Fireplace Insert: Wood Burning with Blower

A fireplace insert is a self-contained heating appliance designed to be installed inside an existing masonry or factory-built fireplace. Wood-burning models offer a blend of traditional aesthetics and enhanced heating efficiency. Integrating a blower system further optimizes heat distribution, making these inserts a practical and cost-effective alternative or supplement to central heating systems. Understanding the features, benefits, and installation considerations of a wood-burning fireplace insert with a blower is crucial for making an informed purchasing decision.

Fireplace inserts aim to address the inherent inefficiencies of traditional open fireplaces. A significant portion of the heat generated by an open fireplace escapes up the chimney, providing minimal warmth to the room. Fireplace inserts, being closed combustion systems, significantly reduce heat loss through the chimney by controlling airflow and maximizing combustion efficiency. They are constructed from materials like cast iron or steel, designed to withstand high temperatures and radiate heat effectively into the surrounding space.

The addition of a blower system differentiates some wood-burning inserts from others. A blower, typically an electric fan, forces air across the heated firebox of the insert and then circulates the warmed air into the room. This forced-air convection dramatically increases the rate and range of heat distribution compared to relying solely on radiant heat. This results in a more evenly heated room and allows the insert to effectively warm larger areas.

Selecting the right fireplace insert involves careful consideration of several factors, including the size of the area to be heated, the existing fireplace opening dimensions, and any local building codes or regulations. Proper installation by a qualified professional is essential to ensure safe and efficient operation.

Enhanced Heating Efficiency

The primary advantage of a wood-burning fireplace insert with a blower lies in its enhanced heating efficiency compared to an open fireplace. Open fireplaces, by their nature, are highly inefficient. They draw air from the room for combustion, which is then expelled up the chimney, creating a negative pressure that draws cold air into the room from other areas. This process can actually lead to a net loss of heat within the home, despite the visual warmth of the fire.

Fireplace inserts, on the other hand, are designed to minimize heat loss. The closed combustion chamber limits the amount of air required for combustion, reducing the draft up the chimney. More importantly, the insert’s design focuses on extracting as much heat as possible from the burning wood. Features like secondary combustion systems, which burn off gases that would otherwise escape as smoke, contribute to increased efficiency.

The blower system plays a crucial role in maximizing heat output. By forcing air across the firebox, the blower increases the surface area from which heat is transferred to the surrounding air. This forced convection heating is far more effective at distributing heat than relying solely on radiant heat, which diminishes rapidly with distance from the heat source. The result is a more consistent and comfortable temperature throughout the room and potentially in adjacent areas as well.

The efficiency of a wood-burning insert is often measured by its heat output, typically expressed in British Thermal Units (BTUs). Selecting an insert with an appropriate BTU rating for the size of the space to be heated is essential for optimal performance. A unit that is too small will struggle to adequately warm the area, while a unit that is too large may overheat the room and lead to uncomfortable temperature fluctuations.

Furthermore, the use of seasoned wood is critical for achieving optimal efficiency. Green or unseasoned wood contains a high moisture content, which reduces the heat output of the fire and increases the production of smoke and creosote. Seasoned wood, which has been properly dried for at least six months, burns hotter and cleaner, maximizing the efficiency of the insert and minimizing the risk of chimney fires.

Blower System Functionality and Benefits

The blower system integrated into a wood-burning fireplace insert is responsible for circulating heated air throughout the room. The blower typically consists of an electric fan, housed within the insert, that draws air from the room, forces it across the heated surfaces of the firebox, and then expels the warmed air back into the room through vents or louvers.

The primary benefit of the blower is to increase the rate and range of heat distribution. Without a blower, the insert primarily relies on radiant heat, which is most effective in close proximity to the unit. Radiant heat diminishes rapidly with distance, leading to uneven heating within the room. The blower, by contrast, actively circulates the heated air, ensuring that warmth is distributed more evenly throughout the space.

Most blower systems offer adjustable speed settings, allowing the user to control the amount of air being circulated and the intensity of the heat output. This feature is particularly useful for maintaining a comfortable temperature in varying weather conditions, or adjusting heating to different room sizes.

The airflow created by the blower also helps to prevent overheating of the insert. By constantly drawing air across the firebox, the blower helps to dissipate heat and prevent the insert from reaching excessively high temperatures. This is especially important for inserts with large fireboxes or those used for extended periods of time.

The noise level of the blower is a consideration for some users. While most modern blowers are designed to operate quietly, some models may produce a noticeable hum or whirring sound. It is advisable to research the noise level of different blower systems before making a purchase. Some users may find the sound to be unobtrusive, while others may find it distracting.

Blower systems typically require electricity to operate. This means that the insert will not function as a heating source during a power outage, unless it is connected to a backup power source such as a generator. It is important to consider this limitation when evaluating the suitability of a wood-burning insert with a blower for emergency heating situations.

Installation and Safety Considerations

Proper installation of a wood-burning fireplace insert is crucial for ensuring safe and efficient operation. It is highly recommended that installation be performed by a qualified and certified professional. Improper installation can lead to a variety of problems, including reduced heating efficiency, increased risk of chimney fires, and potential carbon monoxide poisoning.

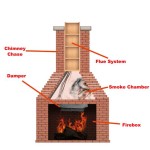

Before installing an insert, it is essential to inspect the existing fireplace and chimney to ensure that they are in good condition and meet all applicable building codes. The chimney must be properly sized and lined to accommodate the insert. Any cracks or damage to the chimney must be repaired before installation.

The insert must be properly connected to the chimney flue using a connector pipe of the correct diameter and material. The connector pipe must be securely attached to both the insert and the chimney flue to prevent leaks of smoke and carbon monoxide. The area around the insert must be non-combustible material and installed as per manufacturer's requirement.

Clearance requirements must be strictly adhered to. These requirements specify the minimum distance between the insert and any combustible materials, such as walls, furniture, and curtains. Failure to maintain adequate clearances can create a fire hazard.

A carbon monoxide detector must be installed in the room where the insert is located. Carbon monoxide is a colorless, odorless gas that can be produced by incomplete combustion. It is highly toxic and can be fatal. A carbon monoxide detector will provide an early warning of dangerous levels of carbon monoxide in the air.

Regular maintenance is essential for ensuring the safe and efficient operation of a wood-burning fireplace insert. The chimney should be inspected and cleaned annually by a qualified chimney sweep. Cleaning removes creosote buildup, which is a flammable substance that can accumulate in the chimney and cause chimney fires. The insert itself should also be inspected regularly for any signs of damage or wear. The door gasket, which seals the firebox, should be replaced if it becomes damaged or worn. The blower should be cleaned periodically to remove dust and debris, which can reduce its efficiency and increase the risk of overheating.

Ventis Hei240 Wood Burning Insert

Wood Burning Fireplace Inserts 1 Stove Insert Dealer

Why A Wood Burning Fireplace Insert Bethesda Md Service

Inserts Wood Osburn 2200 Insert With Blower Ob02201

Osburn 3500 Wood Burning Fireplace Insert 31 Ob03510 Hvacdirect Com

S25i Napoleon

Ventis Wood Burning Fireplace Insert With Blower Hei170 Hvacdirect Com

Why A Wood Burning Fireplace Insert Bethesda Md Service

Premium Wood Fireplace Inserts Made In Usa Lopi Stoves

35 Ruby Traditional Intellifire Touch Direct Vent Fireplace Insert Blower And Remote Electronic Ignition Majestic