High Efficiency Wood Burning Fireplace Inserts: A Comprehensive Guide

Wood burning fireplace inserts have emerged as a popular solution for homeowners seeking to improve the efficiency and functionality of their existing fireplaces. Traditional open fireplaces, while aesthetically pleasing, are notorious for their energy inefficiency, often drawing warm air from the home and expelling it up the chimney. High-efficiency wood burning fireplace inserts address this issue by providing a closed combustion system that significantly reduces heat loss and maximizes the amount of heat radiated into the living space. These inserts are designed to fit directly into an existing fireplace opening, transforming it into a powerful and efficient heating appliance.

The core principle behind a high-efficiency wood burning fireplace insert lies in its controlled combustion process. Unlike open fireplaces that allow for uncontrolled airflow, inserts regulate the air supply, ensuring a cleaner and more complete burn. This results in less smoke, creosote buildup, and ultimately, more usable heat. Modern inserts often incorporate features like secondary combustion and catalytic combustors to further enhance efficiency and reduce emissions.

Understanding the Mechanics of High Efficiency

A high-efficiency wood burning fireplace insert operates through a system designed to optimize the burning process and maximize heat transfer. The process generally involves several key steps:

1. Air Intake and Control: The insert draws air into the combustion chamber, typically through adjustable vents. These vents allow the user to control the air supply, influencing the burn rate and heat output. Some models feature automatic air control systems that adjust the air intake based on the fire's temperature and oxygen levels.

2. Primary Combustion: This is the initial burning phase where the wood is ignited and begins to release volatile gases. Inefficient fireplaces often lose a significant portion of these gases up the chimney without being fully burned. High-efficiency inserts, however, contain these gases within the firebox.

3. Secondary Combustion: This is a crucial aspect of high-efficiency models. Unburned gases from the primary combustion are channeled into a secondary combustion chamber, where they are mixed with preheated air and ignited. This secondary burn significantly reduces emissions and extracts additional heat from the fuel.

4. Catalytic or Non-Catalytic Combustion: Some inserts utilize a catalytic combustor, a ceramic honeycomb coated with a catalyst (typically platinum or palladium). The catalyst lowers the ignition temperature of the gases, allowing them to burn more completely at a lower temperature. Non-catalytic models achieve secondary combustion through careful design of the firebox and air intake systems to create the necessary high-temperature environment.

5. Heat Exchange: The heat generated from the combustion process is transferred to the living space through various methods. Many inserts feature a convection system, where a fan circulates air around the firebox, distributing warm air into the room. Radiant heat also contributes to the overall heating effect. The design of the firebox and heat exchanger maximizes the surface area for heat transfer.

6. Exhaust System: High-efficiency inserts require a properly installed chimney liner to safely vent the exhaust gases. The liner is typically made of stainless steel and is sized to match the insert's flue outlet. A properly sized and installed liner ensures proper draft and prevents the buildup of creosote.

The Benefits of Choosing a High Efficiency Insert

Investing in a high-efficiency wood burning fireplace insert offers numerous advantages over traditional open fireplaces, including increased energy efficiency, reduced emissions, and improved heating performance. The quantifiable benefits make this a compelling option for heating homes and reducing reliance on expensive fuel sources.

1. Increased Energy Efficiency: The primary benefit of a high-efficiency insert is its ability to deliver significantly more heat to the living space compared to an open fireplace. Traditional fireplaces often have efficiency ratings as low as 10-20%, meaning that the vast majority of the heat generated is lost up the chimney. High-efficiency inserts, on the other hand, can achieve efficiency ratings of 70-80% or higher, meaning that a much larger proportion of the heat is radiated into the room. This translates to lower heating bills and a more comfortable living environment.

2. Reduced Emissions: The controlled combustion process in high-efficiency inserts results in significantly lower emissions of particulate matter, carbon monoxide, and other pollutants. This is due to the more complete burning of wood and gases, which minimizes the amount of unburned fuel that is released into the atmosphere. The reduced emissions contribute to cleaner air quality and a more environmentally friendly heating solution. Many high-efficiency inserts meet the stringent emission standards set by the Environmental Protection Agency (EPA).

3. Improved Heating Performance: High-efficiency inserts are capable of heating larger areas more effectively than open fireplaces. The closed combustion system and efficient heat transfer mechanisms allow the insert to produce a consistent and controlled heat output. Many models feature variable speed blowers that can be used to circulate warm air throughout the room, ensuring even heating. The ability to control the heat output also allows for more precise temperature regulation.

4. Enhanced Safety: Open fireplaces can pose a safety risk due to sparks, embers, and the potential for chimney fires. High-efficiency inserts provide a safer heating alternative by containing the fire within a closed firebox. This reduces the risk of sparks escaping into the room and minimizes the buildup of creosote in the chimney, which is a major cause of chimney fires. The controlled combustion process also reduces the risk of carbon monoxide poisoning.

5. Cost Savings: While the initial investment in a high-efficiency wood burning fireplace insert may be higher than that of an open fireplace, the long-term cost savings can be substantial. The increased energy efficiency results in lower heating bills, and the reduced emissions can qualify for tax credits or rebates in some areas. The reduced risk of chimney fires can also save on maintenance and repair costs. Furthermore, by supplementing or replacing a primary heating system with a wood-burning insert, homeowners can reduce their reliance on expensive fossil fuels.

Factors to Consider When Choosing an Insert

Selecting the right high-efficiency wood burning fireplace insert requires careful consideration of various factors to ensure that it meets the specific needs of the homeowner and the characteristics of the existing fireplace. Ignoring key factors can lead to dissatisfaction and reduced performance.

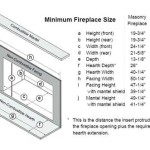

1. Heating Capacity and Size: It is crucial to choose an insert with a heating capacity that is appropriate for the size of the area to be heated. Heating capacity is typically measured in British Thermal Units (BTUs) per hour. A larger area will require an insert with a higher BTU output. Similarly, the physical dimensions of the insert must be compatible with the size of the existing fireplace opening. Accurate measurements of the fireplace opening are essential to ensure a proper fit. Consider the firebox size, as this dictates the length of wood that can be burned.

2. Efficiency Rating: The efficiency rating of the insert is a key indicator of its performance. Look for inserts with a high efficiency rating (70% or higher) to maximize heat output and minimize fuel consumption. The efficiency rating is typically provided by the manufacturer and is often certified by independent testing laboratories. Understanding the testing methodology is helpful in interpreting the efficiency rating.

3. Emissions Certification: Ensure that the insert meets the emission standards set by the Environmental Protection Agency (EPA). EPA-certified inserts produce significantly lower levels of particulate matter and other pollutants. Choosing an EPA-certified insert contributes to cleaner air quality and may qualify for tax credits or rebates. Check the EPA database for certified models.

4. Catalytic vs. Non-Catalytic: Consider the advantages and disadvantages of catalytic and non-catalytic inserts. Catalytic inserts generally offer higher efficiency and lower emissions, but they require periodic replacement of the catalytic combustor. Non-catalytic inserts are simpler in design and require less maintenance, but they may not be as efficient or clean-burning as catalytic models. The lifespan and cost of replacement for catalytic combustors should be factored into the decision.

5. Features and Options: Evaluate the features and options offered by different insert models. Some inserts feature automatic air control systems, variable speed blowers, and remote controls. These features can enhance convenience and improve the overall heating experience. Consider the availability of accessories such as hearth extensions, trim kits, and chimney liners. The aesthetic design of the insert should also be considered to ensure that it complements the style of the home.

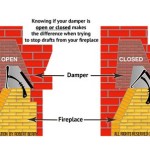

6. Installation and Chimney Liner: Proper installation is critical to the safe and efficient operation of a high-efficiency wood burning fireplace insert. It is essential to have the insert installed by a qualified professional who is familiar with local building codes and regulations. A properly sized and installed chimney liner is also essential to ensure proper draft and prevent the buildup of creosote. Consult with a chimney professional to determine the appropriate size and type of liner for the insert and the existing chimney.

7. Fuel Type and Availability: While all are wood burning inserts, consider the type and availability of wood in your area. The moisture content of the wood is also a critical factor. Burning seasoned wood (wood that has been air-dried for at least six months) is essential for efficient combustion and reduced emissions. Green or wet wood will produce more smoke and creosote.

Wood Burning Fireplace Inserts Insert Installation

The Best Wood Burning Fireplace Inserts Or Stoves Ecohome

Osburn Stratford Ii Zero Clearance Wood Stove Fireplace Woodland Direct

Hi500 Hybrid Catalytic Cast Iron Wood Burning Insert By Regency

Our S High Efficiency Fireplaces Valcourt

Regency Hampton Hi500 Wood Insert Fireplace S Hearth Home

Energy Efficient Wood Burning Fireplaces

T25i Timberwolf Wood Fireplace Insert Hearth Stove Patio

Why A Wood Burning Fireplace Insert Bethesda Md Service

Clydesdale Hearthstone Stoves

Related Posts