Understanding Gas Fireplace Clearances: A Comprehensive Guide

Gas fireplaces offer an efficient and aesthetically pleasing heating solution for residential and commercial spaces. However, ensuring the safe operation of a gas fireplace necessitates a thorough understanding of required clearances. These clearances, often stipulated in building codes and manufacturer specifications, dictate the minimum distances combustible materials must be from the fireplace unit and its venting system. Adhering to these guidelines minimizes the risk of fire hazards and ensures optimal performance.

Gas fireplace clearances are not arbitrary; they are based on extensive testing and engineering analysis. Heat generated by the fireplace, particularly from the firebox and vent, can ignite nearby combustible materials like wood, drywall, fabrics, and even some types of insulation if they are too close. Therefore, understanding and implementing the specified clearances is paramount for preventing fires and maintaining a safe living environment.

This article provides a comprehensive overview of gas fireplace clearances, covering various aspects, including front clearances, side clearances, top clearances, hearth extensions, and venting clearances. It will also explore the impact of different fireplace types (direct vent, vent-free, and B-vent) on clearance requirements and highlight the importance of consulting manufacturer instructions and local building codes.

Key Point 1: Defining and Interpreting Clearances: Front, Side, and Top

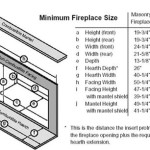

Understanding the different types of required clearances is crucial for proper gas fireplace installation. These clearances are usually measured from the fireplace appliance to the nearest combustible material. Key clearance types include front, side, and top clearances.

Front Clearance: This refers to the distance required between the front of the fireplace and any combustible materials. This is particularly important because the radiant heat produced by the flames often projects outwards. Items like furniture, rugs, curtains, and even wooden mantels must be kept far enough away to prevent them from overheating and potentially igniting. This clearance is usually the largest of the three mentioned, often ranging from 36 to 48 inches, depending on the fireplace model and heat output.

Side Clearance: Side clearances define the minimum distance between the sides of the fireplace and any adjacent walls or combustible materials. This clearance is essential for preventing heat buildup in the surrounding area. Side clearances are generally less stringent than front clearances but are still vital for safety. Typical values for side clearances can range from 6 to 12 inches, but this can vary based on the specific fireplace unit. Factors like the presence of a non-combustible facing material, such as brick or stone, can sometimes reduce the required side clearance.

Top Clearance: Top clearances dictate the distance between the top of the fireplace and any combustible materials overhead, such as a mantel, shelves, or even the ceiling. This is particularly important because hot air rises. Insufficient top clearance can lead to excessive heat accumulation, potentially causing the combustible material to char or ignite. Top clearances are dependent on the fireplace design, with some models requiring as little as 12 inches while others may necessitate 24 inches or more. The presence of a heat shield can sometimes reduce the required top clearance, but this must be specifically approved by the manufacturer and building codes.

Manufacturer instructions always provide the most accurate clearance specifications for a specific model. These are often presented in diagrams or tables detailing the minimum distances required for each clearance type. It is important to meticulously follow these specifications to ensure safe operation.

Furthermore, understanding how to measure these clearances accurately is crucial. Use a measuring tape to determine the distance from the surface of the fireplace appliance to the nearest combustible material. Always measure to the *nearest* point of the combustible material, not the average distance. Round up to the next inch if the measurement falls between two inch marks. Failure to observe these details could lead to hazardous conditions.

Key Point 2: Hearth Extensions and Floor Protection

Beyond the front, side, and top clearances, hearth extensions are another critical safety consideration. A hearth extension is a non-combustible surface that extends outwards from the front and sometimes the sides of the fireplace opening. The purpose of the hearth extension is to protect the combustible flooring underneath and in front of the fireplace from sparks, embers, and radiant heat.

The required size and material of the hearth extension are mandated by building codes and manufacturer instructions. Typical materials for hearth extensions include brick, stone, concrete, tile, and other non-combustible surfaces. It is crucial that the hearth extension is thick enough to provide adequate insulation and prevent heat from transferring to the combustible flooring below.

The dimensions of the hearth extension usually depend on the size and design of the fireplace. Building codes often specify minimum depths and widths for hearth extensions based on the firebox opening size and other factors. For instance, a larger fireplace with a wider opening will generally require a deeper hearth extension. The extension should also extend far enough to the sides of the fireplace opening to capture any sparks or embers that might escape.

The absence of a properly sized and constructed hearth extension can lead to combustible flooring materials, such as wood or carpet, overheating and potentially igniting. Even small sparks or embers can smolder unnoticed for extended periods, eventually leading to a fire. Therefore, adhering to the specified hearth extension requirements is crucial for preventing fires and protecting the surrounding structure.

In some cases, the fireplace itself may be listed for zero-clearance installation to combustible flooring, meaning a separate hearth extension is not required. This is usually indicated in the manufacturer's specifications. However, it is still advisable to confirm this with local building officials to ensure compliance with all applicable codes and regulations.

Key Point 3: Venting Clearances and System-Specific Requirements

The venting system of a gas fireplace is responsible for safely exhausting combustion gases, such as carbon monoxide and other harmful byproducts, to the outside. Proper venting is crucial for both safety and optimal fireplace performance. Venting clearances are critical to maintain the integrity of the venting system and prevent fire hazards. The type of venting system used (direct vent, B-vent, or vent-free) greatly impacts the required clearances.

Direct Vent Systems: These fireplaces use a sealed system that draws combustion air from outside and vents exhaust gases directly outside through a co-axial or concentric vent pipe. Because the venting system is sealed and the outer pipe often remains relatively cool, clearances to combustible materials are typically less restrictive compared to B-vent systems. However, clearances around the vent termination (the point where the vent exits the building) are still crucial. Manufacturer instructions will specify minimum distances from windows, doors, overhangs, and other building features to prevent exhaust gases from re-entering the building.

B-Vent Systems: These fireplaces utilize a B-vent gas vent pipe to exhaust combustion gases. B-vent pipes are not sealed and rely on natural draft to expel the gases. These vent pipes become much hotter than direct vent pipes, necessitating more stringent clearances to combustible materials. Typically, a minimum clearance of one inch is required between the B-vent pipe and any combustible materials throughout its entire length. This includes walls, ceilings, and framing members. Proper support and bracing of the B-vent pipe are also crucial to prevent it from coming into contact with combustible materials. Any penetration of a combustible wall or ceiling must be properly sealed using a listed firestop spacer to maintain the required clearance.

Vent-Free Systems: Although called “vent-free,” these systems still require careful planning. While they do not require a traditional venting system, they are designed to burn so cleanly that venting toxic gases is not necessary. Local codes heavily regulate these types of fireplaces and may limit their use. Vent-free fireplaces require ample room ventilation to prevent the buildup of moisture and byproducts of combustion. Clearances around the fireplace itself are still vital, similar to direct vent models, especially regarding top and front clearances.

Regardless of the venting system type, proper installation is paramount. Following the manufacturer's instructions explicitly is crucial to ensure that the venting system is installed correctly and that all required clearances are maintained. Any modifications to the venting system, such as extending or shortening the vent pipe or changing the type of vent pipe, must be approved by the manufacturer and comply with local building codes. Incorrectly installed venting systems can lead to dangerous carbon monoxide leaks, fires, and other safety hazards.

Regular inspection of the venting system is also essential. Check for any signs of damage, such as cracks, corrosion, or loose connections. Ensure that the vent termination is clear of obstructions, such as snow or debris. Any issues should be addressed promptly by a qualified technician to maintain the safety and efficiency of the fireplace.

In addition to these key points, factors like the BTUs (British Thermal Units) output of the appliance can significantly affect the specified clearances. Higher BTU output generally means higher temperatures and greater clearance requirements. Therefore, carefully consider the BTU rating of the fireplace when determining the appropriate clearances for a specific installation.

Consulting with a qualified gas fireplace installer and local building officials is always advisable to ensure compliance with all applicable codes and regulations. They can provide expert guidance on clearance requirements and venting specifications for a specific project, ensuring a safe and efficient installation. By understanding and adhering to these guidelines, homeowners can enjoy the warmth and ambiance of a gas fireplace while prioritizing safety and preventing potential hazards.

Mantel Clearance For Masonry Versus Manufactured Fireplaces

Enviro G42 Gas Zero Clearance Fireplace Fergus

Is A New Zero Clearance Fireplace Right For You Design Styles Sizes

Fireplace Insert Vs Zero Clearance Maple Mtn

Kingsman Hbzdv3624 Zero Clearance Direct Vent Gas Fireplace 36 Woodland

Comfortflame

.aspx?strip=all)

Zero Clearance Fireplaces Explained Regency Fireplace S

Zero Clearance Fireplaces Valor Gas

Fireplace Clearance Design Vancouver Gas Fireplaces

%20Clearances.jpg?strip=all)

Comfortflame