Coal Fireplace Inserts: A Comprehensive Guide

Coal fireplace inserts offer a unique heating solution for homeowners seeking an alternative to traditional wood-burning fireplaces. These inserts are designed to fit directly into an existing fireplace opening, providing a more efficient and controlled method of burning coal for home heating. Understanding the functionality, benefits, and considerations associated with coal fireplace inserts is crucial for making an informed decision about their suitability for a particular home.

The primary function of a coal fireplace insert is to transform an existing, often inefficient, fireplace into a powerful and controllable heat source. Open fireplaces are notoriously inefficient, with a significant portion of the heat generated lost up the chimney. A coal insert, on the other hand, is designed to trap and radiate heat into the room, increasing overall heating efficiency. This is achieved through a sealed combustion chamber and often, a built-in blower fan that circulates warm air into the living space.

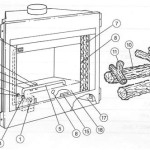

Coal fireplace inserts typically feature a cast iron or steel construction, chosen for their durability and heat retention properties. The design includes a grate system for burning coal, an ash pan for easy removal of combustion byproducts, and a door, often made of glass, to contain the fire and allow viewing of the flames. Advanced models may include thermostatic controls for maintaining a desired temperature and automatic combustion air controls for optimizing fuel efficiency.

Key Point 1: Understanding the Benefits of Coal Fireplace Inserts

Coal fireplace inserts offer several advantages over traditional wood-burning fireplaces. These benefits range from improved heating efficiency to increased convenience and control over the heating process.

One of the most significant benefits is improved heating efficiency. As previously mentioned, open fireplaces are inefficient due to heat loss up the chimney. Coal inserts, with their sealed combustion chambers and controlled airflow, drastically reduce this heat loss. The heat produced is effectively radiated into the room, providing a more consistent and comfortable temperature.

Another advantage is the longer burn time associated with coal. Coal burns at a higher temperature and for a longer duration than wood, requiring less frequent refueling. This is particularly beneficial for homeowners seeking a continuous heating solution, especially during colder months. The long burn time reduces the need for constant attention and maintenance of the fire.

Coal inserts also offer a greater degree of control over the heating process. Many models are equipped with adjustable air controls and thermostatic settings, allowing homeowners to regulate the intensity of the fire and maintain a desired room temperature. This level of control is not possible with open fireplaces, which offer limited adjustment capabilities.

Furthermore, coal burning, when controlled properly within a sealed appliance, can produce less creosote buildup in the chimney compared to wood burning. Creosote is a flammable byproduct of wood combustion that can accumulate in the chimney and pose a fire hazard. While coal does emit other pollutants, modern coal inserts are designed to minimize emissions and comply with environmental regulations.

Finally, the convenience factor of a coal fireplace insert should not be overlooked. The reduced need for frequent refueling and the integrated ash pan simplify the maintenance process. The sealed combustion chamber also reduces the risk of sparks and embers escaping into the room, enhancing safety.

Key Point 2: Factors to Consider Before Purchasing a Coal Fireplace Insert

Before investing in a coal fireplace insert, several factors require careful consideration. These factors include the type of coal to be used, the size of the insert relative to the fireplace opening, the ventilation requirements, and the cost of installation and operation. A thorough assessment of these factors is critical for ensuring a successful and satisfying experience.

The type of coal to be used is a primary consideration. Different types of coal, such as anthracite and bituminous, have varying heat outputs, burn rates, and emission characteristics. Anthracite coal is generally considered to be a cleaner-burning option, producing less smoke and soot than bituminous coal. However, it is also more expensive and may be harder to find in some regions. The chosen type of coal will directly impact the performance and maintenance requirements of the coal insert. It is essential to consult with a qualified professional to determine the most suitable type of coal for the specific insert model and local availability.

The size of the insert must be carefully matched to the dimensions of the existing fireplace opening. An improperly sized insert can lead to inefficient heating and potential safety hazards. The insert should fit snugly within the opening, with appropriate clearances maintained for ventilation and heat dissipation. Professional measurements are highly recommended to ensure a proper fit.

Proper ventilation is essential for safe and efficient operation. Coal combustion produces carbon monoxide, a colorless and odorless gas that can be fatal. A properly installed and maintained chimney liner is crucial for venting exhaust gases safely to the outside. Regular chimney inspections are necessary to ensure that the liner is intact and free from obstructions. Carbon monoxide detectors should be installed in the home to provide an early warning in case of a malfunction.

The cost of installation and operation is another important consideration. The initial cost of the insert can vary depending on the size, features, and brand. Installation costs can also be significant, particularly if modifications to the existing chimney or fireplace are required. The ongoing cost of coal must also be factored in, as well as the cost of regular maintenance and chimney cleaning. A detailed budget should be prepared to ensure that the cost of owning and operating a coal fireplace insert is within acceptable limits.

Finally, local regulations and building codes should be consulted before installing a coal fireplace insert. Some jurisdictions may have specific requirements for emissions, chimney height, and safety clearances. Obtaining the necessary permits and complying with local regulations is essential for avoiding legal issues and ensuring the safety of the installation.

Key Point 3: Installation and Maintenance of Coal Fireplace Inserts

Proper installation and regular maintenance are crucial for ensuring the safe and efficient operation of a coal fireplace insert. Improper installation can lead to hazardous conditions, while neglecting maintenance can reduce the insert's lifespan and increase the risk of malfunctions.

Installation should always be performed by a qualified professional with experience in installing coal-burning appliances. The installation process typically involves preparing the fireplace opening, installing the chimney liner, connecting the insert to the chimney, and testing the system for proper operation. A professional installer will be familiar with local building codes and safety regulations and will ensure that the installation is performed correctly.

The chimney liner is a critical component of the system and must be installed correctly to prevent the leakage of harmful gases into the home. The liner should be made of a material that is compatible with coal combustion, such as stainless steel. The liner should be properly insulated to prevent heat loss and reduce the risk of condensation. Regular inspections of the chimney liner are necessary to ensure that it is in good condition and free from cracks or damage.

Regular maintenance is essential for keeping the coal fireplace insert operating efficiently and safely. This includes cleaning the ash pan regularly to prevent ash buildup, inspecting the grate for damage, and cleaning the glass door to remove soot and creosote. The chimney should be inspected and cleaned annually by a qualified chimney sweep to remove creosote and other debris that can accumulate over time. A build-up of creosote is highly flammable and poses a fire hazard.

The air intakes and exhaust vents should be kept clear of obstructions to ensure proper combustion and ventilation. Dust and debris can accumulate over time and restrict airflow, reducing efficiency and increasing the risk of carbon monoxide buildup. The blower fan, if present, should be cleaned regularly to maintain its performance.

It is also important to follow the manufacturer's instructions for operating and maintaining the coal fireplace insert. The instruction manual provides valuable information on the proper use of the appliance, including recommendations for fuel type, airflow settings, and maintenance schedules. Adhering to these instructions will help to ensure the long-term performance and safety of the coal insert.

In addition to routine maintenance, it is important to schedule regular professional inspections of the coal fireplace insert and chimney. A qualified technician can identify potential problems before they become serious and can perform necessary repairs or adjustments to keep the system operating safely and efficiently. Professional inspections are particularly important for identifying issues with the chimney liner, which may not be visible during routine cleaning.

Belmont Small Gas Insert

Elite Fireplace Insert Legacy Stoves Coal Stove

Fireplaces Inserts Hillside Acres Stoves Coal Wood Propane

Fireplaces Inserts Hillside Acres Stoves Coal Wood Propane

Valor 530icn Coal Fire Radiant Gas Fireplace And Insert Installed With Polished Windsor Arch In Mantel Antique Mantels

Hitzer 983 Fireplace Insert

Keystoker Hf 70 90 Coal Insert By Obadiah S Woodstoves

Hitzer 503 Ez Flo Hopper Fed Fireplace Insert The Coal

Fireplace Insert

Pub 16 Inch Gas Coal Basket With Fireback