Corner Ventless Gas Fireplace Insert: A Comprehensive Guide

A corner ventless gas fireplace insert offers a compelling heating and aesthetic solution for many homeowners. Unlike traditional fireplaces, these inserts do not require a chimney or venting system, providing installation flexibility and potentially lower installation costs. This absence of a chimney simplifies the setup process and allows for placement in areas where a conventional fireplace would be impractical. Understanding the intricacies of corner ventless gas fireplace inserts, including their operation, safety features, installation requirements, and maintenance needs, is crucial before making a purchase.

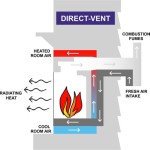

Ventless gas fireplaces, also known as vent-free or unvented fireplaces, operate by burning natural gas or propane within a contained unit. A key characteristic of these fireplaces is their reliance on oxygen from the room they occupy, and their emission of combustion byproducts, primarily carbon dioxide and water vapor, back into the living space. Because of these combustion byproducts, safety considerations are paramount when considering a ventless system.

Corner placement presents a unique opportunity for ventless gas fireplaces. Utilizing a corner maximizes space while creating a focal point within a room. The visual impact of a fire burning in a corner can be particularly appealing, adding warmth and ambiance to the area. The design of corner ventless gas fireplace inserts often incorporates features that enhance the visual appeal from multiple viewing angles, such as realistic log sets and adjustable flame settings.

Key Point 1: Understanding Ventless Technology and Safety

The core of a ventless gas fireplace insert lies in its oxygen depletion sensor (ODS). This sensor is a critical safety component designed to monitor the oxygen levels in the room. If the oxygen level drops below a predetermined threshold, indicating insufficient ventilation, the ODS automatically shuts off the gas supply to the fireplace, preventing the buildup of carbon monoxide. The function of this sensor is essential for ensuring the safety of occupants in the room.

Carbon monoxide (CO) is a colorless, odorless gas produced by incomplete combustion. Exposure to high concentrations of CO can be fatal. While ventless fireplaces are designed to minimize CO production through efficient combustion, proper ventilation is still necessary to ensure safe operation. Regularly inspecting and maintaining the ODS is crucial to ensure it functions correctly. Homeowners should also install and maintain carbon monoxide detectors throughout their homes, particularly near sleeping areas.

Beyond the ODS, other safety features often incorporated into ventless gas fireplace inserts include automatic shut-off mechanisms that activate in the event of a gas leak or pilot light failure. These features enhance the overall safety profile of the appliance. It's important to select a unit that has been tested and certified by a recognized testing laboratory, such as CSA or UL. These certifications indicate that the fireplace meets established safety standards.

Local regulations often govern the use of ventless gas fireplaces. Some jurisdictions may restrict or prohibit their installation due to concerns about indoor air quality and safety. Before purchasing a ventless gas fireplace insert, it's essential to consult with local building codes and obtain any necessary permits. These regulations may dictate specific requirements for room size, ventilation, and installation practices.

Ventilation is essential even with a ventless system. While the unit doesn't require a chimney, adequate airflow in the room is crucial to prevent the buildup of combustion byproducts. Building codes and manufacturer recommendations often specify minimum room sizes and ventilation requirements for ventless gas fireplaces. This could include leaving a window slightly open or ensuring sufficient airflow from other parts of the house.

Key Point 2: Installation Considerations for Corner Units

Installing a corner ventless gas fireplace insert requires careful planning and adherence to manufacturer instructions and local building codes. While the absence of a chimney simplifies the process compared to traditional fireplaces, proper installation is still critical for safe and efficient operation. The first step involves preparing the corner where the insert will be placed. This may involve framing, leveling the floor, and ensuring adequate clearances from combustible materials.

Clearance requirements are crucial for preventing fire hazards. These requirements specify the minimum distances that combustible materials, such as wood framing, drywall, and furniture, must be kept away from the fireplace insert. Manufacturer instructions provide detailed specifications for clearance requirements, which must be strictly followed. Failure to adhere to these clearances can create a significant fire risk.

Gas line connections must be performed by a qualified professional. Whether the fireplace uses natural gas or propane, the gas line connection must be performed by a licensed plumber or gas fitter. This ensures that the connection is made safely and complies with local codes. Improper gas line connections can lead to gas leaks, which pose a serious safety hazard. After the gas line connection is made, it should be thoroughly tested for leaks using a gas leak detector.

Electrical connections may also be required, depending on the fireplace model. Some ventless gas fireplace inserts incorporate features that require electrical power, such as electronic ignition, remote control, or a blower fan. These connections must be made in accordance with electrical codes. Using a ground fault circuit interrupter (GFCI) outlet is recommended to protect against electrical shock.

Aesthetics also play a crucial role in corner installations. Corner units often require custom framing and finishing to seamlessly integrate them into the room's design. The choice of materials and finishes should complement the existing decor and create a visually appealing focal point. Consider factors such as the size of the room, the style of the furniture, and the overall ambiance you wish to create.

Accessibility for maintenance is something that should also be considered during installation. While ventless gas fireplaces require less maintenance than traditional fireplaces, regular inspections and cleaning are still necessary. Ensure that the fireplace is easily accessible for routine maintenance tasks, such as cleaning the burner and checking the ODS. Planning for accessibility during installation can simplify future maintenance efforts.

Key Point 3: Maintenance and Operational Best Practices

Proper maintenance is essential for ensuring the safe and efficient operation of a corner ventless gas fireplace insert. Regular inspections and cleaning can help prevent malfunctions and extend the lifespan of the appliance. A consistent maintenance schedule will also guarantee the system’s safety and reliability.

Regularly cleaning the burner and surrounding area is important to prevent a buildup of dust and debris. This build-up can interfere with the proper combustion of gas, leading to incomplete combustion and increased levels of carbon monoxide. Use a soft brush or vacuum cleaner to remove any debris from the burner and pilot light area. Consult the manufacturer's instructions for specific cleaning recommendations.

The ODS should be inspected periodically to ensure it is functioning correctly. Check for any signs of damage or corrosion. If the ODS is not functioning properly, it should be replaced immediately. The ODS is a critical safety component, and its proper functioning is essential for preventing carbon monoxide poisoning. Many manufacturers recommend annual professional servicing of the unit to ensure the ODS and other safety features are working correctly.

Ventilation is also critical. Even with the ODS, adequate ventilation is crucial for ensuring safe operation. Avoid blocking air vents and ensure that windows and doors can be opened to allow fresh air into the room. Be particularly mindful of ventilation when using the fireplace for extended periods. Consider using a fan to circulate air within the room and promote better ventilation.

Monitor the flame characteristics of the fireplace. A yellow or flickering flame can indicate incomplete combustion and the potential for increased carbon monoxide production. If you notice any unusual flame characteristics, turn off the fireplace and contact a qualified service technician. Proper flame characteristics are an indicator of efficient combustion and safe operation.

Carefully consider the placement of flammable materials near the fireplace. Never place combustible materials, such as curtains, furniture, or paper, too close to the fireplace. Adhere to the clearance requirements specified by the manufacturer. Keep a fire extinguisher nearby in case of a fire. The prevention of fire is a critical safety consideration.

Finally, ensure carbon monoxide detectors are installed and functioning correctly. Test the detectors regularly to ensure they are operational. Replace batteries as needed. Carbon monoxide detectors provide an important layer of protection against the dangers of carbon monoxide poisoning. Properly functioning detectors can provide an early warning of dangerous CO levels, allowing occupants to evacuate the premises.

Corner Ventless Gas Fireplace Visualhunt

Corner Ventless Gas Fireplace Visualhunt

24 Vail Standard Corner Cabinet Mantel Built In Base Empire

Procom Heating Dual Fuel Ventless Gas Fireplace System With Corner Combo Mantel 10 000 Btu T Stat Control 170061 The Home Depot

Corner Ventless Gas Fireplace Visualhunt

Corner Ventless Gas Fireplace Visualhunt

Procom Heating Dual Fuel Ventless Gas Fireplace System With Corner Combo Mantel 10 000 Btu T Stat Control 170061 The Home Depot

Corner Two Sided Gas Fireplace Heat Glo

Design Specialties 36 Compact 20 000 Btu Vent Free Liquid Pro Us Fireplace

Duluth Forge 41 75 In Black Ventless Natural Or Liquid Propane Gas Fireplace The Fireplaces Department At Com

Related Posts