Firerock Masonry Fireplace Kits: A Comprehensive Overview

Firerock Masonry Fireplace Kits offer a comprehensive solution for building aesthetically pleasing and structurally sound fireplaces. These kits provide pre-engineered components designed to simplify the construction process while maintaining the traditional look and performance of a masonry fireplace. This article provides a detailed overview of Firerock kits, their advantages, components, installation considerations, and design possibilities.

A key benefit of using Firerock kits is the reduction in on-site labor and the potential for faster project completion. The pre-engineered nature of the system minimizes the need for extensive cutting and fitting, streamlining the building process. This is particularly beneficial for contractors and homeowners seeking to efficiently construct a high-quality fireplace without the complexities and time constraints associated with traditional masonry methods.

Firerock's design considerations prioritize both aesthetic appeal and functional performance. Their fireplaces are designed to provide efficient heating while maintaining a classic, elegant appearance. The kits incorporate features designed to enhance combustion, minimize smoke spillage, and ensure safe operation. Additionally, the variety of design options available allows for customization to suit diverse architectural styles and homeowner preferences.

The core of the Firerock system lies in its lightweight concrete components. These components are manufactured to precise specifications, ensuring consistent quality and ease of assembly. The use of lightweight concrete reduces the overall weight of the fireplace, potentially simplifying structural support requirements and reducing the load on the foundation.

Key Advantages of Firerock Masonry Fireplace Kits

Firerock Masonry Fireplace Kits offer several key advantages over traditional masonry construction methods. These advantages include simplified construction, reduced labor costs, and consistent quality control. Understanding these benefits is crucial for making an informed decision about incorporating Firerock into a building project.

Simplified Construction: The pre-engineered nature of the Firerock system significantly simplifies the construction process. The kits contain all the necessary components, cut and shaped to precise dimensions. This eliminates much of the on-site cutting and fitting that is typically required with traditional masonry, reducing the risk of errors and speeding up the installation timeline. The included instructions provide clear guidance, making the process more manageable for both professional contractors and experienced DIY enthusiasts.

Reduced Labor Costs: By streamlining the construction process, Firerock kits can significantly reduce labor costs. The faster installation time translates directly into fewer man-hours required for the project. Moreover, the reduced need for specialized masonry skills can broaden the pool of qualified installers, potentially leading to more competitive labor rates. For homeowners undertaking the project themselves, the ease of installation can save substantial sums that would otherwise be spent on professional labor.

Consistent Quality Control: The manufacturing process for Firerock components ensures consistent quality and dimensional accuracy. Each component is produced to meet stringent specifications, minimizing variations and ensuring a uniform appearance. This is in contrast to traditional masonry, where variations in brick size, mortar consistency, and craftsmanship can lead to inconsistencies in the final product. The controlled manufacturing environment of Firerock promotes a high level of quality control, resulting in a durable and visually appealing fireplace.

Design Flexibility: Despite being a kit-based system, Firerock offers considerable design flexibility. While the core components are pre-engineered, the exterior of the fireplace can be customized with a variety of finishes, including brick, stone, stucco, and tile. This allows homeowners and designers to create a fireplace that seamlessly integrates with the overall aesthetic of the home. The availability of various hearth sizes, firebox openings, and chimney options further enhances the design possibilities.

Improved Performance: Firerock fireplaces are designed not only for aesthetics but also for optimal performance. The firebox design promotes efficient combustion, minimizing smoke production and maximizing heat output. The engineered chimney system ensures proper draft, preventing smoke spillage and improving overall efficiency. These performance features contribute to a safer and more enjoyable fireplace experience.

Components of a Firerock Masonry Fireplace Kit

A standard Firerock Masonry Fireplace Kit typically includes several key components, each designed to fulfill a specific function within the fireplace structure. Understanding these components is essential for proper installation and ensuring the long-term performance of the fireplace. These components generally encompass the firebox, smoke chamber, chimney components, and associated hardware.

Firebox: The firebox is the heart of the fireplace, where the fire burns. Firerock fireboxes are constructed from durable refractory concrete that can withstand the high temperatures of a wood-burning fire. The firebox is designed with specific dimensions to promote efficient combustion and maximize heat output. The kits often include pre-cut firebrick liners to further protect the firebox and enhance its thermal performance.

Smoke Chamber: The smoke chamber is located above the firebox and serves to collect and funnel smoke into the chimney. Firerock smoke chambers are designed with smooth, sloping walls to promote efficient smoke flow and minimize turbulence. This reduces the likelihood of smoke spillage and improves the overall drafting performance of the fireplace. The precisely engineered shape of the smoke chamber is critical for proper fireplace function and safety.

Chimney Components: The chimney is responsible for safely venting smoke and combustion gases away from the home. Firerock kits typically include a range of chimney components, such as flue liners, chimney blocks, and chimney caps. The flue liners are designed to protect the chimney structure from heat and corrosive gases, while the chimney blocks provide structural support and insulation. The chimney cap prevents rain, snow, and debris from entering the chimney.

Hearth Components: The hearth is the non-combustible area in front of the firebox opening. Firerock kits can include hearth extensions made from lightweight concrete or other non-combustible materials. These extensions provide a safe and aesthetically pleasing transition between the fireplace and the surrounding floor. The size and material of the hearth can be customized to suit the specific design of the fireplace.

Hardware and Accessories: In addition to the major components, Firerock kits also include various hardware and accessories necessary for installation. These may include mortar mix, anchoring hardware, and installation instructions. The instructions provide detailed step-by-step guidance on the proper assembly and installation of the fireplace. It is important to carefully review and follow these instructions to ensure a safe and successful installation.

Installation Considerations for Firerock Masonry Fireplace Kits

Proper installation is crucial for ensuring the safety, performance, and longevity of a Firerock Masonry Fireplace. While the kits are designed to simplify the construction process, careful planning and attention to detail are still essential. Several key considerations should be addressed before, during, and after installation.

Planning and Preparation: Before beginning the installation, it is important to carefully review the plans and specifications for the fireplace. Ensure that the location of the fireplace is suitable and that the structural support is adequate. Check local building codes and regulations to ensure compliance. Gather all necessary tools and materials, and familiarize yourself with the installation instructions.

Foundation and Structural Support: The foundation or subfloor must be capable of supporting the weight of the fireplace. Ensure that the foundation is level and properly sized. If the fireplace is being installed on an upper floor, consult with a structural engineer to determine the appropriate support requirements. The additional weight of the masonry fireplace needs to be properly accounted for in the building's structure.

Mortar Application: The mortar used for assembling Firerock components should be specifically designed for masonry fireplaces. Follow the manufacturer's instructions for mixing and applying the mortar. Ensure that the mortar joints are fully filled and properly tooled to create a watertight seal. Proper mortar application is essential for preventing leaks and maintaining the structural integrity of the fireplace.

Chimney Installation: The chimney must be installed according to the manufacturer's instructions and local building codes. Ensure that the chimney is properly aligned and supported. Use the correct type of sealant and flashing to prevent water penetration. The chimney should extend high enough above the roofline to ensure proper draft. A properly installed chimney is critical for venting smoke and combustion gases safely and efficiently.

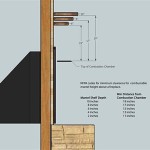

Clearances to Combustibles: Maintain proper clearances between the fireplace and any combustible materials, such as wood framing, drywall, and insulation. Follow the clearance guidelines specified in the installation instructions and local building codes. Improper clearances can create a fire hazard and should be strictly avoided.

Inspection and Testing: After the installation is complete, have the fireplace inspected by a qualified professional to ensure that it meets all safety requirements. Perform a draft test to verify that the chimney is drawing properly. Address any issues or concerns identified during the inspection before using the fireplace. A thorough inspection and testing process ensures the safe and efficient operation of the fireplace.

Design Possibilities with Firerock Masonry Fireplace Kits

Firerock Masonry Fireplace Kits offer a versatile platform for creating a wide range of fireplace designs. While the core components are pre-engineered, there is considerable flexibility in customizing the exterior appearance to suit different architectural styles and personal preferences. This creates opportunity for unique customization reflecting the tastes of the owner and the style of house.

Exterior Finishes: The exterior of the fireplace can be finished with a variety of materials, including brick, stone, stucco, and tile. These materials can be applied directly to the Firerock components, creating a seamless and integrated look. The choice of exterior finish will significantly impact the overall aesthetic of the fireplace.

Hearth Styles: The hearth can be customized in terms of size, shape, and material. A raised hearth can create a more dramatic focal point, while a flush hearth can provide a more minimalist look. The hearth can be finished with brick, stone, tile, or other non-combustible materials. The hearth style can be tailored to complement the overall design of the fireplace and the surrounding room.

Mantel Options: A mantel is a decorative shelf placed above the firebox opening. Firerock fireplaces can be fitted with a variety of mantel styles, ranging from simple wooden shelves to elaborate stone carvings. The mantel provides an opportunity to add a personal touch to the fireplace and create a focal point for the room.

Firebox Openings: Firerock offers various firebox opening options, including traditional rectangular openings, arched openings, and corner openings. The choice of firebox opening will impact the visual style of the fireplace and the way it interacts with the surrounding space. A corner fireplace can be a particularly effective way to maximize space and create a unique focal point.

Chimney Styles: The chimney can also be customized to complement the overall design of the fireplace. Options include brick chimneys, stone chimneys, and stucco chimneys. The chimney can be designed with various architectural details, such as corbels, caps, and decorative brickwork. The chimney style should be carefully considered to ensure that it complements the overall design of the home.

Incorporating Accents: Architectural accents such as niches, shelves, and decorative trim can be incorporated into the fireplace design to add visual interest and create a unique focal point. These accents can be integrated seamlessly with the Firerock components, creating a cohesive and well-designed fireplace. The use of accents allows for further personalization and customization of the finished product.

Firerock Kits Versa Lok Midwest

Firerock 30 Inch Arched Outdoor Masonry Fireplace

Outdoor Fireplace Kits 36 In Pre Engineered Arched Masonry Mediterranean Terrace Other By Mantelsdirect Com Houzz Ie

Firerock Kits Versa Lok Midwest

Outdoor Fireplace Kits Your 1 Dealer

Firerock 3 Inch Literock Riser Kit For 30 Masonry Fireplaces

Firerock Rumford Kits Bellstone

30 In Firerock Masonry Wood Burning Outdoor Fireplace Mantels Direct

36 In Firerock Arched Masonry Outdoor Wood Burning Fireplace Kits Designs Backyard

30 In Firerock Masonry Wood Burning Outdoor Fireplace Mantels Direct