Understanding and Choosing Fireplace Brick Liners

Fireplace brick liners are vital components of a functional and safe fireplace. These liners, typically made of fire-resistant brick, are installed within the firebox of a fireplace to protect the surrounding structure from the intense heat generated by burning fuel. Understanding the purpose, types, installation, and maintenance of fireplace brick liners is crucial for ensuring the longevity and safety of a fireplace system.

The primary function of a fireplace brick liner is to insulate the firebox, the area where the fire is built. Without a proper liner, the intense heat can directly impact the fireplace’s structure, potentially causing cracks, deterioration, and even combustion of nearby combustible materials. The liner effectively absorbs and reflects heat, reducing the risk of structural damage and increasing the overall efficiency of the fireplace.

Beyond safety, fireplace brick liners contribute to the aesthetic appeal of the fireplace. They come in various styles, colors, and textures, allowing homeowners to customize the look of their fireplace to match the overall décor of their home. From traditional red brick to more modern and decorative options, the choice of brick liner can significantly impact the visual impact of the fireplace.

Key Point 1: Types of Fireplace Brick Liners

Several types of fireplace brick liners are available, each with its own set of characteristics and benefits. Understanding the different options can help homeowners choose the best liner for their specific needs and preferences.

Firebrick: Firebrick is the most common type of fireplace brick liner. It is a dense and durable material specifically designed to withstand high temperatures. Firebrick is known for its excellent thermal properties and ability to retain heat, contributing to more efficient burning and heat distribution. It is typically available in standard sizes and shapes, making it relatively easy to install.

Refractory Mortar: While not a brick itself, refractory mortar is a crucial component in any brick liner system. This specialized mortar is designed to withstand high temperatures and is used to bind the bricks together, creating a strong and heat-resistant barrier. It's essential to use refractory mortar rather than standard mortar, which can crack and crumble under extreme heat.

Castable Refractory Cement: Castable refractory cement is a versatile option that can be molded into custom shapes and sizes. It is a mixture of cement and aggregates that hardens into a durable, heat-resistant material. This type of liner is often used to repair damaged fireboxes or to create unique fireplace designs. It can be more expensive and require specialized skills for proper installation.

Decorative Firebrick: These bricks are typically firebrick but with a decorative facing or design. They allow for greater aesthetic flexibility while maintaining the heat resistance properties required for a safe fireplace. They can include patterns, textures, or varying colors.

Key Point 2: Installation of Fireplace Brick Liners

Proper installation is critical to the performance and longevity of a fireplace brick liner. Incorrect installation can compromise the liner's ability to protect the fireplace structure and may even create safety hazards. While some homeowners may attempt a DIY installation, professional installation is often recommended, especially for complex projects.

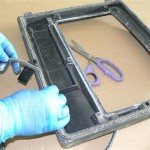

The installation process typically involves removing the old or damaged liner (if applicable), cleaning the firebox, and applying refractory mortar to the back of each brick. The bricks are then carefully positioned and pressed into place, ensuring a tight and even fit. Proper spacing and alignment are essential for creating a durable and aesthetically pleasing liner. After the bricks are installed, the mortar joints are filled and smoothed to create a seamless surface.

Using the correct type of mortar is crucial. Refractory mortar is specifically formulated to withstand high temperatures and will not crack or crumble like standard mortar. Furthermore, a sufficient amount of mortar should be used to fully adhere the bricks to the firebox walls, preventing them from loosening or falling out over time. Allow the mortar to fully cure according to the manufacturer’s instructions before using the fireplace.

For castable refractory cement liners, a mold is typically created to match the desired shape of the firebox. The cement mixture is then poured into the mold and allowed to harden. Once hardened, the liner is installed within the firebox, ensuring a secure and proper fit.

Key Point 3: Maintenance and Repair of Fireplace Brick Liners

Regular maintenance and timely repairs are essential for keeping a fireplace brick liner in good condition. Over time, the liner may develop cracks, chips, or spalling, which can compromise its effectiveness and safety. Addressing these issues promptly can prevent more extensive damage and prolong the life of the liner.

Regular inspections are crucial for identifying potential problems early on. Look for cracks, loose bricks, or crumbling mortar. Small cracks can often be repaired with refractory mortar. Clean the area around the crack thoroughly, apply the mortar, and smooth it out. Larger cracks or damaged bricks may require replacement. Remove the damaged brick, clean the area, and install a new brick with refractory mortar.

Soot and creosote buildup can also affect the performance of a fireplace brick liner. These deposits can insulate the bricks, reducing their ability to reflect heat and potentially contributing to chimney fires. Regular cleaning with a wire brush can help remove these deposits and maintain the liner's effectiveness.

If the liner is severely damaged or deteriorated, it may need to be completely replaced. This is a more extensive project that is best left to a professional. A new liner will restore the fireplace's functionality and safety, ensuring that it can be enjoyed for years to come.

In summary, understanding the different types of liners, ensuring proper installation techniques, and performing regular maintenance are critical for maximizing the benefits and lifespan of a fireplace brick liner. These steps help ensure a safe, efficient, and aesthetically pleasing fireplace experience.

Bl42 Refractory Brick Liner Kit Direct Vent Gas Fireplaces

Fireplace Chamber Lining Panels Brick Bond Solutions

Fireplace Chamber Lining Panels Brick Bond Solutions

Fireplace Chamber Lining Panels Brick Bond Solutions

Tahoe Luxury 36 Inch Clean Face Direct Vent Fireplace Fine S Gas

Empire Dvp50cpwh Whitewashed Herringbone Brick Liner

Fireplace Inserts Everything You Need To Know Full Service Chimney

Exacta 42 Vent Free Firebox With Herringbone Brick Liner America S Hearth

Empire White Mountain Hearth Liner Herringbone Brick Dvp1sh Fireplaces Usa

Empire Ehl24 Ceramic Fiber Traditional Brick Liner

Related Posts