Firerock Fireplace Installation: A Comprehensive Guide

Firerock fireplaces represent a sophisticated and efficient approach to creating stunning masonry fireplace systems. Unlike traditional brick-and-mortar construction, Firerock utilizes pre-engineered, lightweight concrete forms to streamline the building process while offering enhanced performance and design flexibility. This article provides a comprehensive guide to Firerock fireplace installation, covering key aspects from planning and preparation to the final finishing touches.

The Firerock system is designed to minimize common issues associated with traditional masonry fireplaces, such as cracking, inefficient heating, and lengthy construction times. The modular nature of the components allows for a quicker and more precise build, resulting in a fireplace that is both aesthetically pleasing and functionally superior.

Understanding the Firerock System Components

Before embarking on a Firerock installation, it is essential to familiarize oneself with the core components of the system. These components are meticulously designed to work together, ensuring a robust and well-functioning fireplace:

Firebox: The firebox is the heart of the fireplace, providing the space for combustion. Firerock offers various firebox sizes and configurations to accommodate different design preferences and heating requirements. These are constructed from high-temperature refractory concrete, specifically formulated to withstand intense heat.

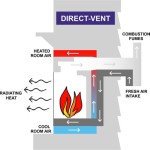

Throat and Smoke Chamber: The throat and smoke chamber are crucial for efficient smoke evacuation. Firerock's pre-engineered throat features a precisely angled design to optimize airflow and minimize smoke spillage into the room. The smoke chamber connects the throat to the chimney flue, providing a smooth transition for the smoke to escape.

Chimney Components: The chimney is responsible for venting combustion gases safely away from the living space. Firerock systems can be used with both masonry and UL-listed factory-built chimney systems. When using a masonry chimney, Firerock offers chimney components to ensure a secure and properly sized connection.

Facing Materials: The exterior of the Firerock fireplace can be finished with a wide range of materials, including brick, stone, stucco, and tile. This allows for seamless integration with the architectural style of the home.

Optional Components: Firerock offers a variety of optional components, such as arched lintels, corner units, and Rumford fireboxes, to further customize the fireplace design.

Planning and Preparation: The Foundation of a Successful Installation

Proper planning and preparation are paramount to a successful Firerock fireplace installation. This stage involves careful consideration of design requirements, structural considerations, and local building codes. Consult with a qualified architect or structural engineer to ensure that the fireplace design meets all applicable standards.

Design Considerations: Determine the desired size, style, and location of the fireplace. Consider the room's dimensions, existing architectural features, and the overall aesthetic you wish to achieve. Explore the various Firerock firebox options to select the size and configuration that best suits your needs. Also consider the integration of optional features such as wood storage or raised hearths.

Structural Requirements: Evaluate the structural capacity of the floor to support the weight of the fireplace. Firerock fireplaces, while lighter than traditional masonry structures, still require a solid foundation. In some cases, reinforcement may be necessary to ensure adequate support. Consult with a structural engineer to assess the floor's load-bearing capacity and determine if any modifications are required.

Building Codes and Permits: Research local building codes and obtain all necessary permits before starting the installation. Fireplace installations are typically subject to specific regulations regarding fire safety, chimney height, and clearances to combustible materials. Compliance with these codes is essential to ensure the safety and legality of the installation. The International Residential Code (IRC) and National Fire Protection Association (NFPA) standards provide general guidelines, but local codes take precedence.

Material Procurement: Once the design is finalized and permits are secured, order the necessary Firerock components and other materials. Ensure that you have a complete list of all required items, including mortar, reinforcing steel, facing materials, and chimney components. It's recommended to order slightly more material than estimated to account for waste and potential errors.

Site Preparation: Prepare the installation site by clearing the area of any obstructions and ensuring a level working surface. Protect surrounding surfaces from damage during the installation process. Having adequate space for maneuvering materials and tools is critical for efficient workflow.

Installation Process: Step-by-Step Guide

The Firerock installation process follows a specific sequence to ensure structural integrity and proper functionality. It is crucial to adhere to manufacturer's instructions and recommendations throughout the installation. While a skilled homeowner might undertake this project, professional installation is strongly recommended for optimal results.

Foundation Construction: Begin by constructing a solid foundation for the fireplace. This may involve pouring a concrete slab or building a reinforced masonry foundation. Ensure that the foundation is level and adequately sized to support the weight of the fireplace. Allow the foundation to cure completely before proceeding to the next step.

Firebox Assembly: Assemble the firebox according to the manufacturer's instructions. Carefully align and mortar the firebox components, ensuring tight joints and proper seating. Use a high-temperature refractory mortar specifically designed for fireplace construction. Reinforce the firebox with steel rebar as specified in the plans.

Throat and Smoke Chamber Installation: Install the throat and smoke chamber components on top of the firebox. Ensure that the throat is properly aligned and securely mortared in place. Pay close attention to the angle of the throat, as this is crucial for efficient smoke evacuation. The smoke chamber should be carefully aligned with the throat and chimney flue.

Chimney Construction: Construct the chimney according to local building codes and manufacturer's instructions. If using a masonry chimney, carefully lay the bricks or blocks, ensuring proper mortar joints and flue liner installation. If using a factory-built chimney, follow the manufacturer's instructions for assembly and installation. Ensure that the chimney extends a minimum of three feet above the roof and two feet above any structure within ten feet.

Facing Installation: Once the structural components are in place, install the desired facing materials around the fireplace. This may involve applying mortar, installing stone or brick veneer, or applying stucco. Ensure that the facing materials are securely attached to the fireplace structure. Pay attention to detail and strive for a clean and professional finish.

Finishing Touches: Complete the installation by adding the final finishing touches, such as a mantel, hearth, and trim. Ensure that all combustible materials are properly spaced away from the firebox opening. Inspect the entire installation for any defects or deficiencies and address them promptly.

Key Considerations During Installation

Several key considerations must be addressed during the Firerock installation process to ensure a safe and efficient fireplace:

Mortar Selection and Application: Using the correct type of mortar is crucial for the structural integrity and longevity of the fireplace. Refractory mortar is specifically designed to withstand the high temperatures encountered in a fireplace. Follow the manufacturer's instructions for mixing and applying the mortar. Ensure that all joints are completely filled and that excess mortar is cleaned away. Avoid using conventional mortar, as it is not designed for high-temperature applications and may crack and fail.

Clearances to Combustible Materials: Maintaining proper clearances to combustible materials is essential for fire safety. Consult local building codes and manufacturer's instructions for specific clearance requirements. Typically, combustibles should be kept at least six inches away from the firebox opening on the sides and top and at least twelve inches away from the firebox opening to the front. Use non-combustible materials, such as steel or cement board, to provide a barrier between the fireplace and any combustible materials.

Chimney Flue Sizing: Proper chimney flue sizing is critical for efficient smoke evacuation and to prevent backdrafting. The flue size should be appropriately matched to the firebox size. An undersized flue can restrict airflow and cause smoke to spill into the room, while an oversized flue can cool the smoke too quickly and cause condensation and creosote buildup. Consult a qualified professional to determine the correct flue size for your Firerock fireplace.

Waterproofing and Weather Protection: Protecting the fireplace from water damage is essential for its longevity. Apply a waterproof sealant to the exterior of the chimney and fireplace to prevent water penetration. Install a chimney cap to prevent rain and snow from entering the flue. Regularly inspect the chimney and fireplace for signs of water damage and address any leaks promptly.

Professional Inspection: Once the installation is complete, have a qualified professional inspect the fireplace to ensure that it meets all applicable codes and safety standards. A professional inspection can identify any potential problems and ensure that the fireplace is safe to use. Obtain written certification of the inspection for your records.

By following these guidelines and adhering to manufacturer's instructions, a safe and efficient Firerock fireplace installation can be achieved. Careful planning, proper execution, and diligent attention to detail are essential for creating a fireplace that will provide years of warmth and enjoyment.

Firerock Conventional Fireplace 42 Woodland Direct

How To Install A Firerock Outdoor Fireplace

Firerock Fireplaces South Alabama Brick Company

Firerock Fireplace Installation On Vimeo

Firerock Fireplaces South Alabama Brick Company

42 In Firerock Arched Masonry Outdoor Wood Burning Fireplace Kits

Firerock Outdoor Kits Bellstone

Morrell Masonry Supply Building Supplies Firerock Conventional 42 Inch Fireplace

Morrell Masonry Supply Building Supplies Firerock Conventional 48 Inch Fireplace

B Vent Indoor Fireplace Fireplaces By Firerock Legends Stone

Related Posts