Understanding Fireplace Cast Iron Grates

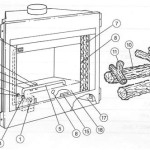

A fireplace cast iron grate is an essential component of any wood-burning fireplace. Its primary function is to elevate the firewood off the fireplace floor, allowing for improved airflow around the logs. This enhanced airflow leads to more efficient combustion, resulting in a hotter, brighter, and cleaner burn. Consequently, a well-chosen cast iron grate contributes to a more enjoyable and effective fireplace experience.

The material composition of a fireplace grate significantly influences its performance and longevity. Cast iron, a durable and heat-resistant metal, is the traditional and often preferred material. Its ability to withstand high temperatures without warping or cracking makes it a reliable choice for repeated use in a fireplace. However, understanding the different types of cast iron and the factors that affect their durability is crucial for selecting the right grate.

Beyond material, the design and construction of the grate are also important considerations. Variations in bar spacing, grate size, and reinforcement features can impact airflow and weight-bearing capacity. Therefore, selecting a grate that is appropriately sized for the fireplace and designed to handle the anticipated weight of the firewood is crucial for optimal performance and safety.

Airflow and Combustion Efficiency

The primary advantage of using a cast iron grate is the improved airflow it provides to the fire. By lifting the firewood above the fireplace floor, the grate creates space for air to circulate beneath the logs. This allows oxygen to reach all sides of the wood, promoting more complete combustion. When wood burns more efficiently, it produces more heat with less smoke and fewer unburnt particles, leading to a cleaner and more sustainable fire.

The design of the grate, particularly the spacing between the bars, plays a vital role in airflow optimization. Narrowly spaced bars may prevent smaller pieces of wood from falling through, but they can also restrict airflow and hinder combustion. Conversely, widely spaced bars allow for better airflow but may not provide adequate support for smaller pieces of wood, potentially leading to them falling through and making the fire less efficient. The ideal bar spacing for a fireplace grate is a balance between these two factors, based on the typical size of the firewood used.

Furthermore, the presence of ash build-up on the fireplace floor can impede airflow even with a grate. Regular cleaning of the ash from under the grate is therefore essential to maintaining optimal combustion efficiency. Removing the ash allows for unobstructed airflow, ensuring that the fire continues to burn brightly and efficiently.

Durability and Material Considerations

Cast iron is prized for its ability to withstand high temperatures without significant deformation or degradation. The heat resistance of cast iron is directly related to its composition and the manufacturing process. Higher quality cast iron grates are often made with alloys that further enhance their heat resistance and durability.

However, not all cast iron is created equal. The presence of impurities or imperfections in the casting process can weaken the grate and make it more susceptible to cracking or warping under thermal stress. Therefore, purchasing a grate from a reputable manufacturer with a proven track record of producing high-quality cast iron products is advisable.

Proper maintenance can also significantly extend the lifespan of a cast iron grate. Regular cleaning to remove ash and creosote build-up can prevent corrosion and improve its heat transfer efficiency. Avoiding sudden temperature shocks, such as dousing a hot grate with water, can also help prevent cracking or warping. Applying a thin coat of heat-resistant paint or oil can provide additional protection against rust and corrosion, especially during periods of non-use.

Sizing and Fireplace Compatibility

Selecting the appropriate size of cast iron grate for a fireplace is crucial for both safety and performance. A grate that is too small may not provide adequate support for the firewood, leading to inefficient burning and potential hazards. Conversely, a grate that is too large may restrict airflow and make it difficult to manage the fire.

To determine the correct size of grate, measure the width and depth of the fireplace firebox. The grate should be slightly smaller than these dimensions, leaving a margin of space around the edges. This allows for adequate airflow around the fire and prevents the grate from rubbing against the sides of the fireplace, which can cause damage over time.

In addition to size, the grate's weight-bearing capacity should also be considered. Choose a grate that is designed to handle the anticipated weight of the firewood. Overloading a grate can lead to its premature failure, potentially causing a fire hazard. Always consult the manufacturer's specifications for the recommended weight limit before using the grate.

Liberty Foundry 22 In Cast Iron Heavy Duty Fireplace Grate With 2 Clearance G22 Bx The Home Depot

17 Wide Small Cast Iron Fireplace Wood Fire Grate

Aqbau Cast Iron Grate Furnace Fireplace Ash Rust Grating

Open Hearth Collection Cast Iron Fireplace Grate 15418 Blain S Farm Fleet

Eclectic Red Barn Antique Fireplace Grate Decorated For

Oven Grate 15 5 X 25 Cm Fireplace Made Of Cast Iron Kaminladen

Oven Grate 11 X 18 Cm As A Folding Fireplace Made Of Cast Iron Kaminladen

Fireplace Grate Cast Iron 450mm Bcsands Building And Landscape Supplies We Supply Sydney S Best

Liberty Foundry 24 In Cast Iron Heavy Duty Fireplace Grate With 4 Clearance G800 Bx The Home Depot

Replacement Grates For Cast Iron Fireplaces