DIY Cast Stone Fireplace Surround: A Comprehensive Guide

A fireplace serves as a focal point in many homes, offering warmth and aesthetic appeal. While factory-made fireplace surrounds are readily available, creating a cast stone surround through a do-it-yourself project offers a personalized and cost-effective alternative. This article details the process of constructing a cast stone fireplace surround, covering design considerations, material selection, mold creation, casting techniques, and installation procedures.

Planning and Design Considerations

The initial stage of a DIY cast stone fireplace surround project involves meticulous planning and design. A well-defined design serves as the blueprint for the entire process, ensuring that the final product meets the desired aesthetic and functional requirements. This phase encompasses several key considerations, including style, dimensions, code compliance, and structural integrity.

Style Selection: The style of the fireplace surround should complement the existing architectural style of the room. Options range from traditional to contemporary, each requiring different mold designs and casting techniques. Traditional styles often incorporate intricate details and classical motifs, while contemporary designs favor clean lines and minimalist aesthetics. Consider researching various fireplace surround styles to find inspiration and determine the most suitable option for the space.

Dimensional Accuracy: Accurate measurements are critical for a successful outcome. Begin by measuring the existing fireplace opening and the surrounding wall space. The dimensions of the new surround must be precisely determined to ensure a proper fit and avoid any structural issues. Account for the thickness of the cast stone material and any desired overhangs or reveals. It is advisable to create detailed scaled drawings that include all dimensions, profiles, and joint locations.

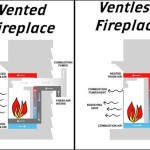

Code Compliance: Before commencing construction, verify local building codes and regulations concerning fireplace installations. These codes typically address clearances to combustible materials, hearth extensions, and chimney requirements. Adhering to these codes is essential for safety and legal compliance. Contact the local building department for specific guidelines and permit requirements.

Structural Considerations: The weight of the cast stone surround necessitates careful consideration of the supporting structure. Ensure that the wall behind the fireplace is capable of bearing the additional load. If necessary, reinforce the wall with additional framing or supports. The design should also incorporate appropriate anchoring methods for securing the surround to the wall, preventing movement or detachment.

Material Selection and Mold Creation

The selection of appropriate materials and the creation of accurate molds are fundamental to producing a high-quality cast stone fireplace surround. The choice of casting mix and mold materials will significantly impact the appearance, durability, and longevity of the finished product.

Casting Mix Formulation: A typical cast stone mix consists of cement, aggregates, and admixtures. Portland cement is the primary binder, providing strength and durability. Aggregates, such as sand and crushed stone, add bulk and texture to the mix. Admixtures, such as plasticizers and pigments, can be added to improve workability, reduce water demand, and enhance the aesthetic appeal of the cast stone. The specific proportions of each ingredient will vary depending on the desired characteristics of the cast stone.

Mold Materials: The mold serves as the negative form into which the casting mix is poured. Common mold materials include wood, silicone rubber, and fiberglass. Wood molds are relatively inexpensive and easy to construct but may be less durable and accurate than other options. Silicone rubber molds offer excellent detail reproduction and flexibility but are more expensive. Fiberglass molds provide a balance of durability, accuracy, and cost-effectiveness. The choice of mold material will depend on the complexity of the design, the desired level of detail, and the budget constraints.

Mold Fabrication: The mold fabrication process involves creating a precise replica of the desired fireplace surround components. This can be achieved through various techniques, including woodworking, sculpting, and mold making. For complex designs, it may be necessary to create a pattern or model using clay, foam, or wood. The pattern is then used to create a master mold, which is subsequently used to produce multiple production molds. The mold should be designed with appropriate draft angles to facilitate easy removal of the cast stone components.

Reinforcement Considerations: Embedding reinforcement within the cast stone elements enhances structural integrity. Steel reinforcement bars (rebar) or wire mesh are commonly used to resist tensile stresses and prevent cracking. The reinforcement should be strategically placed within the mold before pouring the casting mix. Ensure that the reinforcement is properly covered by the cast stone mix to prevent corrosion.

Casting Techniques and Finishing

The casting process involves pouring the prepared casting mix into the mold, consolidating the material, and allowing it to cure. Proper casting techniques are essential for achieving a dense, uniform, and defect-free cast stone product. After the cast stone components are removed from the mold, finishing processes are employed to refine their appearance and texture.

Mixing and Pouring: The casting mix should be thoroughly mixed according to the manufacturer's instructions. The water-cement ratio is crucial for achieving the desired strength and workability. Overly wet mixes can lead to shrinkage and cracking, while overly dry mixes can be difficult to consolidate. The mix should be poured into the mold in layers, ensuring that each layer is properly compacted to eliminate air voids. Vibration is often employed to consolidate the mix and ensure that it fills all the intricate details of the mold.

Curing Process: Curing is the process of maintaining adequate moisture and temperature to allow the cement to hydrate and develop strength. The cast stone components should be protected from direct sunlight and extreme temperatures during the curing period. Covering the molds with plastic sheeting or burlap can help retain moisture. The curing period typically lasts for several days, depending on the type of cement and the ambient conditions.

Demolding and Finishing: Once the cast stone components have cured sufficiently, they can be carefully removed from the molds. The demolding process should be performed with caution to avoid damaging the cast stone or the mold. After demolding, the cast stone components may require finishing processes to refine their appearance. These processes can include grinding, sanding, polishing, and staining. Grinding removes any imperfections or blemishes from the surface. Sanding smooths the surface and prepares it for finishing. Polishing enhances the shine and luster of the cast stone. Staining can be used to adjust the color and texture of the cast stone to match the desired aesthetic.

Sealing and Protection: Applying a sealant to the finished cast stone components provides protection against moisture, stains, and weathering. The sealant should be compatible with the type of cast stone and should be applied according to the manufacturer's instructions. Regular cleaning and maintenance will help prolong the life and appearance of the cast stone fireplace surround.

Installation and Assembly

The final step in the DIY cast stone fireplace surround project involves installing and assembling the cast stone components around the fireplace opening. Proper installation techniques are essential for ensuring the stability, safety, and aesthetic appeal of the finished surround.

Surface Preparation: Before installing the cast stone surround, ensure that the substrate is clean, level, and structurally sound. Remove any loose or crumbling material from the wall surface. If necessary, apply a leveling compound to create a smooth and even surface. Check that the fireplace opening is properly aligned and square.

Adhesive Selection and Application: Selecting the appropriate adhesive is crucial for bonding the cast stone components to the wall. Masonry adhesives, such as thin-set mortar or construction adhesive, are commonly used for this purpose. The adhesive should be applied according to the manufacturer's instructions. Ensure that the adhesive is evenly distributed across the back of the cast stone components and that sufficient contact is made with the substrate.

Assembly and Alignment: Begin by installing the base components of the fireplace surround, such as the hearth and the legs. Use shims to ensure that the components are level and plumb. Apply adhesive to the back of the remaining components and carefully position them around the fireplace opening. Use a level and a square to ensure that the components are properly aligned. Secure the components with temporary supports until the adhesive has fully cured.

Jointing and Finishing: After the adhesive has cured, fill the joints between the cast stone components with a matching grout or caulk. The grout should be applied smoothly and evenly, and any excess material should be wiped away. After the grout has cured, inspect the entire fireplace surround for any imperfections or blemishes. Touch up any damaged areas with matching paint or stain. Finally, clean the entire surface of the fireplace surround to remove any dust or debris.

Diy Faux Cast Stone Fireplace Part 1 Demo And Tiling The Hearth Top Shelf

Diy Faux Cast Stone Fireplace Part 2 Building The Mantel Top Shelf

Diy Faux Plaster Fireplace Surround Chelsey Freng

Diy Faux Plaster Fireplace Surround Chelsey Freng

Diy Faux Cast Stone Fireplace Part 1 Demo And Tiling The Hearth Top Shelf

Diy Faux Cast Stone Fireplace Part 3 Mounting Our Tv Top Shelf

Cast Stone Fireplaces So Much Better With Age

Diy Fireplace Mantel Surround Faux Cast Stone European Style Tidbits

How To Elevate Your Living Room Diy Faux Cast Stone Fireplace Hometalk

Diy Fireplace Mantel Surround Faux Cast Stone European Style Tidbits

Related Posts