DIY Propane Fireplace Insert: A Comprehensive Guide

Creating a propane fireplace insert through DIY methods presents a cost-effective alternative to purchasing pre-fabricated units. This endeavor, while rewarding, necessitates a thorough understanding of propane gas systems, combustion principles, and safety regulations. Comprehensive planning, meticulous execution, and adherence to relevant codes are paramount to ensuring a safe and functional fireplace insert.

This article provides a detailed guide to constructing a DIY propane fireplace insert, focusing on crucial aspects from initial planning to final installation. It encompasses material selection, burner system design, safety considerations, and testing procedures. This information is intended for individuals with prior experience in gas fitting, metal fabrication, and home improvement projects. Novices are strongly advised to seek professional assistance.

Understanding Propane Gas Systems and Safety

Propane, also known as liquefied petroleum gas (LPG), is a highly flammable hydrocarbon. Its combustion produces heat, water vapor, and carbon dioxide. However, incomplete combustion can result in the formation of carbon monoxide, a colorless, odorless, and deadly gas. Therefore, a properly designed and installed propane fireplace insert must ensure complete combustion and adequate ventilation.

Safety is the foremost consideration in any DIY propane project. Any leak can potentially lead to explosions. Strict adherence to all local and national codes pertaining to propane gas installations is mandatory. Consult with local building departments regarding permit requirements, inspection protocols, and applicable regulations. Gas line installation, testing, and appliance hookup are often regulated and might necessitate professional licensing.

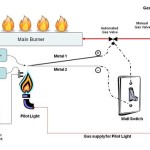

Critical safety components include a propane gas regulator, a shut-off valve, and a carbon monoxide detector. The regulator maintains a constant and safe gas pressure to the burner. The shut-off valve allows for immediate termination of the gas supply in case of emergencies. The carbon monoxide detector provides an early warning of hazardous gas levels.

Prior to commencing any work, a thorough understanding of propane's properties and potential hazards is essential. This includes knowledge of leak detection methods (using a soap and water solution), the proper handling of propane cylinders, and emergency procedures. Always disconnect the propane supply and ensure adequate ventilation before starting any modifications or repairs. Never smoke or use open flames near propane systems.

Designing the Burner System and Framework

The burner system is the heart of the propane fireplace insert. It must be designed to effectively mix propane and air to achieve complete combustion. There are several burner designs available, ranging from simple pipe burners with drilled holes to more sophisticated venturi burners. The choice depends on the desired heat output, flame characteristics, and available resources.

A common DIY approach involves using a length of black iron pipe as the burner. Holes are drilled along the pipe to allow propane to escape and mix with air. The size and spacing of the holes influence the flame pattern and heat output. Experimentation with different hole sizes and arrangements may be required to achieve the desired results. A venturi system can be incorporated to improve air-fuel mixing, leading to more efficient and cleaner combustion.

The fireplace insert's framework is primarily constructed from steel. Its design must accommodate the burner system, propane connection, and venting system. The framework must be sturdy enough to support the weight of the insert and withstand the heat generated by the flames. Steel tubing or angle iron is commonly used for the frame, while sheet metal can be used for the enclosure.

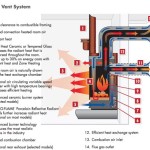

The design should incorporate adequate ventilation to ensure a constant supply of fresh air for combustion. This is crucial for complete combustion and the prevention of carbon monoxide buildup. Air inlets can be strategically placed at the bottom of the insert to allow air to flow freely around the burner. The framework also needs to incorporate brackets or mounting points to secure the insert within the existing fireplace opening.

Consider the aesthetics of the design. The visible portion of the insert can be customized with decorative elements, such as fire-resistant glass, ceramic logs, or rock wool. These elements should be carefully selected to withstand high temperatures and not impede airflow or combustion. Ensure there is adequate clearance between the burner and any decorative elements to prevent overheating or damage.

Fabrication, Installation, and Testing

Once the design is finalized, the fabrication process can begin. This involves cutting, welding, and assembling the steel framework and burner system. Precision is crucial during fabrication to ensure proper fitment and functionality. All welds should be strong, leak-proof, and properly cleaned to prevent corrosion.

The propane gas line should be installed by a qualified technician. This is a critical step, as any leaks can pose a significant safety hazard. The technician will ensure that the gas line is properly sized, connected, and tested for leaks. A gas pressure regulator should be installed to maintain a consistent gas pressure to the burner.

After the framework and burner system are assembled, a thorough leak test is essential. This is typically performed using a soap and water solution. The solution is applied to all gas connections, and any bubbles indicate a leak. Leaks must be repaired immediately before proceeding. Once pressure testing is complete, the insert is secured within the fireplace opening.

The venting system is a critical component of a propane fireplace insert. It is responsible for removing combustion products, such as carbon dioxide and water vapor, from the building. The venting system must be properly sized and installed according to local codes and manufacturer's specifications. Improper venting can lead to carbon monoxide buildup and pose a serious health hazard. Direct-vent systems, which draw combustion air from outside and exhaust combustion products to the outside, are often preferred for DIY installations.

Comprehensive testing is mandatory after installation. This includes checking the flame pattern, heat output, and carbon monoxide levels. A carbon monoxide detector should be installed in the vicinity of the fireplace insert to provide ongoing monitoring. The fireplace insert should be operated for an extended period to ensure proper functionality and safety. Monitor flame quality. A blue flame indicates efficient, complete combustion. Yellow or orange flames can indicate incomplete combustion, which could indicate a potential safety hazard.

Document every step of the project, including design specifications, material costs, and installation procedures. This documentation will be valuable for future maintenance, repairs, and inspections. Furthermore, it might be required for obtaining permits or demonstrating compliance with local codes.

The DIY propane fireplace insert project is complex and potentially dangerous. Proceed with caution and prioritize safety above all else. Seek professional assistance when needed, and never compromise on quality or safety standards. A well-designed and properly installed propane fireplace insert can provide years of warmth and enjoyment, but only if it is built and maintained with the utmost care and attention to detail.

How To Build An Outdoor Gas Fireplace Fireplaces Direct Learning Center

How To Install A Gas Fireplace Insert This Old House

10 Unique Propane Natural Gas Fireplace Inserts Insert Indoor

Installing A Gas Fireplace

How To Install A Fireplace Insert Diy Save Money

Your Guide To The Top Fireplace Inserts

I Built A Fireplace Easier Than Thought

How Much Does A Gas Fireplace Insert Cost Forbes Home

How To Modernize And Update A Gas Fireplace We Love Fire

How To Install A New Gas Fireplace Insert This Old House

Related Posts