Fireplace Insert Replacement Parts: A Comprehensive Guide

Fireplace inserts, designed to enhance the efficiency and aesthetic appeal of existing fireplaces, are complex appliances composed of numerous individual components. Over time, these parts can wear down, break, or become obsolete, necessitating replacement to ensure the continued safe and effective operation of the fireplace insert. Understanding the common replacement parts, their function, and the factors to consider when selecting replacements is crucial for homeowners and technicians alike.

This article provides a detailed overview of fireplace insert replacement parts, covering various types of inserts (gas, wood, and electric), common components requiring replacement, factors influencing the selection of suitable parts, and general maintenance practices to prolong the lifespan of these parts.

Gas Fireplace Insert Replacement Parts

Gas fireplace inserts offer convenience and ease of use, but their reliance on gas combustion introduces specific components prone to wear and tear. Regular inspection and timely replacement of these parts are vital for maintaining safe and efficient operation.

One of the most critical components is the gas valve. The gas valve regulates the flow of gas to the burner, controlling the flame height and heat output. Over time, the valve can become clogged with debris or experience mechanical failure, leading to reduced flame, inconsistent burning, or complete shut-off. Replacing a gas valve requires meticulous attention to detail and adherence to safety protocols, often necessitating the expertise of a qualified technician. Ensuring the replacement valve is compatible with the specific model and gas type (natural gas or propane) is paramount.

Thermocouples and thermopiles are safety devices that detect the presence of a pilot flame. If the pilot light is extinguished, these devices signal the gas valve to shut off the gas supply, preventing gas leaks. These components are susceptible to corrosion and burnout, leading to pilot light malfunctions. Replacing a thermocouple or thermopile is relatively straightforward but requires careful handling to avoid damage. Selecting the correct length and type is essential for proper functionality.

Burners are responsible for distributing the gas and creating a stable flame. They can corrode or become clogged with soot and debris, resulting in uneven flames, reduced heat output, or noisy operation. Cleaning the burner ports can sometimes resolve minor issues, but in severe cases, replacement is necessary. When replacing a burner, it's crucial to match the burner design and dimensions to the original part to ensure proper flame patterns and combustion efficiency.

Pilot assemblies ignite the gas and maintain a pilot flame, which then ignites the main burner. Pilot assemblies can become corroded, clogged, or experience damage to the igniter. Replacement requires careful alignment and adjustment to ensure reliable ignition. Matching the pilot assembly to the specific model of the insert is crucial for proper functionality.

Finally, ceramic logs and embers are aesthetic components that enhance the visual appeal of the fireplace. While not essential for operation, they can crack, discolor, or deteriorate over time. Replacing these components is primarily for aesthetic purposes and allows homeowners to customize the appearance of their fireplace. When selecting replacement logs, consider the size, shape, and material to match the existing design or create a new aesthetic.

Wood Fireplace Insert Replacement Parts

Wood fireplace inserts provide a traditional heating experience, but the high temperatures and corrosive byproducts of wood combustion can lead to significant wear and tear on various components. Regular inspections and timely replacements are crucial for safety and optimal performance.

Baffles, also known as heat shields or air directors, are essential for directing airflow within the firebox, improving combustion efficiency, and protecting the firebox ceiling from excessive heat. These components are exposed to extreme temperatures and can warp, crack, or burn through over time. Replacing a baffle requires selecting a replacement made from a similar material (typically steel or cast iron) and matching the dimensions to the original part to ensure proper fit and functionality.

Firebricks line the interior of the firebox, protecting the outer shell from the intense heat of the fire. These bricks are designed to withstand high temperatures, but they can crack, crumble, or deteriorate over time. Replacing firebricks is essential for maintaining the structural integrity of the firebox and preventing damage to the surrounding materials. Selecting firebricks of the correct size and thickness is crucial for a proper fit.

Door gaskets seal the door of the insert, preventing air leaks and ensuring proper combustion. These gaskets can become brittle, cracked, or compressed over time, leading to reduced efficiency and increased creosote buildup. Replacing a door gasket is a relatively simple task that can significantly improve the performance of the insert. Selecting a gasket of the correct diameter and material (typically fiberglass or ceramic fiber) is important for a tight seal.

Glass doors provide a view of the fire and help to contain sparks and embers. The glass can crack or break due to thermal shock or impact. Replacing the glass requires selecting a high-temperature-resistant glass specifically designed for fireplace inserts. Measuring the dimensions of the existing glass is crucial for a proper fit. Secure the glass to the door frame with the correct type of gasket or sealant.

Air controls regulate the amount of air entering the firebox, controlling the burn rate and heat output. These controls can become stiff, corroded, or damaged, making it difficult to adjust the fire. Replacing an air control requires selecting a replacement that is compatible with the specific model of the insert. Proper installation and adjustment are essential for optimal performance.

Electric Fireplace Insert Replacement Parts

Electric fireplace inserts offer a convenient and relatively maintenance-free heating solution. While they don't involve combustion, certain components can still require replacement over time.

Heating elements are responsible for generating heat in electric fireplace inserts. They can burn out or become less efficient over time, leading to reduced heat output. Replacing a heating element requires selecting a replacement with the correct voltage and wattage rating to match the original part. Disconnecting the power supply and following safety precautions are essential during the replacement process.

Flame effect motors and components create the visual illusion of flames. These components can fail due to wear and tear, resulting in a flickering or non-functioning flame effect. Replacing these components requires selecting a replacement that is compatible with the specific model of the insert. Careful disassembly and reassembly are often required.

Light bulbs or LED lights illuminate the flame effect. These bulbs can burn out or dim over time, reducing the brightness of the flame effect. Replacing these bulbs is a simple task that can significantly improve the visual appeal of the fireplace. Selecting bulbs with the correct voltage and wattage is essential.

Switches and controls regulate the power, heat output, and flame effect settings. These components can become damaged or malfunction, making it difficult to control the fireplace. Replacing these components requires selecting a replacement that is compatible with the specific model of the insert. Wiring connections should be carefully documented and reconnected correctly.

Thermostats regulate the temperature of the room. If the thermostat fails, the fireplace may not heat properly or may overheat. Replacing the thermostat requires selecting a replacement with the correct temperature range and sensitivity. Proper calibration is essential for accurate temperature control.

Factors Influencing Replacement Part Selection

Selecting the correct replacement parts is crucial for ensuring the safe and efficient operation of a fireplace insert. Several factors must be considered to ensure compatibility and optimal performance.

Model compatibility is paramount. Replacement parts must be specifically designed for the make and model of the fireplace insert. Using generic or incompatible parts can lead to poor performance, safety hazards, or damage to the appliance. Always refer to the manufacturer's specifications or consult with a qualified technician to ensure compatibility.

Material quality and durability are important considerations, especially for components exposed to high temperatures or corrosive environments. Selecting parts made from high-quality materials can prolong their lifespan and reduce the frequency of replacements. Consider the original material used in the part and opt for a similar or superior material for the replacement.

Safety certifications and standards ensure that replacement parts meet specific safety requirements and performance standards. Look for parts that are certified by recognized organizations, such as UL, CSA, or ETL. These certifications indicate that the parts have been tested and approved for safe use.

Warranty coverage provides protection against defects and premature failure. Selecting parts with a warranty can provide peace of mind and reduce the financial burden of future replacements. Read the warranty terms carefully to understand the coverage and any limitations.

Consulting with a qualified technician is recommended, especially for complex repairs or when unsure about selecting the correct replacement parts. A technician can diagnose the problem accurately, identify the appropriate replacement parts, and ensure proper installation.

General Maintenance Practices

Regular maintenance can significantly extend the lifespan of fireplace insert components and prevent premature failure. Implementing a proactive maintenance schedule is crucial for ensuring safe and efficient operation.

Regular cleaning is essential for removing soot, ash, and debris from the firebox, burner, and ventilation system. Cleaning can improve combustion efficiency, prevent corrosion, and reduce the risk of chimney fires. Follow the manufacturer's recommendations for cleaning frequency and methods.

Inspecting components regularly can identify potential issues before they escalate into major problems. Check for cracks, corrosion, wear, and damage to all visible components. Pay particular attention to critical safety devices, such as thermocouples, thermopiles, and gas valves.

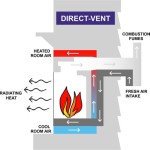

Proper ventilation is crucial for ensuring complete combustion and preventing the buildup of harmful gases. Ensure that the chimney or vent system is clean and unobstructed. Schedule regular chimney inspections and cleanings to remove creosote buildup.

Using the correct fuel is essential for optimal performance and longevity. Use only seasoned, dry wood in wood-burning inserts. For gas inserts, ensure that the gas supply is clean and properly regulated. Avoid using accelerants or other flammable materials in any type of fireplace insert.

Storing replacement parts on hand can minimize downtime and facilitate quick repairs. Stock common replacement parts, such as thermocouples, door gaskets, and light bulbs. Ensure that the replacement parts are stored in a clean, dry environment to prevent deterioration.

Monessen Ildv30 Direct Vent Gas Fireplace Insert Ildv Series Ereplacementparts Com

Ewf30 Wfe05h0 The Cozy Cabin Stove Fireplace Parts

Gas Fireplace Natural Bdm35 The Cozy Cabin Lennox Hearth Parts

Cgcftn Fireplace Parts For Desa Comfortglow Partsfor Com

Direct Vent Gas Fireplace Insert Dri3030ten The Cozy Cabin Lennox Hearth Parts

G400 Series G450 G490 Natural Vent Gas Fireplace 114 117 Vermontcastings Parts For Vermont Castings Majestic

Napoleon Parts

Regency Replacement Parts Friendly Fires

Small Winterwarm Insert 2080 2082 2084 The Cozy Cabin Stove Fireplace Parts

Astria Capella Traditional Electric Fireplace 36 Capella36 The Cozy Cabin Lennox Hearth Parts

Related Posts