Can A Fireplace Flue Be Repaired? Understanding Flue Repair Options and Considerations

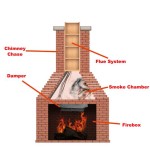

The fireplace flue, a critical component of any functioning fireplace, is responsible for safely venting combustion byproducts, such as smoke, carbon monoxide, and creosote, out of the building. Over time and with repeated use, flues can deteriorate due to exposure to high temperatures, corrosive combustion gases, and the elements. Determining whether a flue can be repaired versus replaced is an important decision that affects safety, efficiency, and cost. This article will explore the various repair options available for fireplace flues, the factors influencing the repair versus replacement decision, and considerations for ensuring a safe and effective outcome.

A thorough inspection by a qualified chimney sweep or professional is the initial step in assessing the condition of a fireplace flue. This inspection should involve a visual examination, often aided by video scanning equipment, to identify cracks, spalling (surface crumbling), mortar joint deterioration, and other signs of damage. The inspection will also look for obstructions, such as bird nests or creosote buildup, which can impede proper airflow and increase the risk of chimney fires. The extent and nature of the damage, along with the age and construction of the chimney, will dictate the appropriate course of action.

It's crucial to understand that neglecting flue repairs can lead to significant safety hazards. A damaged flue can allow dangerous gases to seep into the living space, posing a carbon monoxide poisoning risk. Additionally, cracks and gaps in the flue can enable hot embers and flames to ignite combustible materials within the chimney structure or surrounding walls, leading to a chimney fire. Addressing flue issues promptly is therefore essential for maintaining a safe and functional fireplace.

Key Point 1: Common Types of Fireplace Flue Damage and Repair Methods

Fireplace flues are constructed from a variety of materials, including clay tiles, metal liners (stainless steel or aluminum), and cast iron. The type of material and the specific construction methods used will influence the types of damage that are likely to occur. Identifying the nature of the damage is crucial for selecting the appropriate repair technique.

Clay Tile Flues: These are among the most common types of flue linings, particularly in older homes. Clay tiles are generally durable but can crack or break due to thermal shock (rapid temperature changes), settling of the chimney structure, or moisture penetration. Cracks in clay tiles, especially if they are small and superficial, can sometimes be repaired using specialized flue sealants. These sealants are designed to withstand high temperatures and create a barrier that prevents gases from escaping. However, if the tiles are severely cracked, crumbling, or missing entirely, a full relining is generally recommended.

Metal Flue Liners: Metal liners, typically made from stainless steel or aluminum, are used to reline existing chimneys or as part of new fireplace installations. Stainless steel liners are more durable and resistant to corrosion than aluminum liners, making them suitable for wood-burning fireplaces. Aluminum liners are generally used with gas-burning appliances. Metal liners can suffer from corrosion, dents, and breaches over time. Small holes or corroded areas can sometimes be patched, but larger areas of damage usually necessitate replacement of the entire liner.

Cast Iron Flues: Cast iron flues are often found in older buildings and are known for their durability. However, they can be susceptible to rust and cracking, particularly at the joints. Repairing cast iron flues typically involves patching cracks with high-temperature mortar or epoxy. In severe cases, sections of the cast iron flue may need to be replaced. Replacing sections can be complex and requires specialized skills.

Mortar Joint Deterioration: The mortar joints between flue tiles or sections are susceptible to deterioration over time due to exposure to moisture and combustion gases. Crumbling or missing mortar can create gaps that allow gases to escape. Tuckpointing, which involves removing and replacing damaged mortar, is a common repair technique for addressing this issue. Tuckpointing can restore the structural integrity of the flue and prevent gas leakage.

Flue Sealants: Specialized flue sealants are available for repairing small cracks and gaps in flue liners. These sealants are typically applied as a coating that fills the cracks and creates a smooth, airtight surface. Flue sealants are a relatively inexpensive repair option for minor damage, but they are not a substitute for a full relining when the damage is extensive.

Key Point 2: Factors Influencing the Repair vs. Replacement Decision

The decision to repair or replace a fireplace flue is multifaceted and depends on a variety of factors. Carefully evaluating these factors is critical for making an informed choice that ensures safety and cost-effectiveness. There isn't a one-size-fits-all approach; each situation must be assessed individually.

Severity of Damage: The primary factor influencing the repair versus replacement decision is the extent of the damage to the flue. Minor cracks, spalling, or mortar joint deterioration may be effectively addressed with repair techniques such as flue sealants or tuckpointing. However, if the flue is severely cracked, crumbling, or has large sections missing, replacement is generally the only viable option. Attempting to repair extensive damage may be a short-term fix that does not address the underlying issues and could ultimately lead to a more dangerous situation.

Age of the Chimney: The age of the chimney and the type of construction materials used can also influence the decision. Older chimneys may be more prone to extensive damage and may require more comprehensive repairs or replacement. If the chimney is nearing the end of its useful life, replacing the flue may be a more cost-effective solution in the long run than attempting to repair it.

Type of Fuel Used: The type of fuel burned in the fireplace can impact the rate of flue deterioration. Wood-burning fireplaces tend to produce more creosote, a highly flammable substance that can accumulate in the flue and contribute to chimney fires. Gas-burning fireplaces produce less creosote but can still generate corrosive gases that can damage the flue liner. The type of fuel used should be considered when selecting repair or replacement options.

Cost Considerations: The cost of repair versus replacement is an important factor for most homeowners. Repairs are generally less expensive than replacement, but they may not be a long-term solution if the underlying issues are not addressed. Replacement, while more expensive upfront, may provide a more durable and reliable solution that can save money in the long run by preventing future repairs and safety hazards. Obtaining multiple quotes from qualified professionals is crucial for comparing the costs of different options.

Building Codes and Regulations: Local building codes and regulations may dictate the type of repair or replacement that is required. Some jurisdictions may require homeowners to bring their chimneys up to current code standards when performing major repairs or replacements. Consulting with local building officials is essential for ensuring compliance with all applicable regulations.

Safety Concerns: Safety is always the paramount consideration when dealing with fireplace flues. If there is any doubt about the structural integrity of the flue or the effectiveness of a repair, replacement is the safer option. A compromised flue can pose a serious risk of carbon monoxide poisoning or chimney fire. Prioritizing safety should always be the guiding principle.

Key Point 3: The Flue Relining Process and Alternative Repair Techniques

When flue replacement is deemed necessary, the most common approach is to reline the chimney with a new liner. Flue relining involves installing a new metal liner inside the existing chimney structure. This process can significantly improve the safety and efficiency of the fireplace.

Flue Relining with Metal Liners: The most common method of flue relining involves installing a flexible or rigid stainless steel liner inside the existing chimney. The process typically begins with cleaning the chimney to remove any debris or creosote buildup. The new liner is then carefully lowered into the chimney and connected to the fireplace appliance. The space between the liner and the chimney walls is often filled with insulation to improve thermal efficiency and prevent condensation. Stainless steel liners are durable, resistant to corrosion, and provide a safe and effective way to vent combustion gases.

Cast-in-Place Liners: An alternative to metal liners is the cast-in-place liner. This involves pouring a special concrete-like mixture into the chimney flue to create a seamless, airtight liner. Cast-in-place liners are known for their durability and insulating properties. The process typically involves inserting a form into the chimney flue and then pouring the mixture around the form. Once the mixture has hardened, the form is removed, leaving a smooth, continuous liner. Cast-in-place liners are often used in situations where the chimney is severely damaged or where a custom-fit liner is required.

Spray-on Coatings: In some cases, spray-on coatings can be used to repair minor cracks and gaps in flue liners. These coatings are typically applied as a liquid that hardens to form a durable, protective layer. Spray-on coatings are a relatively inexpensive repair option, but they are not a substitute for a full relining when the damage is extensive. They are best suited for addressing small imperfections and preventing further deterioration of the flue liner.

Smoke Chamber Repair: The smoke chamber, located above the firebox, is another area of the chimney that can be prone to damage. The smoke chamber is responsible for channeling smoke from the firebox into the flue. Over time, the smoke chamber can develop cracks or gaps that allow smoke and gases to escape. Repairing the smoke chamber involves patching cracks with high-temperature mortar or applying a specialized coating to create a smooth, airtight surface. A properly sealed smoke chamber is essential for ensuring efficient and safe fireplace operation.

Professional Installation: Regardless of the repair or replacement method chosen, it is essential to hire a qualified and experienced chimney sweep or contractor to perform the work. Proper installation is critical for ensuring the safety and efficiency of the fireplace. A professional can assess the condition of the chimney, recommend the appropriate repair or replacement option, and perform the work in accordance with local building codes and regulations. Neglecting to use a qualified professional can lead to improper installation, which can compromise safety and void warranties.

Ultimately, determining whether a fireplace flue can be repaired is a decision that requires careful consideration of the extent of the damage, the age of the chimney, the type of fuel used, cost considerations, and local building codes. Consulting with a qualified professional is essential for making an informed decision and ensuring a safe and effective outcome. Prioritizing safety and adhering to best practices are crucial for maintaining a functional and reliable fireplace.

Flue Repairs And Chimney Relining A 1 Pro

Chimney Lining Repair Systems Heatshield

Flue Repairs And Chimney Relining A 1 Pro

Joint Repair In A Flue Liner Maintenance Waterproofing 423 398 1632

Heatshield Relining Charlotte Nc Owens Chimney Systems

Easily Solve These Common Chimney Repair Problems Chimneysaver

Chimney Repair Cost To Fix A Fixr

Chimney Repair Milwaee Wi Concepts

Damper Repair Replacement Cherry Hill Mason S Chimney Serivce

Nicholas Chimney Sweeping Stove Fireplace Services Vienna Virginia