Drum Fireplace Kit: A Comprehensive Guide to Installation and Functionality

A drum fireplace kit presents a unique opportunity to create a captivating and functional outdoor heating source. Utilizing the durable and readily available structure of a repurposed steel drum, these kits offer a blend of rustic aesthetics and efficient heat production. This article seeks to provide a thorough understanding of drum fireplace kits, encompassing their components, installation process, operational aspects, and considerations for safety and maintenance. The aim is to equip potential users with the knowledge necessary to make informed decisions regarding the acquisition and use of such a kit.

The appeal of a drum fireplace stems from multiple factors. Its inherent industrial design can complement a variety of outdoor spaces, from patios and decks to larger garden areas. The sheer size of the drum allows for a substantial fire, providing ample warmth during cooler evenings. Furthermore, the upcycling aspect resonates with environmentally conscious individuals, offering a sustainable alternative to purchasing a brand-new fireplace. Finally, drum fireplace kits typically offer a cost-effective solution compared to professionally built or traditionally manufactured outdoor fireplaces.

Understanding the Components of a Drum Fireplace Kit

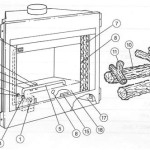

A typical drum fireplace kit includes several key components that are essential for safe and efficient operation. The foundational element is the drum itself, usually a standard 55-gallon steel drum. This drum may be supplied either raw or with a heat-resistant coating applied. Alongside the drum, the kit typically contains a pre-cut door and a door frame that are designed to be welded or bolted onto the drum. This door facilitates access for adding fuel and allows for controlling the airflow to manage the intensity of the fire.

Another crucial component is the chimney or flue. This element is responsible for directing smoke and fumes away from the immediate vicinity of the fireplace and ensures proper ventilation. The chimney usually comes in sections that can be assembled and attached to the top of the drum. The method of attachment can vary depending on the kit, ranging from simple clamping systems to more robust welding solutions. A rain cap is often included to prevent rainwater from entering the chimney and potentially damaging the fire.

Furthermore, a grate or fire basket is a standard inclusion in most kits. This grate elevates the firewood above the bottom of the drum, promoting airflow beneath the wood and facilitating more complete combustion. This improved airflow results in a hotter and cleaner-burning fire, reducing the amount of smoke produced. Some kits also include a spark screen or mesh to cover the front opening, preventing embers from escaping and potentially causing a fire hazard. Finally, some kits may include additional decorative elements or accessories, such as handles, stands, or protective covers.

The Installation Process: A Step-by-Step Guide

The installation of a drum fireplace kit requires careful planning and execution. The initial step involves preparing the drum itself. If the drum is unpainted, it is recommended to apply a heat-resistant paint to the exterior to protect it from rust and corrosion. This paint should be specifically formulated for high-temperature applications. If the drum has previously contained materials, it is imperative to thoroughly clean and decontaminate it to remove any residual substances that could be hazardous when heated. Proper safety precautions, including wearing protective gloves and eye protection, should be observed during this cleaning process.

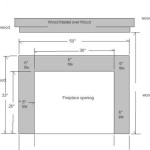

Next, the door opening needs to be cut into the drum according to the dimensions provided in the kit instructions. A cutting tool such as an angle grinder with a cutting wheel or a plasma cutter can be used for this purpose. After cutting the opening, the door frame should be attached to the drum. Depending on the kit, this may involve welding the frame to the drum or bolting it in place using pre-drilled holes. Welding provides a stronger and more permanent connection, while bolting offers a more readily reversible option.

The subsequent step involves assembling and attaching the chimney. The chimney sections should be connected according to the manufacturer's instructions, ensuring a secure and airtight seal between each section. The chimney is then attached to the top of the drum, typically using a clamp or a welding process. Ensuring a proper seal between the chimney and the drum is critical for preventing leaks of smoke and fumes. The rain cap is then installed at the top of the chimney to protect against rainwater intrusion.

Finally, the grate or fire basket is placed inside the drum at the bottom. The spark screen, if included, should be attached to the front of the door opening. It is crucial to thoroughly inspect all connections and attachments to ensure they are secure and properly aligned before using the fireplace. A test burn in a controlled environment is recommended to verify the proper functioning of the fireplace and identify any potential issues before regular use.

Operational Considerations and Safety Precautions

Operating a drum fireplace requires adherence to certain guidelines to ensure safety and efficiency. The fireplace should always be placed on a non-combustible surface, such as concrete, brick, or stone. A safe distance should be maintained between the fireplace and any combustible materials, such as fences, trees, or buildings. It is essential to consult local regulations and ordinances regarding open fires before using the fireplace.

Only seasoned firewood should be used as fuel in the fireplace. Green or wet wood produces excessive smoke and reduces the efficiency of the fire. The firewood should be stacked in a manner that allows for proper airflow around the logs. Overloading the fireplace with fuel should be avoided, as this can lead to excessive heat and potentially dangerous conditions. Kindling and small pieces of wood should be used to start the fire, gradually adding larger logs as the fire establishes itself.

The fire should never be left unattended. A responsible adult should always be present to monitor the fire and ensure that it is contained within the fireplace. A fire extinguisher or a readily available water source should be kept nearby in case of emergency. When extinguishing the fire, it is important to ensure that all embers are completely extinguished before leaving the area. This can be achieved by dousing the embers with water and stirring them thoroughly.

Regular maintenance is crucial for ensuring the longevity and safe operation of the drum fireplace. The chimney should be inspected regularly for creosote buildup, which can pose a fire hazard. Creosote should be removed periodically using a chimney brush. The grate or fire basket should be cleaned of ashes and debris after each use. The exterior of the drum should be inspected for rust or corrosion and treated accordingly. If the fireplace is not in use, it should be covered with a protective cover to prevent moisture and debris from accumulating inside.

The choice of drum fireplace kit, the carefulness of its installation, and the disciplined practice of safety precautions are the cornerstones of a rewarding experience. By paying attention to these details, one can enjoy the warmth and ambiance of a drum fireplace for years to come, while minimizing the risk of accidents or damage.

Bsk1000 Barrel Camp Stove Kit Us Company

Gtc Cast Iron Barrel Stove Kit Camp Farm Drum Wood Heater Fireplace Converter 9355764001642

Us Stove Barrel Camp Kit Bsk1000 The Home Depot

Making A Barrel Stove Using The Kit

55 Gallon Drum Barrel Stove Kit To Create A Camping Or Cook

Barrel Wood Stove Kit Diy Fireplace

Us Stove Cast Iron Barrel Adapter Kit Double Camp Compatible At Tractor Supply Co

Discontinued Vogelzang Standard Barrel Stove Kit Bk100e

Vogelzang Deluxe Barrel Stove Kit Wood Fireplace

55 Gallon Drum Barrel Stove Kit To Create A Camping Or Cook

Related Posts