Understanding Fireplace Double Wall Vent Pipe

Fireplace double wall vent pipe is a critical component in safely venting combustion byproducts from a fireplace or wood-burning stove to the outside atmosphere. Unlike single-wall vent pipes, double-wall systems provide an added layer of safety and efficiency, minimizing the risk of fire hazards and improving the overall performance of the heating appliance. This document provides a comprehensive overview of double-wall vent pipe, its construction, purpose, advantages, installation considerations, and maintenance practices.

The primary function of any vent pipe is to remove the toxic gases produced during combustion, including carbon monoxide, which is odorless and potentially lethal. Proper venting is essential for ensuring the health and safety of occupants, as well as preventing structural damage to the building. Double-wall vent pipe offers a superior solution compared to single-wall alternatives due to its enhanced insulation and reduced surface temperatures.

Key Point 1: Construction and Materials

Double-wall vent pipe consists of two concentric metal pipes, with an air space or insulation material between them. This design creates a thermal barrier that significantly reduces the amount of heat radiating from the outer pipe. This reduction in radiant heat is a key safety feature, minimizing the risk of igniting nearby combustibles such as wood framing, insulation, or other building materials. The materials used in the construction of double-wall vent pipe are typically stainless steel or galvanized steel, chosen for their durability, corrosion resistance, and ability to withstand high temperatures. Stainless steel offers superior corrosion resistance compared to galvanized steel, particularly in environments with high humidity or acidic combustion byproducts.

The inner pipe, also known as the flue liner, is directly exposed to the hot exhaust gases. It must be able to withstand extreme temperatures and resist corrosion from acidic compounds present in the smoke. The outer pipe provides structural support and acts as a protective shield, preventing contact with hot surfaces and reducing the risk of accidental burns. The space between the inner and outer pipes is either filled with air or an insulating material, further reducing heat transfer. Some manufacturers use fiberglass or ceramic fiber insulation to enhance the thermal performance of the vent pipe.

The thickness of the metal used in double-wall vent pipe is crucial for its structural integrity and longevity. Thicker gauge metal provides greater resistance to deformation and corrosion, ensuring a longer lifespan for the venting system. It's crucial to verify that the double-wall pipe is UL listed and meets the manufacturer's specifications for the fireplace or stove it serves.

Key Point 2: Advantages of Double Wall Vent Pipe

The adoption of double-wall vent pipe offers numerous advantages compared to single-wall systems. Perhaps the most significant benefit is the enhanced safety provided by the reduced surface temperatures. This minimizes the required clearances to combustible materials, allowing for more flexible installation options while maintaining a high level of fire safety. This is particularly important in older homes where space may be limited and clearances to combustible materials are constrained.

Another key advantage is improved draft performance. The insulation effect of the double-wall construction helps maintain a higher flue gas temperature, which promotes a stronger draft. A strong draft is essential for efficiently removing combustion byproducts from the fireplace or stove and preventing backdrafting, which can lead to smoke entering the living space. Furthermore, a good draft contributes to cleaner burning, reducing the amount of creosote buildup in the vent pipe.

Double-wall vent pipe also contributes to improved energy efficiency. By reducing heat loss through the vent pipe, more heat is retained within the living space. This can result in lower heating costs and a more comfortable indoor environment. While the energy savings may not be substantial, they are a welcome byproduct of using a safer and more efficient venting system.

Key Point 3: Installation and Maintenance Considerations

Proper installation is paramount for the safe and effective operation of double-wall vent pipe. Installation should always be performed by a qualified professional who is familiar with local building codes and manufacturer's instructions. Following the manufacturer's guidelines ensures that the vent pipe is installed correctly and that all necessary clearances to combustible materials are maintained. Cutting corners during installation can compromise the safety and performance of the venting system.

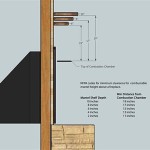

Adequate clearances to combustible materials are essential to prevent fire hazards. The manufacturer's specifications will outline the minimum required clearances for different parts of the vent pipe and any necessary shielding or heat protection measures. These clearances must be strictly adhered to during installation. Furthermore, the vent pipe must be properly supported to prevent sagging or movement, which could compromise its integrity and safety.

Regular inspection and maintenance are also crucial for maintaining the safety and efficiency of double-wall vent pipe. The vent pipe should be inspected annually for signs of damage, corrosion, or creosote buildup. Creosote is a highly flammable substance that can accumulate in the vent pipe and pose a significant fire hazard. Regular cleaning of the vent pipe is essential to remove creosote and prevent chimney fires. A professional chimney sweep should be hired to perform this task, as they have the necessary tools and expertise to safely and effectively clean the vent pipe. Promptly addressing any signs of damage or corrosion is essential for preventing further deterioration and ensuring the continued safe operation of the fireplace or stove.

Finally, ensure that all connections are secure and properly sealed to prevent leaks of combustion byproducts. Use the appropriate sealant recommended by the vent pipe manufacturer. Carbon monoxide detectors should be installed and maintained in the home to provide an early warning of any leaks or backdrafting issues.

Z Vent Special Gas Double Wall Flex

Duravent Pelletvent 4 In X 24 Double Wall Chimney Stove Pipe 4pvl The Home Depot

Duravent Dvl 6 In X 48 Double Wall Black Chimney Stove Pipe 6dvl The Home Depot

Chimney And Venting Pipe Guide Fireplaces Direct Learning Center

Ventis Double Wall Black Stove Pipe Chimney

Double Wall Black Stove Pipe Wood Rockford Chimney

Duravent Pelletvent 4 In 10 X 12 Adjustable Double Wall Chimney Stove Pipe 4pvl A12 The Home Depot

Duravent Pelletvent 4 In X 60 Double Wall Chimney Stove Pipe Black 4pvl 60b The Home Depot

Duravent Dvl 6 In X 60 Double Wall Close Clearance Stove Pipe Connector Kit Black 6dvl Kvp The Home Depot

Through The Wall Kit For Rock Vent Insulated Class A Chimney Pipe Rockford

Related Posts