Understanding Fireplace Log Starter Gas Systems

Fireplace log starter gas systems offer a convenient and efficient method for initiating wood-burning fires in fireplaces. These systems eliminate the need for kindling and paper, significantly simplifying the fire-starting process. They operate by delivering a controlled flow of natural gas or propane through a burner positioned beneath the wood logs. The ignited gas provides the heat necessary to ignite the logs, establishing a sustainable fire. Understanding the components, operation, installation, and safety considerations surrounding these systems is crucial for informed decision-making and responsible usage.

These systems are popular due to their ease of use and time-saving benefits. Traditional fire-starting methods often involve gathering and arranging kindling, layering paper, and meticulously monitoring the flame's progress. Log starter gas systems circumvent these steps, offering a quicker and more reliable solution. This convenience is particularly appealing during colder months when individuals seek immediate warmth and comfort from a fireplace. Furthermore, these systems contribute to cleaner burning by reducing the reliance on paper and kindling, which can produce significant amounts of smoke and ash.

The components of a fireplace log starter gas system typically include a gas supply line, a shut-off valve, a burner assembly, and a control mechanism. The gas supply line connects the system to either a natural gas or propane source. The shut-off valve provides a means to isolate the gas supply for maintenance or emergencies. The burner assembly, usually constructed of durable metal, distributes the gas evenly beneath the wood logs. The control mechanism, which can range from a simple manual valve to a more sophisticated electronic ignition system, regulates the flow of gas to the burner.

The operational principle of a log starter gas system is relatively straightforward. When the control mechanism is activated, gas flows through the supply line and into the burner assembly. A spark or pilot light then ignites the gas, producing a flame that rises to contact the wood logs. As the logs begin to burn, they generate sufficient heat to sustain the fire independently. At this point, the gas supply can be turned off, allowing the fire to burn naturally. The duration of gas usage depends on the size and type of wood logs, as well as the desired intensity of the fire.

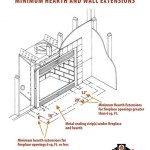

Installation of a fireplace log starter gas system requires adherence to local building codes and regulations. It is generally recommended that a qualified professional perform the installation to ensure proper connections, gas line integrity, and safe operation. Improper installation can lead to gas leaks, fire hazards, and potential health risks. The installation process typically involves connecting the gas supply line to the existing gas infrastructure, mounting the burner assembly within the fireplace, and testing the system for leaks and functionality.

Regular maintenance is essential for ensuring the safe and efficient operation of a log starter gas system. This includes inspecting the gas supply line for leaks or damage, cleaning the burner assembly to remove debris, and verifying the functionality of the shut-off valve and control mechanism. Periodic professional inspections are also recommended to identify potential issues before they escalate into more serious problems. Neglecting maintenance can lead to decreased performance, increased risk of gas leaks, and potential safety hazards.

Key Considerations for Choosing a Log Starter Gas System

Selecting the appropriate log starter gas system involves several key considerations. First, the fuel type must be determined, as natural gas and propane systems operate differently and require different connections. Second, the size and configuration of the fireplace must be taken into account to ensure proper burner placement and adequate heat distribution. Third, the control mechanism should be chosen based on user preference and desired level of automation. Manual systems offer simplicity and affordability, while electronic ignition systems provide convenience and enhanced safety features. Finally, the overall quality and durability of the system should be assessed to ensure long-term performance and reliability.

The choice between natural gas and propane as a fuel source hinges on several factors. Natural gas is typically more cost-effective, especially in areas where it is readily available through municipal pipelines. However, propane offers greater portability and can be used in locations where natural gas connections are not accessible. Propane tanks require separate storage and refilling, which can add to the overall cost and complexity. The decision ultimately depends on the availability of each fuel source, the cost of installation and operation, and individual preferences.

The size and configuration of the fireplace play a crucial role in determining the appropriate burner size and placement. A burner that is too small may not provide sufficient heat to ignite the logs effectively, while a burner that is too large may produce excessive heat and potentially damage the fireplace. The burner should be positioned to evenly distribute heat beneath the logs, ensuring consistent ignition across the firebox. Irregularly shaped fireplaces may require custom burner configurations to optimize performance.

The control mechanism governs the operation and safety of the log starter gas system. Manual systems typically consist of a simple valve that controls the flow of gas. These systems are relatively inexpensive and easy to operate, but they require manual ignition of the gas. Electronic ignition systems offer a more convenient and safer alternative. These systems use an electronic spark to ignite the gas, eliminating the need for a manual lighter and reducing the risk of accidental burns. Some electronic ignition systems also include safety features such as automatic shut-off in the event of a gas leak or flame failure.

Safety Measures for Operating Log Starter Gas Systems

Safety is paramount when operating a log starter gas system. Gas leaks pose a significant hazard, and it is crucial to detect and address them promptly. Carbon monoxide poisoning is another potential risk, particularly if the fireplace is not properly ventilated. Following safety guidelines and implementing safety measures can significantly reduce the risk of accidents and ensure a safe and enjoyable fireplace experience.

Gas leaks can be detected by a distinct odor of gas, a hissing sound near the gas line or connections, or the appearance of bubbles when soapy water is applied to the gas line. If a gas leak is suspected, the gas supply should be immediately shut off at the shut-off valve. All flames and ignition sources should be extinguished, and the area should be ventilated. A qualified professional should be contacted to inspect and repair the system before it is used again. Never attempt to repair a gas leak without proper training and equipment.

Carbon monoxide is a colorless, odorless, and poisonous gas produced by the incomplete combustion of fuels, including natural gas and propane. Proper ventilation is essential to prevent carbon monoxide from building up in the home. A functioning carbon monoxide detector should be installed near the fireplace to provide an early warning of dangerous levels of the gas. Symptoms of carbon monoxide poisoning include headache, dizziness, nausea, and confusion. If carbon monoxide poisoning is suspected, the area should be immediately ventilated, and medical attention should be sought.

Regular inspections and maintenance are critical for preventing gas leaks and carbon monoxide poisoning. The gas supply line, burner assembly, and control mechanism should be inspected for any signs of damage or deterioration. The fireplace and chimney should be cleaned regularly to remove creosote buildup, which can obstruct airflow and increase the risk of chimney fires and carbon monoxide poisoning. A qualified professional should be consulted for any repairs or maintenance that require specialized knowledge or equipment.

Troubleshooting Common Problems with Log Starter Gas Systems

Log starter gas systems, like any mechanical system, can experience occasional problems. Common issues include difficulty igniting the gas, uneven flame distribution, and gas leaks. Troubleshooting these problems involves systematically identifying the cause and implementing appropriate solutions. Consulting the manufacturer's instructions and seeking professional assistance when necessary can help resolve these issues efficiently and safely.

Difficulty igniting the gas can be caused by several factors, including a faulty igniter, a clogged burner, or a low gas supply pressure. If the igniter is not producing a spark, it may need to be replaced. A clogged burner can be cleaned with a wire brush or compressed air. Low gas supply pressure can be caused by a problem with the gas supply line or regulator. A qualified professional should be contacted to diagnose and repair any issues with the gas supply system.

Uneven flame distribution can be caused by a clogged burner, improper burner placement, or variations in gas pressure. The burner should be cleaned and repositioned to ensure even heat distribution beneath the logs. Gas pressure should be checked to ensure that it is within the recommended range. A qualified professional can adjust the gas pressure if necessary.

Gas leaks, as previously mentioned, require immediate attention. If a gas leak is suspected, the gas supply should be immediately shut off, all flames and ignition sources should be extinguished, and the area should be ventilated. A qualified professional should be contacted to inspect and repair the system before it is used again. Attempting to repair a gas leak without proper training and equipment can be dangerous and should be avoided.

By understanding the components, operation, installation, safety considerations, and troubleshooting techniques associated with fireplace log starter gas systems, individuals can make informed decisions and ensure the safe and efficient use of these convenient fire-starting solutions.

How To Install A Log Lighter Fireplace Gas Starter Pipe

New Gas Logs For Fall Seattle Wa Pristine Sweeps

.png?strip=all)

How To Install A Log Lighter Fireplace Gas Starter Pipe

Gas Log Lighter Fireplace Accessories At Com

Pro Flex Hearth Master Natural Gas Log Lighter Bar In The Fireplace Accessories Department At Com

Is A Gas Log Lighter Dangerous

Want To Convert Gas Wood Fireplace Full Service Chimney

Blue Flame 16 5 In Straight Natural Gas Log Lighter With Exclusive Air Mixing Chamber 26 000 Btu Lls 1626 Ng The Home Depot

Stanbroil Universal Gas Log Lighter Starter With Mixer For Propane Wood Burning Fireplaces Outdoor

Cast Iron Log Lighter 12 Inch For Natural Gas

Related Posts