Direct Vent Gas Fireplace Requirements: A Comprehensive Guide

Direct vent gas fireplaces have become a popular choice for homeowners seeking the ambiance of a fireplace without the mess and inefficiency of traditional wood-burning models. These fireplaces offer a closed combustion system, drawing air from outside the home for combustion and venting exhaust gases directly outdoors through a sealed vent system. This design enhances safety, efficiency, and air quality compared to older fireplace technologies. However, proper installation and operation depend on adherence to specific requirements regarding location, venting, gas supply, and safety features. Understanding these requirements is essential for ensuring a safe, reliable, and efficient heating appliance.

This article provides a comprehensive overview of the crucial requirements for installing and operating a direct vent gas fireplace, covering key aspects from location considerations to mandated safety mechanisms.

Location and Clearances

The physical location of a direct vent gas fireplace within a home significantly impacts its performance, safety, and compliance with building codes. Considerations must be given to both indoor clearances and outdoor vent termination points.

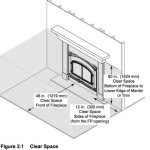

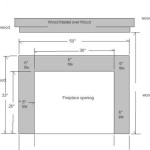

Indoor clearances refer to the minimum distances required between the fireplace unit and combustible materials. These clearances are specified by the manufacturer and are crucial for preventing fire hazards. Common combustible materials include wood framing, drywall, furniture, and fabrics. The manufacturer’s installation manual will detail specific clearance requirements for the sides, top, rear, and front of the fireplace. Failure to adhere to these clearances can lead to overheating and potential ignition of nearby materials.

Clearances also extend to the hearth. While direct vent fireplaces produce significantly less radiant heat than wood-burning fireplaces, some models still require a non-combustible hearth extension in front of the unit. The size and composition of the hearth extension will be specified in the manufacturer’s instructions. The hearth serves to protect flooring from potential sparks or embers, although this is less of a concern with gas fireplaces compared to wood-burning alternatives. Compliance with hearth requirements is essential for a safe installation.

In addition to indoor clearances, outdoor vent termination locations are heavily regulated. The vent terminus, which is the point where exhaust gases are expelled from the building, must be located a safe distance from windows, doors, air intakes, and other building openings. This is to prevent exhaust gases from re-entering the home or neighboring properties. Minimum distances are typically specified in local building codes and the manufacturer’s installation instructions. Codes often mandate a minimum horizontal and vertical distance from windows and doors, as well as a minimum height above grade.

Particular attention must be paid to the proximity of the vent terminus to decks, balconies, and overhangs. Gases can accumulate under these structures, creating a potential safety hazard. Venting requirements may necessitate extending the vent further upward to clear these obstructions. Also, consider prevailing wind patterns in the area. Locating the vent on the leeward side of the building during common wind conditions can help to prevent exhaust gases from being blown back towards the home.

Accessibility for maintenance is another factor. The location should allow for easy access to the fireplace and venting system for inspection, cleaning, and repair. This includes ensuring sufficient space around the unit for a technician to work comfortably and safely. Consideration should also be given to future servicing needs when selecting the location.

Venting System Requirements

The venting system is a critical component of a direct vent gas fireplace, responsible for safely exhausting combustion gases to the outdoors. These systems are specifically designed for direct vent applications and must meet stringent safety and performance standards. Using incorrect venting components or deviating from the manufacturer’s instructions can create serious safety hazards, including carbon monoxide poisoning.

Direct vent fireplaces utilize a co-axial or co-linear venting system. Co-axial systems feature a pipe within a pipe; the inner pipe exhausts combustion gases, while the outer pipe draws in fresh air for combustion. Co-linear systems use two separate pipes, one for intake air and one for exhaust. Both types create a sealed system that minimizes the risk of indoor air contamination.

The vent pipe itself must be specifically listed and approved for use with direct vent gas fireplaces. Common materials include stainless steel and aluminum. The type and size of vent pipe are determined by the fireplace manufacturer and are based on the fireplace's BTU input, the venting configuration, and the overall vent length. The manufacturer’s installation manual will specify the exact vent pipe requirements.

Vent length is a critical factor. Direct vent fireplaces have minimum and maximum vent length limitations. The minimum vent length ensures adequate draft and prevents flame instability. The maximum vent length is determined by the fireplace's ability to push exhaust gases through the system. Exceeding the maximum vent length can lead to incomplete combustion and carbon monoxide buildup.

Vent rise and run also impact performance. The vent system must have a sufficient vertical rise to create a natural draft. The manufacturer's instructions will specify the minimum and maximum allowable horizontal run. Excessive horizontal run can impede the flow of exhaust gases. The number and type of elbows used in the venting system are also crucial. Each elbow adds resistance to the flow of exhaust gases, and excessive elbows can reduce the fireplace's efficiency and increase the risk of carbon monoxide production.

Proper sealing of the vent joints is essential. Vent pipes are typically joined using a slip-fit connection with a sealant or gasket. The sealant or gasket must be approved for use with the vent pipe material and must be applied correctly to create a gas-tight seal. Any leaks in the venting system can allow exhaust gases to escape into the home. Regular inspection of the vent system is recommended to ensure that all connections remain tight and leak-free.

Vent termination caps are designed to prevent rain, snow, and debris from entering the venting system. The termination cap must be specifically designed for use with direct vent fireplaces and must be installed according to the manufacturer’s instructions. The cap should be positioned to prevent downdrafts and to ensure that exhaust gases are dispersed effectively.

Gas Supply and Safety Devices

A direct vent gas fireplace requires a reliable and properly sized gas supply to function safely and efficiently. This involves understanding the gas type (natural gas or propane), pressure requirements, and proper connection procedures. Furthermore, incorporating mandated safety devices is non-negotiable for the protection of occupants.

The first step is to determine the gas type available at the installation location. Direct vent fireplaces are designed to operate on either natural gas or propane. Using the incorrect fuel type can result in improper combustion, reduced efficiency, and potential safety hazards. The fireplace will be clearly labeled with the required fuel type. Conversion kits are available for some models to switch between natural gas and propane, but these conversions must be performed by a qualified technician.

Gas pressure is another critical factor. The fireplace requires a specific gas pressure to operate correctly. The manufacturer's installation manual will specify the required gas pressure, typically measured in inches of water column (WC). The gas supply line must be capable of delivering gas at the required pressure. A qualified gas fitter should measure the gas pressure at the appliance connection to ensure that it meets the manufacturer's specifications. If the gas pressure is too low, the fireplace may not operate correctly. If the gas pressure is too high, it can damage the appliance.

The gas supply line must be properly sized to provide an adequate flow of gas to the fireplace. The size of the gas supply line is determined by the fireplace's BTU input and the length of the gas line. A qualified gas fitter can calculate the appropriate gas line size using industry-standard methods. Undersized gas lines can restrict the flow of gas, leading to poor fireplace performance.

The gas connection to the fireplace must be made by a qualified gas fitter in accordance with local codes and regulations. The connection should be made using approved fittings and materials. A shut-off valve must be installed upstream of the fireplace to allow for easy isolation of the gas supply during maintenance or emergencies. The shut-off valve should be readily accessible.

Several safety devices are mandatory for direct vent gas fireplaces. A flame sensor or thermocouple is designed to shut off the gas supply if the pilot light is extinguished or if the flame goes out. This prevents unburned gas from accumulating in the home. A pressure regulator maintains a constant gas pressure to the burner, regardless of fluctuations in the gas supply pressure. This ensures stable and consistent combustion. A carbon monoxide detector should be installed in the vicinity of the fireplace to provide an early warning of carbon monoxide leaks. Regular testing of the carbon monoxide detector is essential.

Some fireplaces also incorporate additional safety features, such as overheat sensors and automatic shut-off mechanisms. These features are designed to protect the appliance and prevent potential hazards. Regular inspection and maintenance of these safety devices are crucial for ensuring their proper functioning.

Strict adherence to all gas supply and safety device requirements is paramount for the safe and reliable operation of a direct vent gas fireplace. Improper installation or maintenance can create serious safety hazards, including gas leaks, explosions, and carbon monoxide poisoning. Always consult with a qualified professional for any gas supply or safety-related work.

Understanding How Direct Vent Works Heat Glo

What Is A Direct Vent Fireplace Fireplaces Learning Center

.aspx?strip=all)

Benefits Of Direct Vent Fireplaces Regency Fireplace S

Benefits Of Direct Vent Fireplaces

What Are The Best Ways To Vent A Gas Fireplace Zoroast

Gas Fireplace Venting Explained Heat Glo

Gas Fireplaces Direct Vent Vs Free Fine Homebuilding

Gas Fireplace Venting Explained Heat Glo

Direct Vent B Gas Free S Mazzeo Stoves Fireplaces

Direct Vent Vs Natural Www Mygasfireplacerepair Com

Related Posts