Understanding the Gas Fireplace Firebox: A Comprehensive Guide

The gas fireplace firebox is the heart of a gas fireplace system, the component where combustion occurs and heat is generated. It is a crucial element contributing to both the functionality and the aesthetic appeal of a gas fireplace. A thorough understanding of the firebox, its components, and its maintenance is essential for homeowners seeking efficient and safe operation of their gas fireplace.

The firebox serves as a controlled environment for burning gas, typically natural gas or propane, to produce heat. It is designed to safely contain the flames and direct the heat outward into the room. The firebox also provides a visually appealing display, often incorporating realistic-looking logs or other decorative elements to mimic the look of a traditional wood-burning fireplace. The construction and design of a firebox have a direct impact on the fireplace’s heating efficiency, safety, and overall lifespan.

The materials used in constructing a firebox are typically chosen for their ability to withstand high temperatures and resist corrosion. Common materials include heavy-gauge steel, cast iron, and refractory ceramic. These materials are strategically employed in different parts of the firebox to maximize heat retention and durability. The specific material composition and construction techniques will vary depending on the manufacturer and the intended use of the fireplace.

In addition to its structural function, the firebox plays a role in ensuring proper ventilation and exhaust of combustion byproducts. A well-designed firebox is integrated with the fireplace's venting system to efficiently remove carbon monoxide, water vapor, and other gases produced during combustion. Proper ventilation is paramount to ensure the safety of the occupants and to prevent damage to the surrounding structure.

Key Point: Construction Materials and Design Considerations

The materials utilized in the construction of a gas fireplace firebox are fundamental to its performance and longevity. Steel is often used for the main structure due to its strength and formability. However, steel alone may not be sufficient to withstand the sustained high temperatures within the firebox. Therefore, cast iron is frequently incorporated in areas exposed to the most intense heat, such as the grate and the back wall. Cast iron possesses excellent heat retention properties, allowing it to radiate heat more efficiently into the room.

Refractory ceramic materials are also common in firebox construction, particularly in the lining. These materials are highly resistant to thermal shock and can withstand extreme temperature fluctuations without cracking or degrading. They serve to insulate the firebox, preventing heat loss and protecting the surrounding structure from excessive heat exposure. The combination of these materials allows for a firebox that can endure the rigorous demands of continuous operation while maintaining optimal performance.

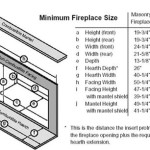

The design of the firebox also plays a critical role in its efficiency and safety. The size and shape of the firebox affect the airflow and combustion process. A properly designed firebox will promote complete combustion of the gas, minimizing the production of pollutants. The placement of the burner and the arrangement of the logs or decorative elements also impact the distribution of heat and the overall appearance of the flame.

Furthermore, the firebox design must account for proper venting. The flue or vent system must be appropriately sized and configured to ensure that combustion gases are safely and efficiently removed from the room. Backdrafting, where exhaust gases enter the living space, is a serious safety hazard and can be prevented with proper firebox and vent system design.

Key Point: Venting Systems and Safety Regulations

The venting system of a gas fireplace is inextricably linked to the firebox and its functionality. The primary purpose of the venting system is to safely remove combustion byproducts from the living space. These byproducts, including carbon monoxide, water vapor, and other gases, can be harmful or even deadly if allowed to accumulate indoors. The venting system must be properly installed and maintained to ensure that these gases are effectively exhausted to the outside.

There are several types of venting systems commonly used with gas fireplaces, each with its own advantages and disadvantages. Direct vent systems draw air from the outside for combustion and exhaust gases directly to the outside through a sealed vent. These systems are highly efficient and safe, as they prevent indoor air from being used for combustion and eliminate the risk of backdrafting. B-vent systems, also known as natural vent systems, use indoor air for combustion and rely on natural convection to exhaust gases through a vertical vent. These systems require careful installation to ensure proper draft and prevent backdrafting.

Vent-free systems, as the name suggests, do not require a vent. They are designed to burn gas so completely that the exhaust gases are considered safe for indoor use. However, vent-free systems are subject to strict regulations and are often prohibited in certain jurisdictions. They also require careful monitoring of indoor air quality and are not recommended for use in enclosed spaces or homes with poor ventilation.

Safety regulations regarding gas fireplace fireboxes and venting systems are stringent and vary depending on local building codes. These regulations typically specify the allowable materials for firebox construction, the minimum clearances from combustible materials, and the requirements for venting systems. It is crucial for homeowners to ensure that their gas fireplace installations comply with all applicable codes and regulations to ensure the safety of their homes and families. Regular inspections by qualified professionals are also recommended to identify and address any potential safety issues.

Key Point: Maintenance and Troubleshooting

Regular maintenance is essential for ensuring the safe and efficient operation of a gas fireplace firebox. Neglecting maintenance can lead to a variety of problems, including reduced heating efficiency, increased risk of carbon monoxide poisoning, and premature failure of the fireplace components. A proactive maintenance schedule can help to prevent these issues and extend the lifespan of the appliance.

A key element of gas fireplace maintenance involves cleaning the firebox and its components. Over time, dust, soot, and other debris can accumulate inside the firebox, reducing its efficiency and potentially obstructing the burner. The logs or decorative elements should also be cleaned periodically to remove any buildup of soot or carbon deposits. The glass door, if present, should be cleaned with a specialized glass cleaner to remove any smudges or streaks.

Inspecting the burner and gas lines is another important aspect of maintenance. The burner should be checked for any signs of corrosion, damage, or obstruction. The gas lines should be inspected for leaks, using a soapy water solution to identify any potential problem areas. Any leaks should be repaired immediately by a qualified professional. The pilot light should also be checked regularly to ensure that it is burning properly. A weak or flickering pilot light may indicate a problem with the gas supply or the burner.

Troubleshooting common problems with a gas fireplace firebox can often be done by the homeowner, but it is important to exercise caution and consult the manufacturer's instructions before attempting any repairs. Common issues include a pilot light that won't stay lit, a weak or uneven flame, and unusual noises coming from the fireplace. These problems can often be resolved by cleaning the burner, adjusting the gas pressure, or replacing worn-out components. However, any repairs involving the gas lines or other critical components should be performed by a qualified technician.

Furthermore, it’s important to consider the age of the firebox. Older models may lack modern safety features and efficiency improvements. Upgrading to a newer, more efficient model could result in energy savings and enhanced safety. When considering upgrading, it’s crucial to consult with a qualified professional to ensure proper installation and compliance with local codes.

Understanding the firebox of a gas fireplace is vital for safe and effective operation. Regular maintenance, proper venting, and careful attention to safety regulations can help ensure that the gas fireplace provides warmth and comfort for years to come.

What Is A Fireplace Firebox Full Service Chimney

What Is A Fireplace Firebox Full Service Chimney

Superior 36 Inch Vent Free Circulating Gas Firebox Vrt3536 North Country Fire

Superior 42 Inch Vrt3500 Series Vent Free Gas Fireplace Firebox

Procom Universal Ventless Firebox 170016 The Home Depot

Monessen 32 Inch Lo Rider Clean Face Vent Free Gas Fireplace Firebox

Fireplace Insert Guide Fireplaces Direct Learning Center

Superior Fireplaces 42 Vent Free Firebox Fine S Gas

What Is A Fireplace Firebox Full Service Chimney

Superior Vrt2542ws 42 Inch Firebox With Vent Free Gas Log Set