Hearth Fireplace Stone: Aesthetics, Functionality, and Installation

Hearth fireplace stone serves as a critical component in both the aesthetic design and functional safety of a fireplace. The stone selected for this application withstands high temperatures, protects combustible materials surrounding the fireplace opening, and contributes significantly to the overall architectural style of the room. Understanding the various types of hearth fireplace stone, their properties, and the proper installation techniques is essential for achieving a visually appealing and structurally sound fireplace.

The term "hearth" refers specifically to the non-combustible floor area directly in front of and within the fireplace opening. This area is designed to prevent sparks, embers, and hot materials from igniting nearby carpets, flooring, or furniture. The specific dimensions of the hearth are dictated by building codes and are dependent on the size of the fireplace opening. A properly sized and constructed hearth ensures the safe operation of the fireplace by providing a fire-resistant barrier.

Fireplace stone, in the context of hearth construction, encompasses a range of materials that are naturally fire-resistant and durable. These materials include, but are not limited to, granite, slate, marble, soapstone, and certain types of manufactured stone. The choice of stone depends on factors such as budget, desired aesthetic, the level of heat resistance required, and the structural considerations of the surrounding fireplace structure.

Types of Hearth Fireplace Stone

Several types of natural and manufactured stone are commonly used for hearth fireplaces, each offering distinct advantages and disadvantages. Understanding these differences is crucial for selecting the appropriate material for a specific fireplace project.

Granite: Granite is an igneous rock known for its exceptional hardness, durability, and heat resistance. It is available in a wide range of colors and patterns, making it a versatile choice for various design styles. Granite is relatively non-porous, making it resistant to staining and easy to clean. Its high density allows it to withstand significant weight and impact, making it suitable for high-traffic areas. The cost of granite can vary depending on the rarity and availability of specific colors and patterns.

Slate: Slate is a metamorphic rock characterized by its fine-grained texture and natural clefting, which creates a distinctive layered appearance. It is naturally fire-resistant and relatively durable. Slate is often chosen for its rustic and earthy aesthetic. While slate is less porous than some other natural stones, it can be susceptible to scratching and chipping. Regular sealing can help protect the surface and maintain its appearance. Slate typically offers a more budget-friendly option than granite or marble.

Marble: Marble is a metamorphic rock prized for its elegant appearance and distinctive veining patterns. It is available in a vast array of colors and finishes. While marble is heat-resistant, it is more porous and less durable than granite. It is more susceptible to staining and etching from acidic substances. Marble requires a protective sealant to prevent damage and regular cleaning to maintain its pristine condition. Marble is often considered a luxury option due to its higher cost and maintenance requirements.

Soapstone: Soapstone is a metamorphic rock composed primarily of talc, giving it a soft, smooth texture. It is known for its exceptional heat retention properties, making it an efficient material for absorbing and radiating heat. Soapstone is naturally non-porous, resistant to staining, and relatively easy to maintain. It is often used in fireplaces and wood stoves due to its ability to withstand extreme temperatures and thermal shock. Soapstone develops a natural patina over time, adding to its character and charm.

Manufactured Stone: Manufactured stone, also known as cultured stone or faux stone, is a composite material made from cement, aggregates, and pigments. It is designed to replicate the appearance of natural stone at a lower cost. Manufactured stone offers a wide range of styles and textures, allowing for a variety of design options. While generally fire-resistant, the specific fire rating of manufactured stone varies depending on the manufacturer and composition. It is important to select a manufactured stone product that is specifically designed for fireplace applications and meets relevant safety standards.

Functionality and Safety Considerations

The primary function of hearth fireplace stone is to provide a non-combustible barrier that protects surrounding materials from heat and sparks. Choosing a stone with adequate heat resistance and installing it according to building codes is crucial for ensuring the safe operation of the fireplace.

Heat Resistance: Different types of stone have varying levels of heat resistance. It is essential to select a stone that can withstand the high temperatures generated by a fireplace without cracking, warping, or deteriorating. Granite, slate, soapstone, and certain types of manufactured stone are all suitable choices for hearth fireplaces. The specific heat rating and thermal properties of the stone should be considered when making a selection.

Hearth Dimensions and Building Codes: Building codes specify the minimum dimensions for the hearth, which vary depending on the size of the fireplace opening. The hearth must extend a certain distance in front of the fireplace and to the sides to adequately protect combustible materials. Compliance with local building codes is essential for ensuring the safety and legality of the fireplace installation. Failure to meet these requirements can result in fines or require costly modifications.

Non-Combustible Materials: The hearth must be constructed entirely of non-combustible materials. This includes not only the stone but also the underlying support structure and any mortar or grout used in the installation. Combustible materials, such as wood framing or plywood, must be kept a safe distance from the fireplace opening to prevent the risk of fire. Fire-resistant backer boards and insulation can be used to provide additional protection.

Spark Arrestor: A spark arrestor is a screen or mesh that covers the fireplace opening to prevent sparks and embers from escaping. Using a spark arrestor can significantly reduce the risk of fire caused by flying embers. The spark arrestor should be properly sized to fit the fireplace opening and regularly inspected for damage or blockages.

Installation Techniques and Best Practices

Proper installation is critical for ensuring the functionality, safety, and longevity of the hearth fireplace stone. Following best practices and adhering to manufacturer's instructions are essential for achieving a successful installation.

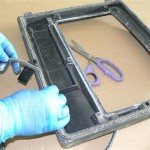

Substrate Preparation: The substrate, or underlying surface, must be clean, level, and structurally sound. Any existing flooring or combustible materials must be removed. A layer of cement board or concrete backer board should be installed to provide a stable and fire-resistant base for the hearth stone. The substrate should be properly primed and leveled to ensure a smooth and even surface.

Mortar and Grout Selection: Using a high-quality, heat-resistant mortar is crucial for bonding the hearth stones together. The mortar should be specifically designed for use with stone and capable of withstanding high temperatures without cracking or crumbling. The grout used to fill the joints between the stones should also be heat-resistant and compatible with the mortar. Pre-mixed mortars and grouts are available for convenience, but it is important to choose products that meet the specific requirements of the fireplace installation.

Stone Placement and Leveling: The hearth stones should be carefully placed and leveled to create a smooth and even surface. A level should be used to ensure that each stone is properly aligned and that there are no gaps or uneven areas. Spacers can be used to maintain consistent joint widths between the stones. The mortar should be applied evenly to the back of each stone, and the stones should be pressed firmly into place.

Sealing and Maintenance: After the mortar and grout have cured, the hearth stone should be sealed with a penetrating stone sealer. The sealant helps to protect the stone from staining and moisture damage. The sealer should be applied according to the manufacturer's instructions. Regular cleaning and maintenance are essential for preserving the appearance and longevity of the hearth fireplace stone. Spills should be cleaned up promptly, and the stone should be periodically cleaned with a mild detergent and water. Avoid using abrasive cleaners or harsh chemicals, as these can damage the stone's surface.

By carefully considering the type of stone, functionality, safety, and installation techniques, a durable, safe, and aesthetically pleasing hearth fireplace can be achieved, providing warmth and adding value to the home.

Professional Stonework Stone Fireplace Surround Hearths

Warm Up This Winter With A Natural Stone Fireplace

Stone Fireplace Ideas Hearth Slab Wrought Iron And Glass Doors Remodel

A Stonehouse York Reclaimed Stone Hearth Fireplaces

Stacked Stone Fireplace 10 Luxurious Design Ideas Stoneyard

Stone Fireplaces

Stone Hearth Fireplace Old World Stoneworks

Slabs Hearths Terrazzo Stone Supply A Siteone Company

Some Stone Fireplace Surround Ideas You Ll Love Southwest Supply

Stone Fireplaces Hearths Rockford

Related Posts