Forced Air Fireplace Insert: A Comprehensive Overview

Forced air fireplace inserts represent a significant upgrade to traditional fireplaces, offering increased heating efficiency and improved air circulation within a home. These inserts operate by drawing in cool room air, heating it through contact with the firebox, and then forcefully circulating the warmed air back into the living space using a fan or blower system. This method is considerably more effective than relying solely on radiant heat, which is characteristic of conventional fireplaces, resulting in a more consistent and comfortable temperature distribution throughout the room or even the entire house, depending on the insert's capacity and the home's ductwork.

The transition from an open fireplace to a forced air insert provides numerous advantages, including enhanced heat output, better energy efficiency, and reduced emissions. An open fireplace often loses a significant portion of its heat up the chimney, essentially acting as a net energy drain on the home. In contrast, a forced air insert is a closed system that captures and utilizes a larger percentage of the heat generated by the fire. This increased efficiency translates into lower heating costs and a reduced environmental impact.

Installation of a forced air fireplace insert typically involves inserting the unit into an existing fireplace opening and connecting it to a chimney liner. This process requires professional installation to ensure proper venting and safe operation. The chimney liner is critical for directing combustion byproducts safely out of the home and preventing dangerous gases, such as carbon monoxide, from entering the living space. Selecting the appropriate size and type of insert is also crucial for optimal performance and safety, considering factors such as the size of the room or area to be heated, the home's insulation levels, and local building codes.

Key Point 1: Enhanced Heating Efficiency and Air Circulation

The primary benefit of a forced air fireplace insert lies in its ability to dramatically improve heating efficiency compared to traditional fireplaces. Open fireplaces, while aesthetically pleasing, are notoriously inefficient, with much of the heat escaping through the chimney. Forced air inserts, however, are designed to capture and distribute a greater percentage of the heat generated by burning wood or other fuels.

The forced air mechanism is central to this enhanced efficiency. Cool air is drawn into the insert, typically from vents located at the bottom or sides of the unit. This air is then heated as it passes through the firebox, where it comes into direct contact with the hot surfaces surrounding the fire. A built-in blower or fan then forces the heated air out of the insert and into the room, effectively circulating warmth and preventing stratification, where hot air rises to the ceiling while the floor remains cold.

This forced air circulation ensures a more uniform temperature distribution throughout the room, creating a more comfortable and consistent heating experience. Furthermore, some forced air inserts can be connected to a home's existing ductwork, allowing for the distribution of heat to multiple rooms or even throughout the entire house. This whole-house heating capability makes forced air inserts a viable alternative or supplement to traditional central heating systems.

The level of heat output from a forced air fireplace insert is typically measured in British Thermal Units (BTUs). The appropriate BTU rating for a particular home depends on several factors, including the size of the space to be heated, the home’s insulation levels, and the climate. A correctly sized insert will provide sufficient heat to maintain a comfortable temperature without overworking the system or consuming excessive fuel.

Key Point 2: Fuel Options and Operational Considerations

Forced air fireplace inserts offer flexibility in terms of fuel options, with models available that burn wood, propane, natural gas, or even pellets. The choice of fuel depends on factors such as availability, cost, and homeowner preference. Wood-burning inserts are often favored for their traditional appeal and the readily available supply of wood in some regions. Propane and natural gas inserts offer convenience and ease of use, as they can be ignited with the push of a button and often feature thermostatic controls for maintaining a consistent temperature.

Pellet inserts utilize compressed wood pellets, which are a renewable and relatively clean-burning fuel source. Pellet stoves typically feature automatic fuel feeding systems, allowing for extended burn times and consistent heat output. Each fuel type has its own advantages and disadvantages, and the best choice depends on the individual homeowner’s needs and circumstances.

Operating a forced air fireplace insert requires adherence to safety guidelines and regular maintenance. For wood-burning inserts, it’s essential to use seasoned wood to minimize smoke and creosote buildup in the chimney. Creosote is a flammable substance that can accumulate in the chimney and pose a significant fire hazard. Regular chimney inspections and cleanings are crucial for preventing creosote buildup and ensuring safe operation.

Gas and propane inserts require professional installation and regular maintenance to ensure proper gas connections and burner operation. It’s important to have these units inspected annually by a qualified technician to check for leaks, ensure proper combustion, and maintain optimal performance. Pellet inserts also require regular cleaning and maintenance, including emptying the ash pan and cleaning the burn pot.

Regardless of the fuel type, it’s crucial to follow the manufacturer’s instructions for operating and maintaining the forced air fireplace insert. This includes proper venting, fuel storage, and safety precautions. Carbon monoxide detectors should be installed in the home to provide an early warning in the event of a gas leak or incomplete combustion.

Key Point 3: Installation, Maintenance, and Safety Protocols

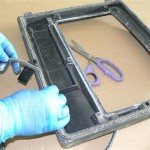

The installation of a forced air fireplace insert is a complex process that should be performed by a qualified professional. Improper installation can lead to safety hazards, such as carbon monoxide leaks or chimney fires. The installation process typically involves several steps, including preparing the fireplace opening, installing a chimney liner, connecting the insert to the chimney, and sealing any gaps to prevent air leaks.

The chimney liner is a critical component of the installation process, as it provides a safe and effective pathway for combustion byproducts to exit the home. The liner must be appropriately sized for the insert and made of a material that is compatible with the chosen fuel type. Stainless steel liners are commonly used for wood-burning inserts, while other materials may be suitable for gas or propane inserts.

Once the insert is installed, it’s essential to perform regular maintenance to ensure optimal performance and safety. This includes cleaning the firebox, inspecting the chimney, and checking for any signs of wear or damage. Wood-burning inserts require more frequent cleaning than gas or propane inserts due to the buildup of ash and creosote.

Safety protocols are paramount when operating a forced air fireplace insert. It’s crucial to keep flammable materials away from the insert and to never leave a fire unattended. Children and pets should be supervised around the unit to prevent accidental burns or injuries. Carbon monoxide detectors should be installed and tested regularly to provide an early warning in the event of a leak.

In addition to regular maintenance, it’s important to have the insert inspected annually by a qualified technician. This inspection can identify potential problems before they become serious and ensure that the unit is operating safely and efficiently. A professional inspection can also help to extend the lifespan of the insert and prevent costly repairs.

Selecting the right forced air fireplace insert involves careful consideration of several factors, including the size of the space to be heated, the desired fuel type, and the home’s existing chimney and ventilation system. Consulting with a qualified professional can help homeowners to make an informed decision and choose an insert that meets their specific needs and budget.

The efficiency and effectiveness of a forced air fireplace insert are also significantly influenced by the home's insulation. Proper insulation in walls, ceilings, and floors helps to retain heat and prevent drafts, reducing the amount of energy required to maintain a comfortable temperature. Upgrading insulation can further enhance the energy savings achieved by installing a forced air fireplace insert.

Finally, it's essential to research and comply with all local building codes and regulations regarding the installation and operation of fireplace inserts. These codes are designed to ensure safety and prevent hazards, such as chimney fires or carbon monoxide poisoning. Adhering to these regulations is not only required by law but also crucial for protecting the health and safety of the home's occupants.

Why A Wood Burning Fireplace Insert Bethesda Md Service

Moving Hot Air How To Heat Your House Using Fireplace

Ac01340 Forced Air Kit

Moving Hot Air How To Heat Your House Using Fireplace

Ventis Ds Ac01340 Forced Air Kit Use With Me300 He250r He275c Fireplaces Usa

Why A Wood Burning Fireplace Insert Bethesda Md Service

Wfp 75 Hearthstone Stoves

Air Filter King Fireplace Insert Corn Wood Pellet

Fireplace Insert Installation Step By Forbes Home

.aspx?strip=all)

Fireplaces That Work Without Power Be Storm Ready With Regency

Related Posts