Fireplace Spark Arrestor: Function, Selection, and Maintenance

A fireplace spark arrestor, also known as a chimney spark arrestor, is a crucial safety device for any home with a wood-burning fireplace or stove. Its primary function is to prevent sparks and embers from escaping the chimney and potentially igniting nearby combustible materials, such as roofs, trees, or dry vegetation. The installation and maintenance of a properly functioning spark arrestor are essential for minimizing the risk of chimney-related fires and adhering to local building codes.

Spark arrestors work by providing a mesh or screen barrier that allows smoke and exhaust gases to escape while trapping larger particles of burning material. These particles, if allowed to drift freely, can remain hot enough to start a fire upon landing on flammable surfaces. The effectiveness of a spark arrestor depends on several factors, including the mesh size, the overall design, and the material used in its construction. This article will detail the importance of spark arrestors, factors to consider when choosing one, and the recommended maintenance practices to ensure optimal performance and safety.

The Importance of Spark Arrestors in Fire Prevention

The primary reason for installing a spark arrestor is to prevent fires. Chimney fires are a common cause of residential fires, often originating from creosote buildup within the chimney flue. Creosote is a flammable byproduct of burning wood, and if it accumulates in sufficient quantities, it can ignite, creating intense heat and sending sparks and embers out of the chimney. A spark arrestor acts as a final line of defense, preventing these embers from spreading beyond the chimney's confines.

Beyond preventing fires originating directly from the chimney, spark arrestors also protect the surrounding property from external ignition. Even small embers carried by wind can travel considerable distances and ignite dry leaves, pine needles, or other combustible materials near the house. In regions prone to wildfires, a spark arrestor is particularly critical for reducing the risk of contributing to a larger, more devastating fire.

Furthermore, many jurisdictions have building codes and regulations that require the installation of spark arrestors on wood-burning appliances. Compliance with these codes is not only a legal obligation but also a responsible measure to ensure the safety of the community. Failure to comply can result in fines or even the inability to use the fireplace until a proper spark arrestor is installed.

Factors to Consider When Choosing a Spark Arrestor

Selecting the right spark arrestor involves considering several key factors to ensure it effectively performs its intended function and fits the specific chimney configuration. These factors include the size and shape of the chimney, the material of the spark arrestor, the mesh size, and any local regulations or requirements.

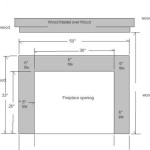

Chimney Size and Shape: Spark arrestors come in various sizes and shapes to accommodate different chimney designs. Chimneys can be round, square, or rectangular, and the spark arrestor must fit snugly over the flue opening to prevent sparks from escaping around the edges. Measuring the chimney's dimensions accurately is essential before purchasing a spark arrestor. For round chimneys, the diameter should be measured; for square or rectangular chimneys, the length and width should be noted. Adjustable spark arrestors are available, which can accommodate a range of chimney sizes, providing a flexible solution for installations where precise measurements are difficult to obtain. It's crucial to select an arrestor that provides complete coverage of the chimney opening without being overly restrictive, which could impede airflow.

Material: The material used in the construction of a spark arrestor significantly impacts its durability and resistance to corrosion. Common materials include stainless steel, galvanized steel, and copper. Stainless steel is generally considered the best option due to its superior corrosion resistance and long lifespan. Galvanized steel offers a more affordable alternative but is more susceptible to rust over time, particularly in areas with high humidity or exposure to saltwater. Copper spark arrestors are aesthetically pleasing and offer good corrosion resistance, but they are also the most expensive option. The choice of material should consider the local climate, the frequency of fireplace use, and the desired lifespan of the spark arrestor.

Mesh Size: The mesh size of the spark arrestor is the size of the openings in the screen. It is a critical factor in determining the arrestor's effectiveness in trapping sparks and embers. Most building codes specify the minimum mesh size required for spark arrestors. A common standard is a wire mesh with openings no larger than 1/2 inch. Smaller mesh sizes offer better protection against escaping embers but can also restrict airflow, potentially causing the fireplace to draft poorly. It's essential to strike a balance between ember containment and adequate ventilation to ensure the fireplace operates safely and efficiently. Overly restrictive mesh can lead to smoke backdrafting into the house, increasing the risk of carbon monoxide poisoning.

Local Regulations: Before purchasing and installing a spark arrestor, it is essential to check local building codes and regulations. Many jurisdictions have specific requirements for spark arrestors, including the type of material, mesh size, and installation procedures. Failure to comply with these regulations can result in fines or the need to replace the spark arrestor to meet the required standards. Contacting the local building department or fire marshal can provide valuable information on the specific requirements in a given area. Some areas may have specific requirements based on the proximity of the property to forested areas or other fire-prone environments.

Maintaining a Spark Arrestor for Optimal Performance

Regular maintenance of a spark arrestor is crucial to ensure its continued effectiveness in preventing fires. Over time, spark arrestors can become clogged with creosote, leaves, twigs, and other debris, which can restrict airflow and reduce their ability to trap sparks. Neglecting maintenance can lead to several problems, including reduced draft, increased creosote buildup in the chimney, and a higher risk of chimney fires. Maintenance typically involves inspecting the spark arrestor for damage or blockages and cleaning it as needed.

Inspection: Spark arrestors should be inspected at least once a year, preferably before the start of the heating season. The inspection should involve a visual examination of the arrestor to check for signs of damage, such as rust, corrosion, or broken mesh. Any significant damage should be addressed promptly, either by repairing the arrestor or replacing it. The inspection should also include checking for any obstructions, such as leaves, twigs, or bird nests, that may be blocking the airflow. A thorough inspection can help identify potential problems early, allowing for timely repairs and preventing more serious issues from developing.

Cleaning: The frequency of cleaning a spark arrestor depends on several factors, including the frequency of fireplace use, the type of wood burned, and the local environment. In general, spark arrestors should be cleaned at least once a year, or more frequently if they become heavily clogged. Cleaning can be done using a wire brush to remove creosote and other debris from the mesh. For more stubborn buildup, a chimney sweep may be required to perform a professional cleaning. When cleaning, it is essential to wear appropriate safety gear, such as gloves and eye protection, to avoid contact with creosote and other potentially hazardous materials. It's best practice to clean the chimney as part of the spark arrestor cleaning process to prevent recontamination of the arrestor.

Professional Chimney Sweeping: While homeowners can perform basic inspections and cleaning, it is recommended to have the chimney professionally swept at least once a year. Professional chimney sweeps have the tools and expertise to thoroughly clean the entire chimney system, including the flue, smoke chamber, and spark arrestor. They can also identify potential problems that might be missed during a homeowner inspection, such as cracks in the flue liner or excessive creosote buildup. A professional chimney sweep can also provide valuable advice on fireplace maintenance, wood selection, and safe burning practices. Investing in regular chimney sweeping is a proactive measure to ensure the safe and efficient operation of the fireplace.

By understanding the function of a spark arrestor, carefully selecting the appropriate type for the chimney, and implementing a regular maintenance schedule, homeowners can significantly reduce the risk of chimney fires and ensure the safe operation of their wood-burning appliances. Consistent upkeep and adherence to local regulations are key to maintaining a safe and efficient heating system.

Interior Exterior Spark Arrestors The Importance

Gibraltar Building S 15 In X 23 Galvanized Steel Adjustable Flue Guard Chimney Cap Spark Arrestor Black Cg4blk The Home Depot

13 X 17 Chimney Cap Spark Arrestor Outdoor Fireplace Top Flue Cover Stainless

Gibraltar Building S 15 In X 23 Galvanized Steel Adjustable Flue Guard Chimney Cap Spark Arrestor Black Cg4blk The Home Depot

What Is A Spark Arrestor On Chimney And It Necessary

Exterior Interior Spark Arrestors Prevent House Fires

Interior Exterior Spark Arrestors The Importance

Spark Arrestors Chimney Caps American Masonry

Chimney Caps And Spark Arrestors Brushers

Chimney Spark Arrestor Why Use Woven Wire Mesh

Related Posts