the bond between the paint and the surface.

Applications of High Heat Paint on Fireplaces

High heat paint is used on various components of fireplaces, each serving a specific purpose in protecting and enhancing the appliance. The primary applications include:

Firebox Interior: The interior of the firebox, which directly contacts the flames and hot embers, is subjected to the highest temperatures. High heat paint is used to protect the metal surfaces from oxidation and corrosion, extending the lifespan of the firebox. Black high heat paint is commonly used in fireboxes for its ability to absorb and radiate heat efficiently, improving the overall performance of the fireplace.

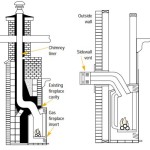

Stove Pipes and Flue Liners: Stove pipes and flue liners are responsible for venting combustion gases away from the fireplace. These components can reach high temperatures, especially during extended periods of use. High heat paint prevents rust and corrosion on the exterior of the stove pipes and flue liners, ensuring their structural integrity and preventing dangerous leaks of carbon monoxide gas. Various colors are available to match the aesthetic of the surrounding room.

Fireplace Doors and Frames: The doors and frames of fireplaces, while not directly exposed to flames, are still subjected to significant heat. High heat paint protects these components from discoloration, blistering, and rust, maintaining their appearance and functionality. It also enhances the overall aesthetic of the fireplace, contributing to the room's décor.

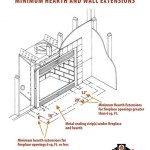

Exterior Surfaces: In some cases, the exterior surfaces of the fireplace, such as the surround or the chimney breast, may be painted with high heat paint. This is particularly relevant for fireplaces constructed from metal or materials that are prone to heat damage. The paint provides an extra layer of protection against heat-induced cracking or warping.

Grates and Accessories: Fireplace grates, andirons, and other accessories are often coated with high heat paint to protect them from the corrosive effects of heat and ash. This also helps them maintain their appearance and prevent rust from forming, which can be unsightly and weaken the metal.

Selecting the Right High Heat Paint

Choosing the appropriate high heat paint for a fireplace application requires careful consideration of several factors. Selecting the correct product will ensure optimal performance and longevity of the coating.

Temperature Rating: The first and most critical factor is the temperature rating of the paint. It must be higher than the maximum temperature the surface will reach during normal fireplace operation. Consulting the fireplace manufacturer's specifications or measuring the surface temperature with a non-contact infrared thermometer can help determine the appropriate temperature rating.

Type of Fireplace: Wood-burning fireplaces generally produce higher temperatures than gas or electric fireplaces. Therefore, wood-burning fireplaces require paints with higher temperature ratings. The specific type of fireplace also influences the choice of color and finish, as certain colors may be better suited for specific aesthetics.

Substrate Material: The type of material being painted, such as steel, cast iron, or brick, affects the adhesion and performance of the paint. Some high heat paints are formulated for specific substrates, while others are suitable for multiple materials. Consulting the paint manufacturer's specifications or a surface preparation guide can help determine the appropriate product.

Color and Finish: High heat paints are available in a variety of colors and finishes, ranging from matte black to metallic silver. The choice of color and finish is largely a matter of personal preference, but it is important to consider the overall aesthetic of the fireplace and the surrounding room. Matte finishes are often used in fireboxes to maximize heat absorption, while metallic finishes are used on exterior surfaces for decorative purposes.

Application Method: High heat paints can be applied using various methods, including aerosol spray, brush, and roller. The choice of application method depends on the size and complexity of the surface being painted, as well as the user's skill and experience. Aerosol sprays are convenient for small or intricate areas, while brushes and rollers are suitable for larger, flat surfaces.

Environmental Considerations: Selecting low-VOC high heat paints can reduce environmental impact and improve indoor air quality. These paints contain fewer harmful solvents and emit fewer fumes during application and curing. This is especially important in enclosed spaces, such as homes with fireplaces.

Reputation and Reviews: Checking the reputation and reading reviews of different brands and products can help make an informed decision. Online retailers and home improvement forums often provide valuable insights into the performance and durability of various high heat paints.

Surface Preparation and Application Techniques

Proper surface preparation is paramount to ensure optimal adhesion and longevity of high heat paint. Neglecting this step can lead to premature failure of the coating, regardless of the quality of the paint. The following steps are essential for preparing fireplace surfaces for painting:

Cleaning: Thoroughly clean the surface to remove dirt, dust, grease, soot, and other contaminants. Use a wire brush or scraper to remove any loose rust or scale. A degreasing agent may be necessary to remove stubborn grease or oil. Rinse the surface with clean water and allow it to dry completely.

Sanding: Sanding the surface creates a slightly rough texture that promotes better adhesion of the paint. Use sandpaper with a medium grit (e.g., 120-180) to lightly sand the surface, followed by a fine grit (e.g., 220-320) to smooth out any imperfections. Remove sanding dust with a tack cloth or vacuum.

Priming (Optional): In some cases, a high heat primer may be necessary to improve adhesion and prevent rust from bleeding through the paint. Consult the paint manufacturer's specifications to determine if priming is recommended. Apply the primer in a thin, even coat and allow it to dry completely before applying the topcoat.

Masking: Mask off any areas that should not be painted, such as glass doors or surrounding surfaces. Use painter's tape or masking paper to create clean lines and prevent overspray.

Application: Apply the high heat paint in thin, even coats, following the manufacturer's instructions. Avoid applying too much paint in a single coat, as this can lead to runs, drips, and uneven drying. Allow each coat to dry completely before applying the next. Multiple thin coats are generally better than one thick coat.

Curing: After the final coat has been applied, allow the paint to cure completely. Curing times vary depending on the type of paint and the ambient temperature, but typically range from 24 to 72 hours. Avoid using the fireplace during the curing period, as this can damage the paint film.

Safety Considerations and Maintenance

Working with high heat paints requires adherence to safety precautions to prevent injury and ensure a safe working environment:

Ventilation: Work in a well-ventilated area to avoid inhaling harmful fumes. If working indoors, open windows and doors to provide adequate air circulation. Use a respirator mask to protect your lungs from paint fumes and dust.

Protective Gear: Wear protective clothing, gloves, and eye protection to prevent contact with the paint. Avoid getting paint on your skin or in your eyes. If contact occurs, wash thoroughly with soap and water.

Flammability: High heat paints often contain flammable solvents. Keep away from open flames, sparks, and other sources of ignition. Store paints in a cool, dry place away from heat and sunlight.

Disposal: Dispose of used paint cans and rags properly, following local regulations. Do not pour paint down the drain or into the environment.

Maintenance: Regular maintenance can help prolong the life of the high heat paint coating. Clean the painted surfaces periodically with a soft cloth and mild detergent. Avoid using abrasive cleaners or scouring pads, as these can scratch or damage the paint film. Touch up any areas that show signs of chipping or peeling promptly to prevent further deterioration.

By understanding the properties, applications, selection criteria, application techniques, safety considerations, and maintenance strategies associated with high heat paint, individuals can effectively protect and beautify their fireplace surfaces, ensuring years of reliable performance and aesthetic appeal.

Use Fireplace Paint To Update Old Hardware For A Makeover

How To Paint A Brick Fireplace Living With Lady

Use Fireplace Paint To Update Old Hardware For A Makeover

Updating A Fireplace With High Heat Paint Thrifty Decor Diy And Organizing

Best Heat Resistant Paint For Fireplace Top High Paints

High Temperature Paint

High Temperature Stove Fireplace Color Paint Brick Anew

Fireplace Makeover With High Heat Spray Paint

Fireplace Makeover Spray Paint Magic

How To Paint The Inside Of A Fireplace Simple Upgrade Maria Louise Design

Related Posts