Full Masonry Fireplaces: A Comprehensive Overview

Full masonry fireplaces represent a traditional and enduring form of fireplace construction. Unlike factory-built fireplaces, which are typically composed of metal fireboxes and prefabricated chimneys, full masonry fireplaces are constructed entirely of brick, block, stone, or other approved masonry materials. This includes the firebox, smoke chamber, smoke shelf, and chimney, all built on-site by skilled masons. Their inherent durability and potential for architectural integration make them a popular choice for homeowners seeking a timeless and aesthetically pleasing heating solution.

The term "full masonry" emphasizes that the entire structure, from hearth to chimney crown, is crafted from masonry. This distinguishes it from fireplaces that might have a masonry veneer applied over a metal frame or utilize a prefabricated firebox insert. The defining characteristic is the complete reliance on masonry materials for both the structural integrity and heat-containment functions of the fireplace. The fireplace is more than just a heating appliance; it becomes an integral part of the home's structure.

A well-constructed full masonry fireplace offers several advantages, including superior thermal mass. Masonry materials absorb heat from the fire and slowly release it into the room, providing a more consistent and comfortable warmth compared to fireplaces with metal components. This radiative heat is often perceived as more pleasant than the forced-air heat of some modern systems. Moreover, the solid construction of a masonry fireplace can contribute to the overall structural stability of the building. Its substantial weight and interlocked construction can provide lateral support.

However, full masonry fireplaces also present certain challenges. The construction process is labor-intensive and requires specialized skills. This translates to a higher initial installation cost compared to prefabricated options. Furthermore, masonry fireplaces are heavy structures that require a robust foundation to support their weight. Careful planning and engineering are essential to ensure the fireplace is properly integrated into the building design and meets all applicable building codes.

The design of a full masonry fireplace is crucial to its performance and longevity. A properly designed firebox will maximize heat output and minimize smoke spillage. The smoke chamber, located above the firebox, should be carefully shaped to efficiently direct smoke into the chimney. The smoke shelf, a horizontal surface at the base of the smoke chamber, helps to prevent downdrafts from entering the firebox. The chimney itself must be sized correctly to create adequate draft, ensuring that smoke is effectively drawn out of the building.

The selection of materials for a full masonry fireplace is another important consideration. Firebrick, a type of refractory brick specifically designed to withstand high temperatures, is typically used for the firebox lining. The outer layers of the fireplace can be constructed from a variety of materials, including common brick, stone, or concrete block. The choice of materials will influence the overall appearance of the fireplace and its cost. It is important to select materials that are compatible with each other and that are appropriate for the local climate.

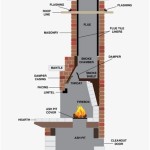

Key Point 1: Components and Functionality

A full masonry fireplace can be broken down into several critical components, each playing a distinct role in the fireplace's overall functionality. The firebox is the heart of the fireplace, where combustion occurs. Its proper construction, often employing firebrick, is essential for containing the extreme temperatures generated by the fire. Above the firebox sits the smoke chamber, which acts as a transition zone, funneling smoke and combustion gases from the firebox into the chimney. Integral to the smoke chamber is the smoke shelf. This horizontal projection is designed to intercept downdrafts and prevent them from entering the firebox, a critical function for maintaining a stable and efficient draft.

The chimney itself is a vertical conduit that draws smoke and exhaust gases upward and away from the living space. Its height and diameter are carefully calculated to ensure adequate draft. The top of the chimney is typically capped with a chimney crown, a concrete or masonry structure that protects the chimney from water infiltration and provides a finished appearance. The hearth, extending outward from the firebox opening, serves as a non-combustible surface that protects the floor from sparks and embers. Its size and configuration are often dictated by building codes.

Key Point 2: Construction Considerations

Building a full masonry fireplace is a complex undertaking that requires the expertise of a skilled mason. The process begins with a solid foundation, typically a concrete slab, designed to support the considerable weight of the structure. The dimensions and materials of the foundation must be carefully engineered to prevent settling and cracking. The mason then lays courses of brick, block, or stone, carefully mortaring each unit in place. Accurate measurements and precise alignment are essential to ensure the structural integrity and aesthetic appeal of the fireplace.

As the fireplace rises, the mason will incorporate various features, such as the firebox, smoke chamber, and chimney flue. Special attention must be paid to the details of these features to ensure they function properly. The firebox, for example, must be properly sized and shaped to promote efficient combustion. The smoke chamber must be smoothly tapered to facilitate the flow of smoke. The chimney flue must be lined with fireclay or other approved material to protect the masonry from the corrosive effects of combustion gases.

Building permits are typically required for the construction of a full masonry fireplace. These permits ensure that the fireplace meets all applicable building codes and safety standards. Inspections are typically conducted at various stages of the construction process to verify compliance. These inspections may include a foundation inspection, a framing inspection, and a final inspection.

Key Point 3: Design and Aesthetic Integration

Full masonry fireplaces offer unparalleled design flexibility, allowing homeowners to create a focal point that complements their home's architectural style. The choice of materials, such as brick, stone, or stucco, significantly impacts the fireplace's appearance. Brick provides a classic and timeless look, while stone can add a rustic or contemporary touch. Stucco offers a smooth and minimalist aesthetic.

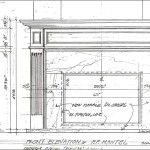

Beyond the materials, the design of the firebox opening, the mantel, and the chimney breast can be customized to suit individual preferences. The firebox opening can be arched, rectangular, or even custom-shaped. The mantel, a decorative shelf above the firebox opening, provides an opportunity to display artwork, family photos, or other decorative items. The chimney breast, the section of the fireplace that projects into the room, can be finished with a variety of materials and textures.

The size and scale of the fireplace should be carefully considered in relation to the size of the room. A large fireplace can overwhelm a small room, while a small fireplace may get lost in a large room. The fireplace should also be positioned in a location that maximizes its visual impact and its heating potential. A corner fireplace, for example, can provide warmth and ambiance to two adjacent rooms.

Masonry Vs Zero Clearance Thermo Rite Manufacturers

Temp Cast Indoor Masonry Fireplace And Oven Combo Patio Outdoor Furnishings

Masonry Fireplaces Or Metal Which Is Better Capo Artisan Series

How It Works Closer To The Hearth

Understanding The Anatomy Of A Fireplace Madewell Masonry

Masonry Fireplaces Installation Repair General Construction Inc

Appleton Fireplace Installation Services Ulman Masonry

Factory Built Fireplaces Vs Masonry

How To Build An Outdoor Fireplace

Masonry Fireplace Service Upgrade Hearth With A Surround