DIY Cinder Block Outdoor Fireplace: A Comprehensive Guide

Creating an outdoor fireplace can transform a backyard into a cozy and inviting gathering space. While professional installations can be costly, constructing a cinder block fireplace using a do-it-yourself approach offers an economical and customizable alternative. This article provides a detailed guide to building a cinder block outdoor fireplace, covering the necessary materials, tools, and construction steps.

Planning and Design Considerations

Before commencing any construction project, meticulous planning is crucial. The design phase involves several key considerations to ensure the fireplace meets safety standards, functionality requirements, and aesthetic preferences. Specifically, compliance with local building codes is paramount.

Local building codes often dictate specific regulations regarding outdoor fireplaces, including setback distances from property lines, required permits, and restrictions on fuel types. Researching and adhering to these codes will prevent potential legal issues and ensure the structure’s safety and longevity. Contacting the local building department or reviewing online resources specific to the municipality is recommended.

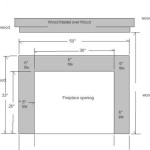

The size and style of the fireplace should be carefully considered. The dimensions will influence the material quantities required and the overall visual impact on the surrounding outdoor space. A larger fireplace might provide greater warmth and a more dramatic focal point, while a smaller design can be more discreet and suitable for smaller yards. Style choices range from rustic, using natural stone veneers or textured cinder blocks, to modern, employing smooth concrete surfaces and clean lines. A scale drawing or 3D rendering can help visualize the final product and refine the design before construction begins.

The placement of the fireplace is another critical factor. It should be located in an area that provides adequate ventilation to prevent smoke buildup and minimize the risk of carbon monoxide poisoning. Avoid placing the fireplace directly beneath overhanging trees or near flammable materials such as wooden fences or sheds. Consider prevailing wind patterns to minimize smoke drift towards seating areas or neighboring properties. Proximity to seating areas, patios, or decks should also be factored in to maximize usability and create a cohesive outdoor living space.

Materials and Tools Required

Constructing a cinder block fireplace requires a specific set of materials and tools to ensure structural integrity and a professional finish. The selection of materials should prioritize durability, weather resistance, and aesthetic appeal.

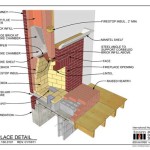

The primary building materials include cinder blocks, mortar mix, fire bricks, and gravel. Cinder blocks form the structural foundation and walls of the fireplace. The quantity will depend on the size and design of the fireplace. Mortar mix acts as the bonding agent between the cinder blocks, providing a strong and weather-resistant connection. Fire bricks are specifically designed to withstand high temperatures and line the firebox, protecting the surrounding cinder blocks from damage. Gravel is used to create a stable and well-drained base for the fireplace foundation.

Additional materials may include concrete mix for the foundation slab, rebar for reinforcing the foundation, a chimney liner to improve draft and prevent creosote buildup, and decorative stone or veneer to enhance the aesthetic appearance of the fireplace. The choice of decorative materials will depend on the desired style and budget.

The essential tools for the project include a mortar mixer or wheelbarrow, a shovel, a trowel, a level, a rubber mallet, a measuring tape, a circular saw with a masonry blade, a safety glasses, and work gloves. A mortar mixer is recommended for larger projects to ensure consistent mortar consistency. A shovel is used for digging and moving materials. A trowel is used for applying mortar. A level ensures that the cinder blocks are properly aligned and level. A rubber mallet is used to gently tap the cinder blocks into place. A measuring tape is used for accurate measurements. A circular saw with a masonry blade is used for cutting cinder blocks to size, although renting a masonry saw might be more efficient for extensive cutting. Safety glasses and work gloves are essential for protecting the eyes and hands during construction.

Construction Steps: A Step-by-Step Guide

The construction of a cinder block fireplace involves several key steps, each requiring precision and attention to detail. Following these steps carefully will ensure a structurally sound and aesthetically pleasing final product.

The first step is to prepare the foundation. This involves excavating the area where the fireplace will be located. The depth of the excavation will depend on the local frost line, but a minimum depth of 6 inches is generally recommended. After excavation, a layer of compacted gravel should be added to provide drainage and stability. A concrete slab should then be poured on top of the gravel, with rebar reinforcement for added strength. The concrete slab should be level and allowed to cure for at least 48 hours before proceeding to the next step.

The second step is to lay the first course of cinder blocks. This is a critical step that requires careful attention to ensure that the foundation is level and square. Mortar should be applied to the top of the concrete slab and the bottom of the cinder blocks. The cinder blocks should be carefully positioned and tapped into place with a rubber mallet. A level should be used to ensure that each cinder block is level and aligned with the adjacent blocks. Check for squareness by measuring the diagonals. Any discrepancies should be corrected at this stage before the mortar sets.

The third step is to continue laying the cinder blocks, course by course, until the desired height of the fireplace walls is reached. Mortar should be applied to the top of each course of cinder blocks and the bottom of the next course. Take care to stagger the joints between the cinder blocks to create a stronger and more stable wall. Use a level to ensure that each course is level and plumb. Periodically check the squareness of the walls as the construction progresses.

The fourth step is to construct the firebox. The firebox is the area where the fire will be built. It should be lined with fire bricks to protect the surrounding cinder blocks from the high temperatures. The fire bricks should be mortared in place, ensuring that the joints are tight and that the firebox is properly sealed. The dimensions of the firebox will depend on the desired size of the fire and the overall design of the fireplace.

The fifth step is to install the chimney liner. A chimney liner is a metal or ceramic tube that runs inside the chimney. It helps to improve draft, prevent creosote buildup, and protect the chimney from damage. The chimney liner should be properly sized for the fireplace and installed according to the manufacturer's instructions. The top of the chimney should be capped to prevent rain and debris from entering.

The sixth step is to add any desired decorative elements. This may include applying a stone veneer, stucco, or paint to the exterior of the fireplace. Concrete pavers or flagstone can be used to create a decorative hearth in front of the firebox. The choice of decorative elements will depend on the desired style and budget.

Ensuring Safety and Maintenance

Safety is of paramount importance when operating an outdoor fireplace. Following safety guidelines and performing regular maintenance will help prevent accidents and ensure the fireplace remains in good working condition.

Before using the fireplace, clear the area around it of any flammable materials, such as dry leaves, branches, or furniture. Never leave a fire unattended. Keep a fire extinguisher or a bucket of water nearby in case of emergency. Supervise children and pets closely when the fireplace is in use. Use only seasoned firewood, as green wood produces excessive smoke and creosote. Avoid burning trash, paper, or other materials that can release harmful chemicals into the air.

Regular maintenance is essential for keeping the fireplace in good working condition. Inspect the fireplace regularly for cracks, loose bricks, or other signs of damage. Repair any damage promptly to prevent further deterioration. Clean the firebox regularly to remove ashes and debris. Inspect the chimney liner for creosote buildup and have it professionally cleaned if necessary. Ensure that the area around the fireplace is free of obstructions and that the drainage system is functioning properly.

Specifically, cleaning the firebox diligently minimizes the risk of chimney fires. Creosote, a byproduct of burning wood, accumulates in the chimney and can ignite if not removed. A professional chimney sweep can inspect and clean the chimney liner annually. Furthermore, ensuring proper ventilation is crucial for safe and efficient combustion. Never use accelerants, such as gasoline or kerosene, to start a fire. These substances can cause dangerous flare-ups and explosions.

Troubleshooting Common Issues

Despite careful planning and construction, certain issues may arise with a cinder block fireplace. Understanding common problems and their solutions can help maintain the fireplace's functionality and safety.

One common issue is poor draft, which can result in smoke backing up into the seating area. This can be caused by a blocked chimney, insufficient chimney height, or downdrafts from nearby structures. Ensure the chimney is clear of obstructions and consider extending the chimney height if necessary. Installing a chimney cap can also help prevent downdrafts. Another potential cause of poor draft is an inadequate air supply to the firebox. Ensure the firebox opening is large enough and that there are no obstructions blocking the airflow.

Cracks in the cinder blocks or mortar joints are another common issue. These can be caused by thermal expansion and contraction, frost damage, or settling of the foundation. Small cracks can often be repaired with mortar patching, but larger cracks may require more extensive repairs. Frost damage can be minimized by ensuring the foundation is properly drained and by sealing the exterior of the fireplace with a waterproof coating. If the foundation is settling, it may be necessary to reinforce it or rebuild the fireplace on a more stable foundation.

Spalling, or crumbling, of the fire bricks is another potential problem. This is caused by the high temperatures of the fire and can eventually lead to the deterioration of the firebox. Replace damaged fire bricks promptly to prevent further damage. Using high-quality fire bricks and avoiding the use of excessively hot fires can help prolong the life of the firebox.

How To Make Your Own Fire Pit Artful Homemaking

Cinder Block Outdoor Fireplace Plans Approximate Dimensions 10 Wide 5 Deep 8 Tall Backyard Diy

Diy Square Cement Fire Pit On Sand

How We Built Our Outdoor Fireplace Chris Loves Julia

Build An Outdoor Fireplace The Shed

Backyard Fireplace Part 2 Milk Paint

Cinder Blick Fire Pit 4 X3 Under 50 Outdoor Designs Block Plans

Diy Outdoor Fireplace Block And Mortar

Saguaro Diy Outdoor Fireplace Plan

Diy Cinder Block Fire Pit

Related Posts