Candice Olson Fireplaces Incident Report: Analysis and Mitigation

The purpose of this report is to provide a detailed analysis of incidents linked to fireplaces designed or endorsed by Candice Olson, a prominent Canadian interior designer. These incidents primarily involve reported malfunctions, safety concerns, and instances where the fireplaces did not meet established safety standards or customer expectations. This report will examine the nature of these incidents, identify contributing factors, and propose potential mitigation strategies to prevent future occurrences. The report will focus on documented cases and publicly available information, adhering to a neutral and objective tone.

The term "Candice Olson Fireplaces" as used in this report refers to fireplaces that were either directly designed by Candice Olson or those that were marketed and sold featuring her endorsement or association. It is important to note that this report aims to analyze incidents related to these specific products and does not constitute a general assessment of all fireplaces available in the market.

Nature of Reported Incidents

Analysis of available incident reports reveals a range of issues associated with Candice Olson fireplaces. These issues are not universally reported across all models or installations but represent a collection of concerns raised by customers and, in some cases, regulatory bodies. The types of incidents can be broadly categorized as follows:

-

Malfunctioning Safety Features:

A recurring concern involves the failure of crucial safety features such as automatic shut-off mechanisms, gas leak detectors, and proper ventilation systems. These malfunctions can potentially lead to hazardous situations, including the accumulation of dangerous gases, the risk of fire spreading beyond the designated area, and the potential for carbon monoxide poisoning.-

Substandard Construction and Materials:

Several reports indicate the use of materials that are not adequately heat-resistant or durable for fireplace construction. This can lead to premature wear and tear, cracking, warping, and even structural failure of the fireplace over time. The selection of appropriate materials is critical for ensuring the long-term safety and performance of a fireplace.-

Installation Issues:

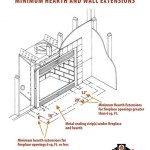

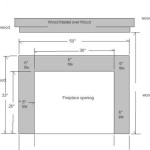

Improper installation of fireplaces is a significant contributing factor to reported incidents. Incorrect venting, insufficient clearance from combustible materials, and inadequate gas line connections can all compromise the safety and efficiency of the fireplace. Installation must comply with local building codes and manufacturer specifications.-

Compliance with Safety Standards:

Some reports have raised concerns about whether certain Candice Olson fireplace models fully comply with established safety standards and regulations. These standards are designed to ensure that fireplaces meet minimum requirements for safety, performance, and emissions. Non-compliance can expose users to increased risks and potential liability.-

Misleading Marketing and Product Claims:

Instances of alleged misleading marketing practices have also been reported. This includes claims about the energy efficiency, heating capacity, or safety features of the fireplaces that did not align with actual performance. Accurate and transparent marketing is essential for building consumer trust and avoiding potential legal issues.It's important to emphasize that the frequency and severity of these incidents vary. However, the consistent appearance of similar concerns across multiple reports suggests that these issues warrant further investigation and corrective action.

Contributing Factors to Incidents

Several factors may contribute to the reported incidents associated with Candice Olson fireplaces. These factors can be broadly categorized as design flaws, manufacturing defects, installation errors, and inadequate quality control measures.

-

Design Flaws:

The initial design of a fireplace plays a crucial role in its safety and performance. Design flaws can include inadequate ventilation systems, insufficient heat shielding, or the use of materials that are not suitable for the intended application. A thorough design review process is essential to identify and address potential safety concerns before production begins.-

Manufacturing Defects:

Manufacturing defects can arise from a variety of sources, including substandard materials, faulty components, and inadequate quality control during the manufacturing process. Rigorous quality control measures are necessary to ensure that each fireplace meets established specifications and safety standards.-

Installation Errors:

As previously mentioned, improper installation is a significant contributing factor to fireplace incidents. Installation errors can result from insufficient training of installers, failure to follow manufacturer instructions, or disregard for local building codes. Proper training, certification, and oversight of installers are crucial for preventing installation-related problems.-

Inadequate Quality Control:

Inadequate quality control throughout the design, manufacturing, and installation processes can allow defects and safety hazards to slip through undetected. Comprehensive quality control measures should include regular inspections, testing, and audits to ensure that all fireplaces meet established standards.-

Lack of Consumer Education:

Insufficient consumer education regarding the proper operation, maintenance, and safety precautions associated with fireplaces can also contribute to incidents. Clear and concise instructions, warning labels, and educational materials should be provided to consumers to help them use fireplaces safely and effectively.-

Supply Chain Issues:

Changes in suppliers or sourcing of components can sometimes lead to inconsistencies in quality and performance. Maintaining a robust supply chain management system is essential for ensuring that all components meet the required standards.Potential Mitigation Strategies

To mitigate the risk of future incidents involving Candice Olson fireplaces, a multi-faceted approach is necessary. This approach should address design flaws, manufacturing defects, installation errors, inadequate quality control, and lack of consumer education. The following strategies are recommended:

-

Comprehensive Design Review:

Conduct a thorough review of the design of all Candice Olson fireplace models to identify and address potential safety concerns. This review should involve independent engineers and safety experts to ensure objectivity and expertise.-

Enhanced Quality Control Measures:

Implement enhanced quality control measures throughout the manufacturing process. This should include regular inspections, testing, and audits to identify and correct any defects or inconsistencies. All components should be sourced from reputable suppliers and subjected to rigorous testing before being incorporated into the fireplaces.-

Installer Training and Certification:

Develop and implement a comprehensive training and certification program for fireplace installers. This program should cover all aspects of fireplace installation, including proper venting, gas line connections, and compliance with local building codes. Only certified installers should be authorized to install Candice Olson fireplaces.-

Improved Consumer Education:

Develop and disseminate clear and concise educational materials to consumers regarding the proper operation, maintenance, and safety precautions associated with fireplaces. This should include instructions on how to detect gas leaks, how to maintain proper ventilation, and what to do in the event of an emergency. Consider using online resources, videos, and printed materials to reach a wider audience.-

Regular Safety Audits:

Conduct regular safety audits of installed Candice Olson fireplaces to identify potential problems and ensure compliance with safety standards. These audits should be performed by qualified professionals and should include inspections of all critical components and safety features.-

Transparent Communication:

Establish a transparent communication channel for consumers to report concerns or incidents related to Candice Olson fireplaces. All reports should be investigated promptly and thoroughly, and appropriate corrective action should be taken.-

Compliance with Regulatory Standards:

Ensure that all Candice Olson fireplace models fully comply with all applicable safety standards and regulations. This should include regular testing and certification by independent testing laboratories. Stay informed about changes in regulations and update designs and manufacturing processes accordingly.-

Supply Chain Management Optimization:

Implement a robust supply chain management system to ensure the consistent quality and performance of all components used in Candice Olson fireplaces. This should include regular audits of suppliers and testing of incoming materials.-

Recalls and Remediation:

If necessary, initiate recalls of affected fireplace models to address known safety concerns. Develop and implement a remediation plan to correct any defects or hazards in recalled fireplaces. Communicate clearly and transparently with consumers about the recall and remediation process.By implementing these mitigation strategies, it is possible to significantly reduce the risk of future incidents involving Candice Olson fireplaces and enhance the safety and satisfaction of consumers.

105 Candice Olson Living Room Design

Candice Olson Master Bedroom Ventless Fireplace

Candice Olson Fabric L A Design Concepts

Divine Design Basement Crosses The Finish Line

What Happened To Candice Olson From Divine Design Where Is She Now

Kids Playroom Becomes Fun For All Ages Orange County Register

Candice Olson Master Bedroom Ventless Fireplace

A Great Room Finally Lives Up To Its Name Orange County Register

What Happened To Candice Olson Why The Divine Design Host Disappeared From

Candice Olson Dining Room Gets Dressed Up

Related Posts